CPS Question and answers

| Que.No | Question/Problem | marks | Link |

|---|---|---|---|

| Q ) |

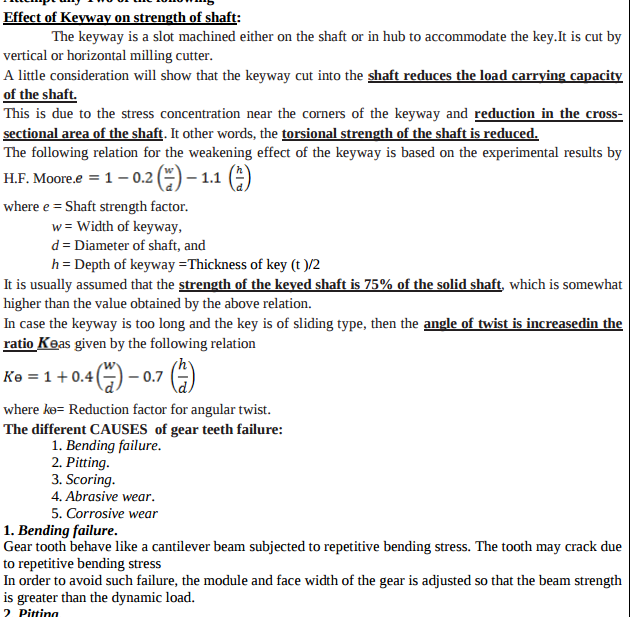

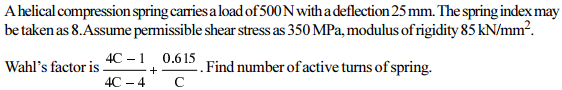

Question:

State one application of each : v-belt drive, flat belt drive, chain drive and gear drive. Answer:

|

4 |

view |

| Q 3 a ) |

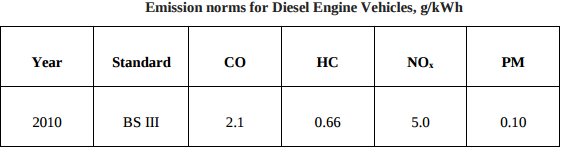

Question:

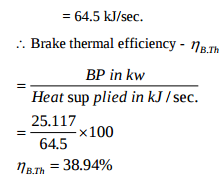

State the norms of Bharat stage III and IV. Answer:

|

4 |

view |

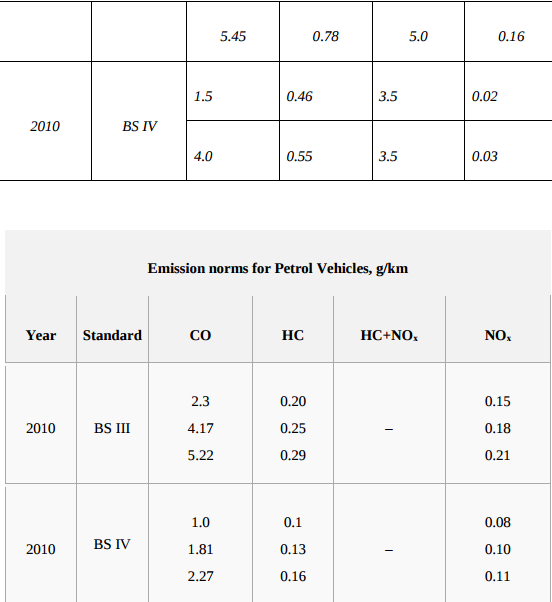

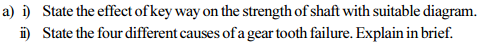

| Q 4a)(iii) |

Question:

State the effect of keyway on the strength of the shaft. Answer:

|

4 |

view |

| Q 5 c ) |

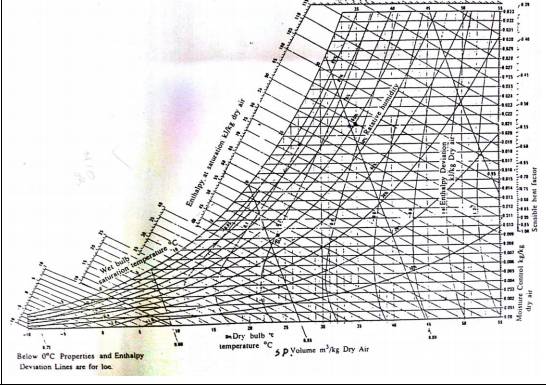

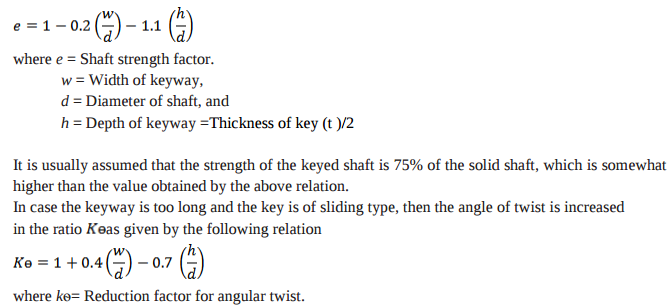

Question:

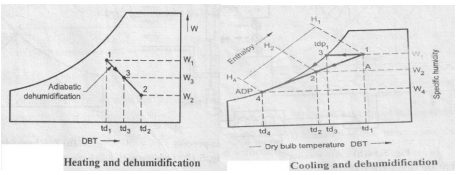

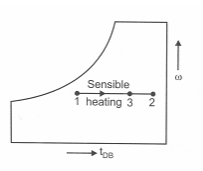

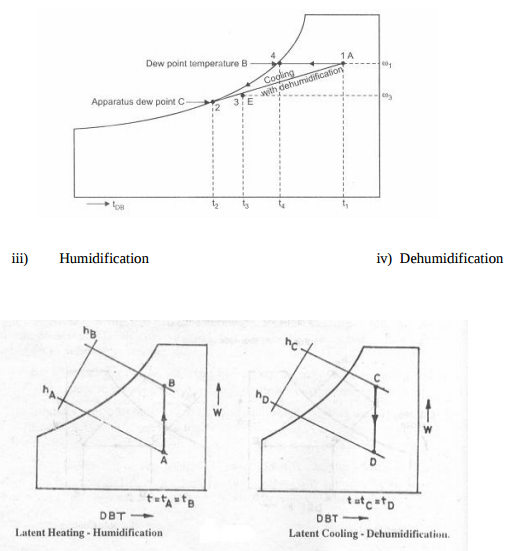

Draw psychrometric chart with all the property lines and represent following psychrometric Answer:

|

8 |

view |

| Q 6 b ) |

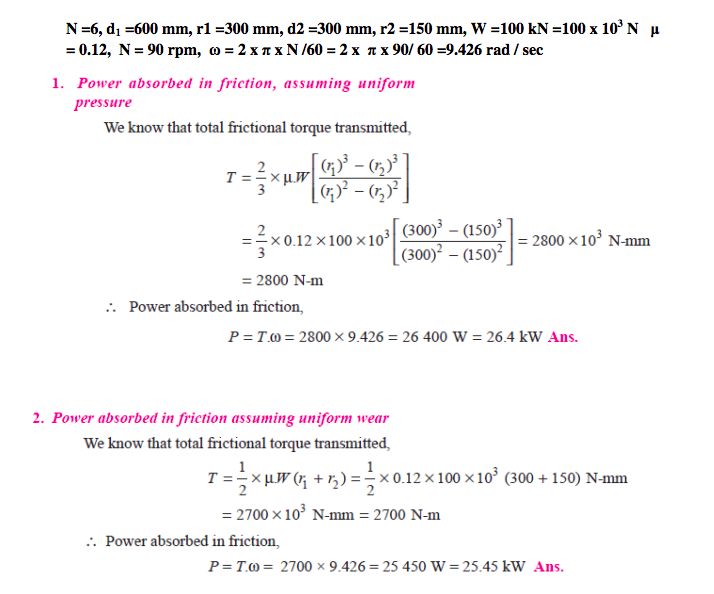

Question:

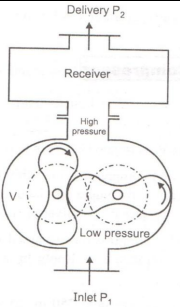

Define : i) Free air delivered ii) Compressor capacity iii) Swept volume iv) Pressure ratio, w.r.to compressor. Answer:

|

4 |

view |

| Que.No | Question/Problem | marks | Link |

|---|---|---|---|

| Q 1 a ) |

Question:

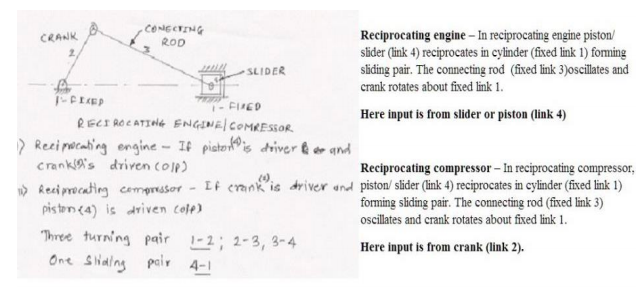

Define inversion with example. Answer:

|

2 |

view |

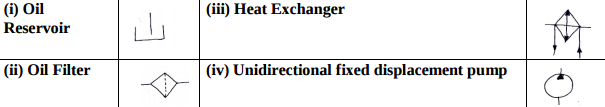

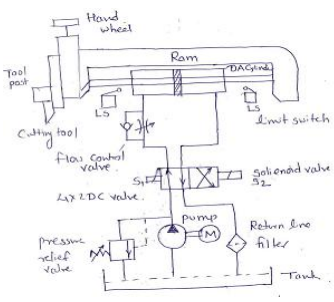

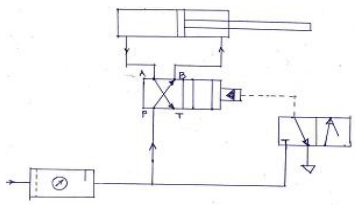

| Q 1a)(a) |

Question:

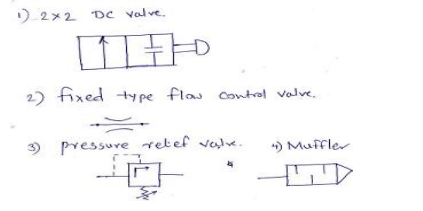

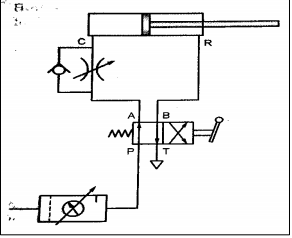

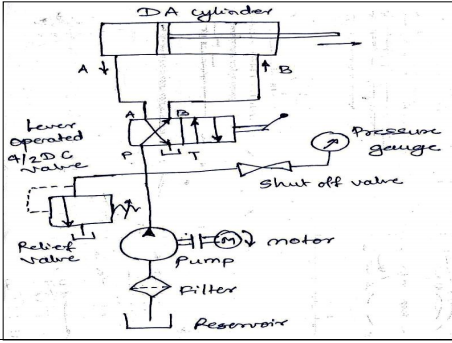

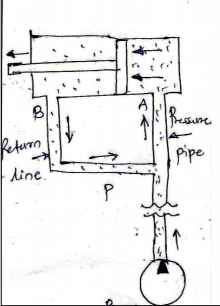

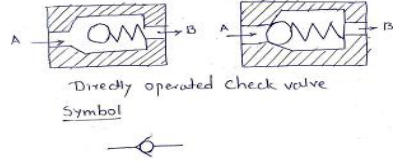

What is function of (i) oil reservoir (ii) pressure relief valve, (iii) direction control valve, (iv) filters ? Answer:

|

4 |

view |

| Q 1a)(a) |

Question:

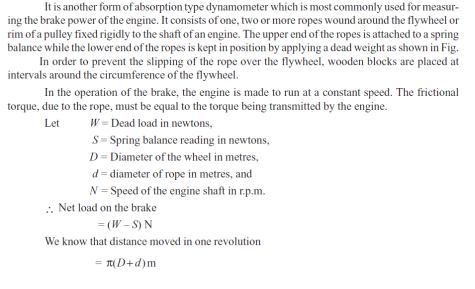

Enlist uses of compressed air (any four). Answer:

|

4 |

view |

| Q 1a)(b) |

Question:

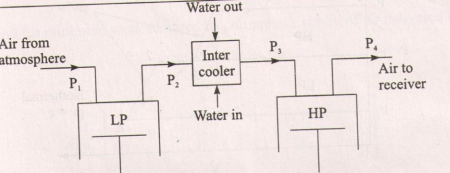

What are the advantages of multistaging ? Answer:

|

4 |

view |

| Q 1a)(b) |

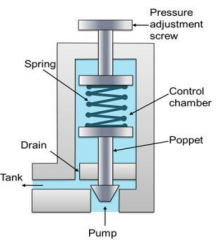

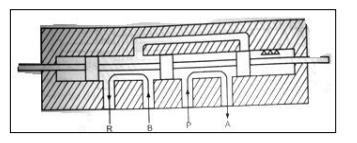

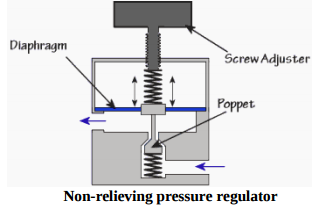

Question:

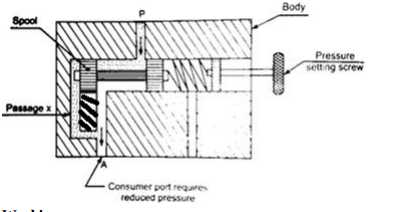

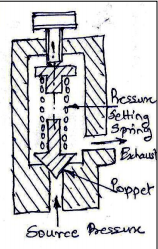

Draw and explain working of pressure reducing valve. Answer:

|

4 |

view |

| Q 1a)(c) |

Question:

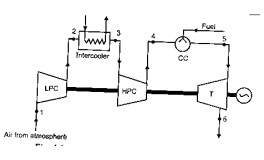

Classify gas turbines (any four) Answer:

|

4 |

view |

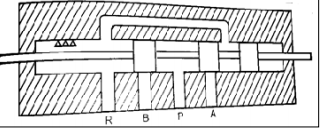

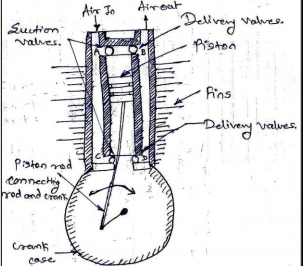

| Q 1a)(c) |

Question:

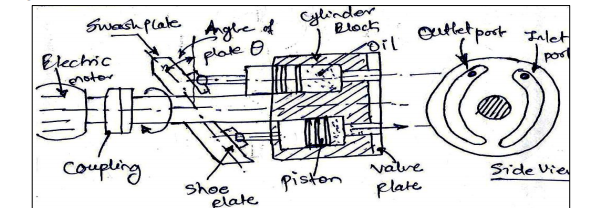

Explain piston pump with neat sketch. Answer:

|

4 |

view |

| Q 1a)(d) |

Question:

What is an accumulator ? Why accumulator is necessary for huge hydraulic pressers ? Answer:

|

4 |

view |

| Q 1a)(d) |

Question:

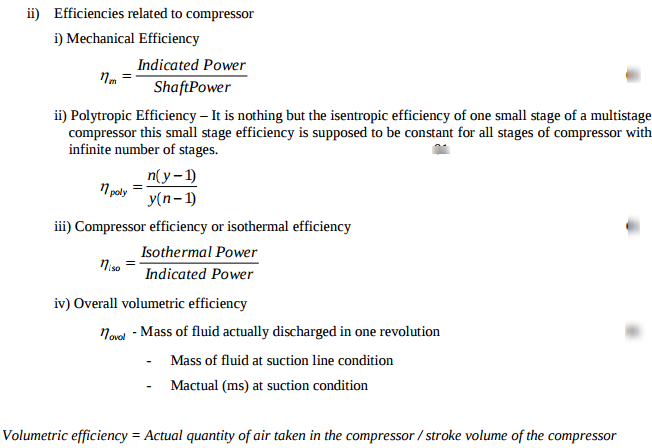

Define : Answer:

|

4 |

view |

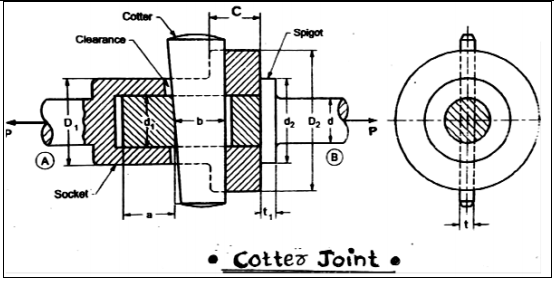

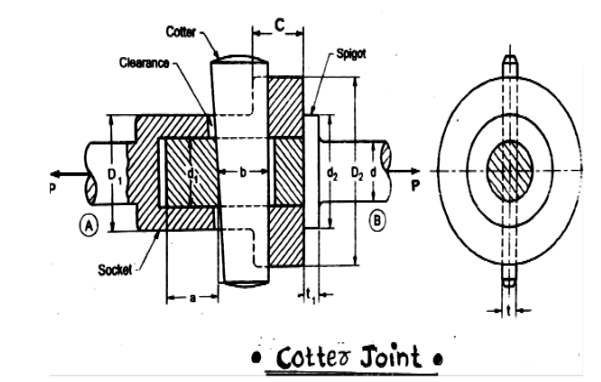

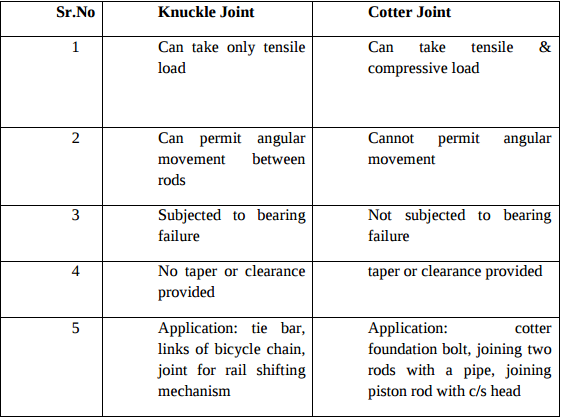

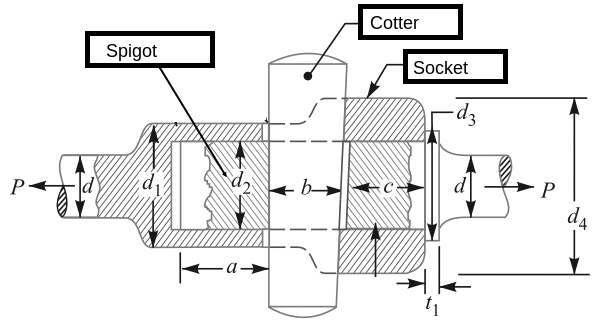

| Q 1a)(ii) |

Question:

What is a cotter joint? State any four applications of a cotter joint? Why taper is provided on cotter joint? Answer:

|

8 |

view |

| Q 1a)(iii) |

Question:

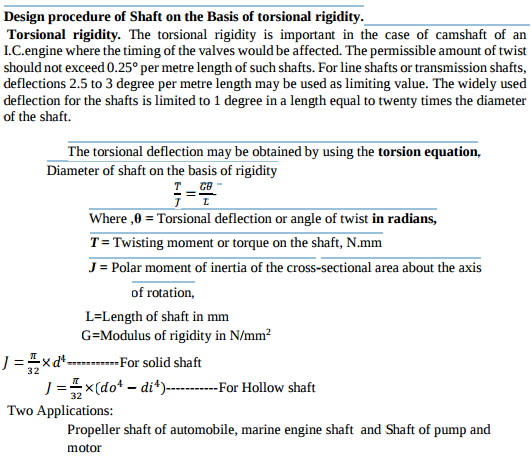

A hollow shaft for a rotary compressor is to be designed to transmit maximum torque of 4750 N-m. The shear stress in the shaft is limited to 50 MPa. Determine the inside outside diameter of the shaft if the ratio of inside to outside diameter of the shaft is 0.4. Answer:

|

8 |

view |

| Q 1 b ) |

Question:

List the inversions for double slider crank mechanism. Answer:

|

2 |

view |

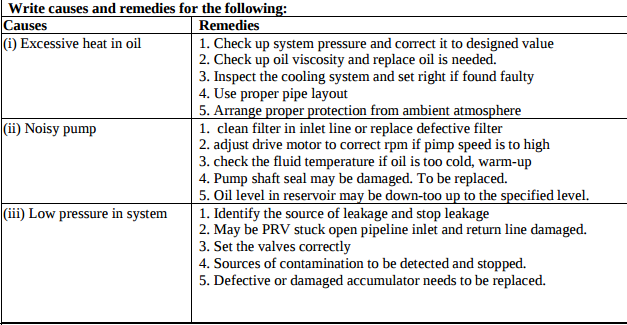

| Q 1b)(a) |

Question:

Write the causes and remedies for the following : (i) Excess heat in oil (ii) Noisy pump (iii) Low pressure in system. Answer:

|

6 |

view |

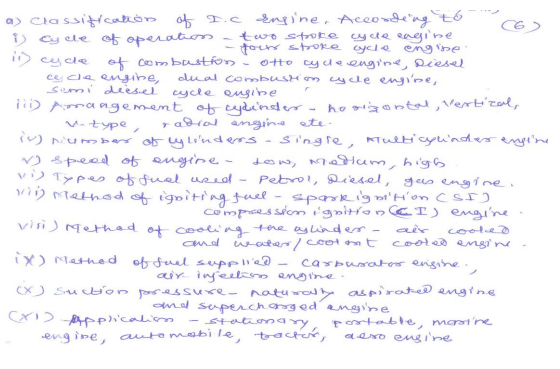

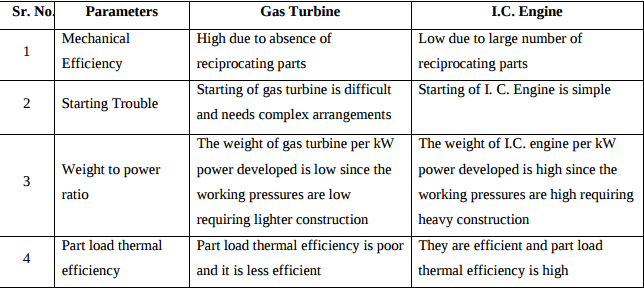

| Q 1b)(a) |

Question:

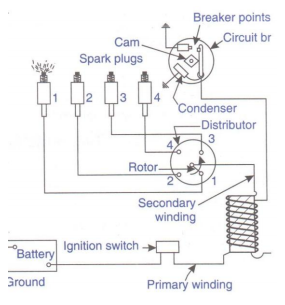

Give classification of IC engines (any six). Answer:

|

6 |

view |

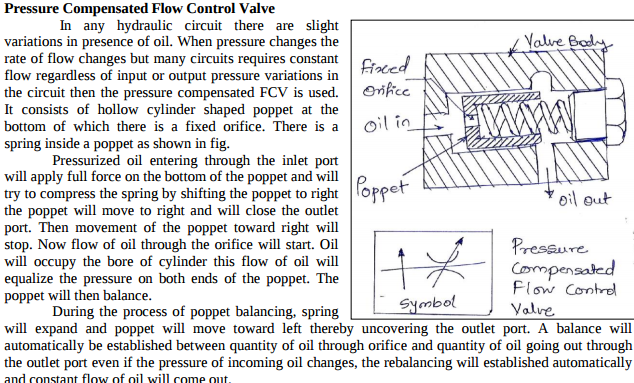

| Q 1b)(b) |

Question:

What is pressure compensated flow control valve ? Explain with sketch. Answer:

|

6 |

view |

| Q 1b)(b) |

Question:

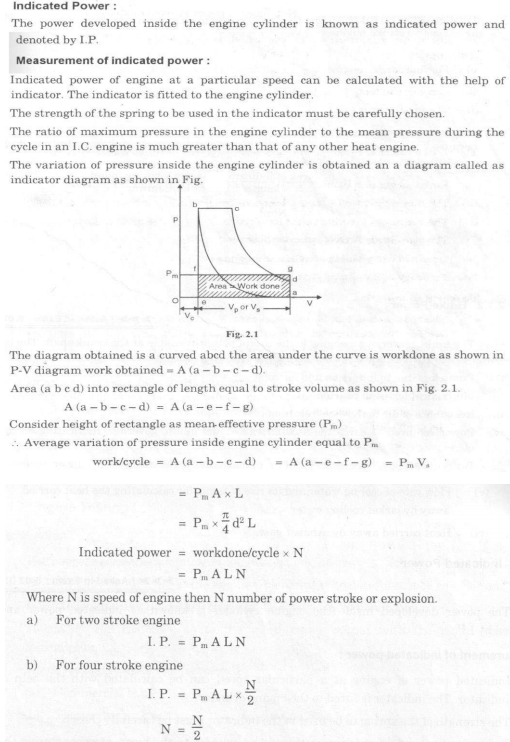

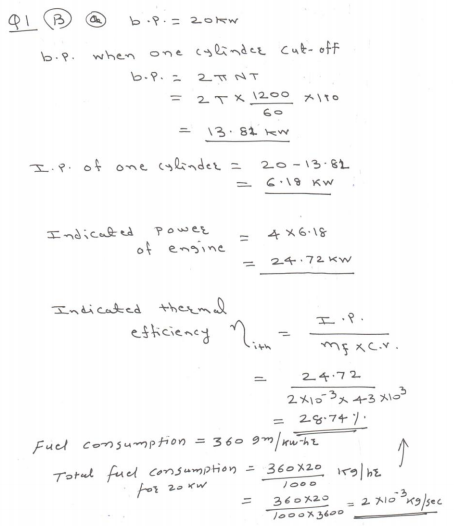

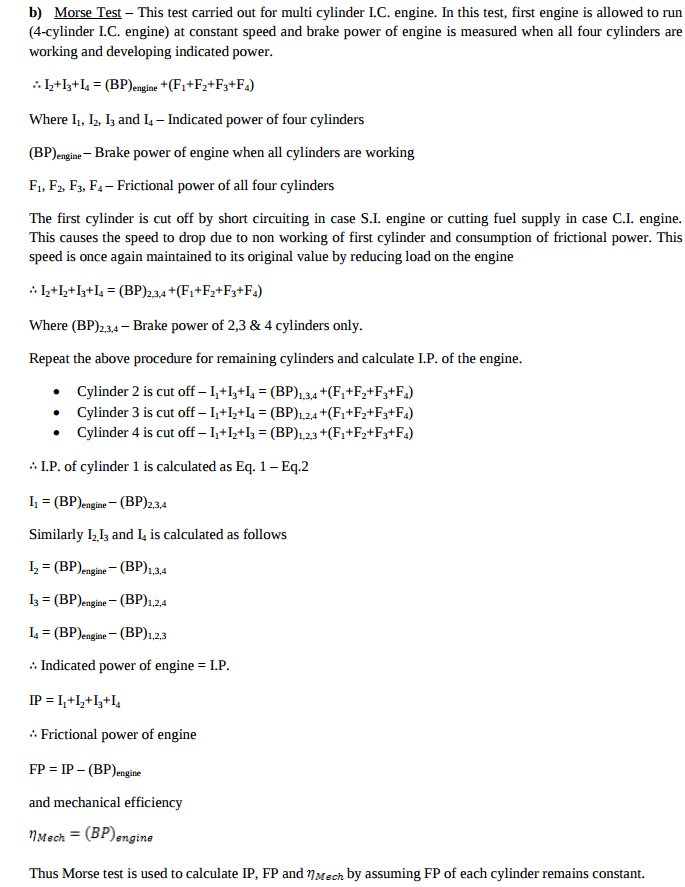

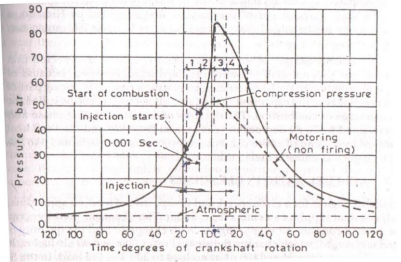

Explain Morse test conducted to find the frictional power of a multi-cylinder petrol engine Answer:

|

6 |

view |

| Q 1b)(i) |

Question:

i) What are the factors to be considered for selection of materials for design of machine elements? Answer:

|

6 |

view |

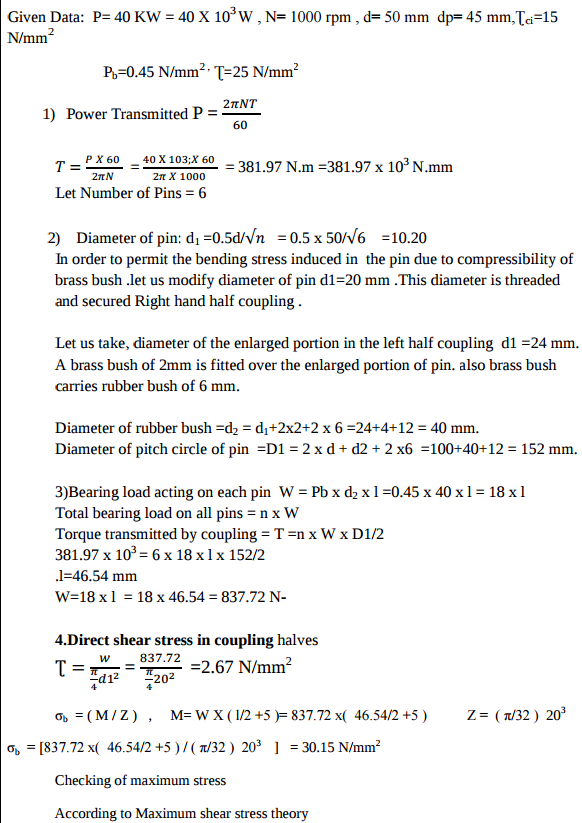

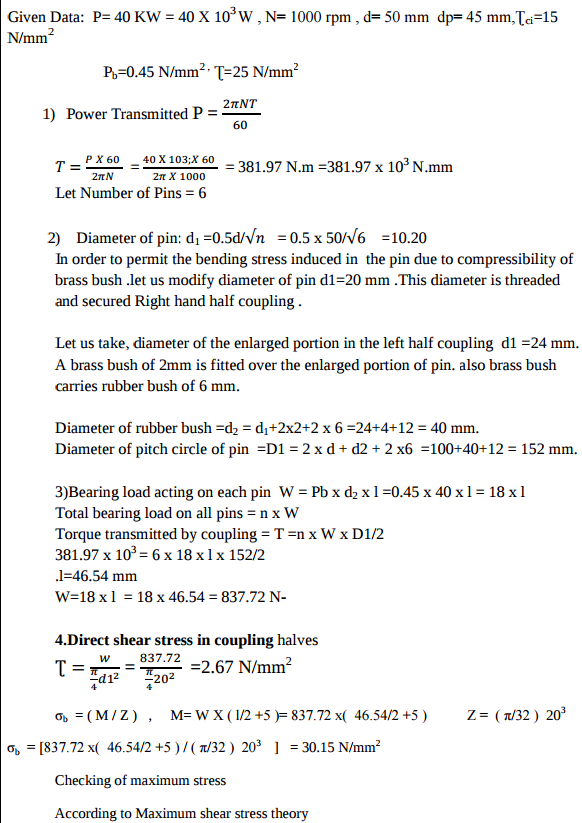

| Q 1b)(ii) |

Question:

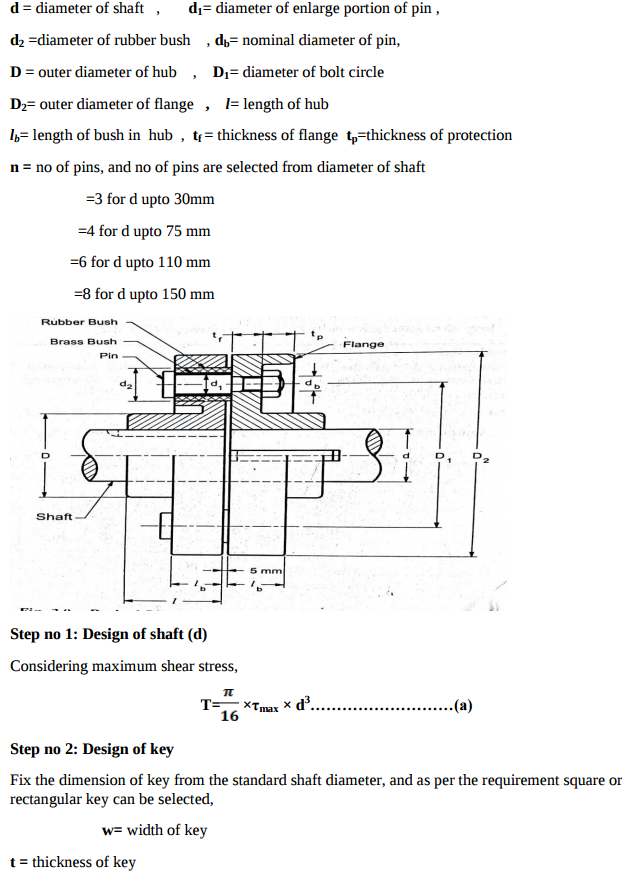

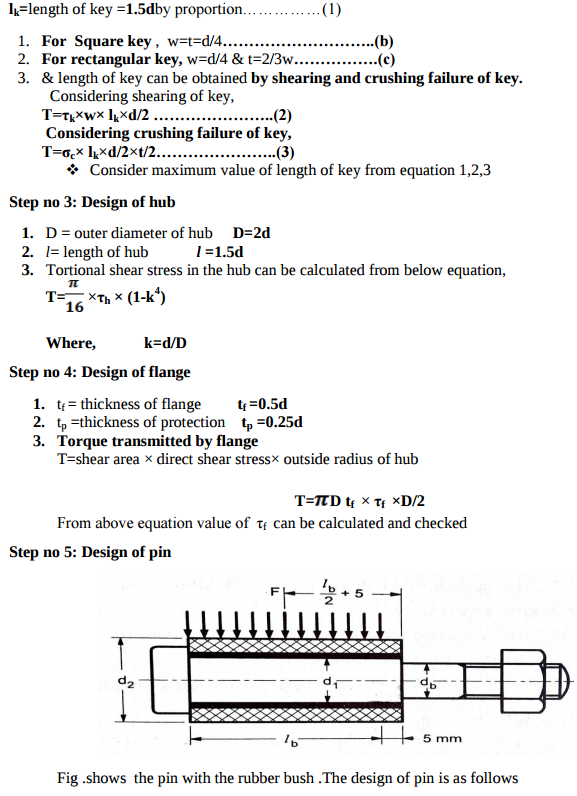

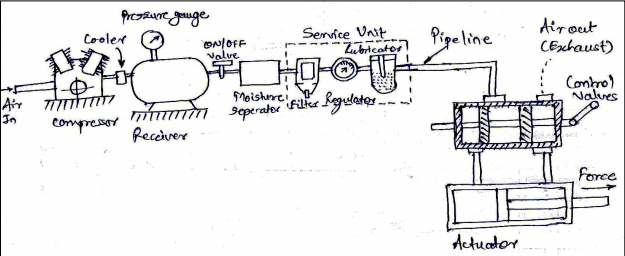

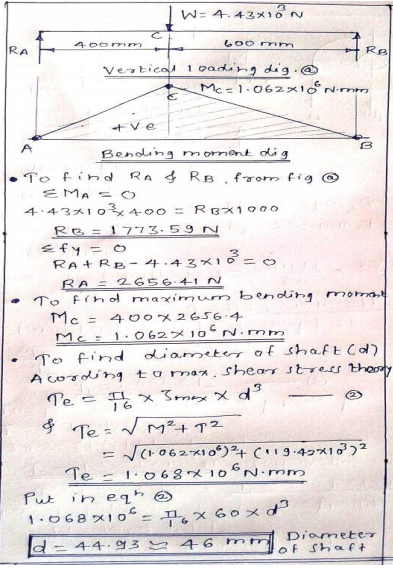

Design a bushed pin type flexible coupling for connecting a motor shaft to a pump shaft for the following service conditions. Power to be transmitted = 40 KW. Speed of the motor shaft = 1000 RPM. Diameter of the motor shaft = 50 mm Diameter of the pump shaft = 45 mm The bearing pressure in the rubber bush and allowable stress in the pins are to be limited to 0.45 N/mm2 and 25 MPa respectively Answer:

|

6 |

view |

| Q 1 c ) |

Question:

Define sliding pair with example. Answer:

|

2 |

view |

| Q 1 d ) |

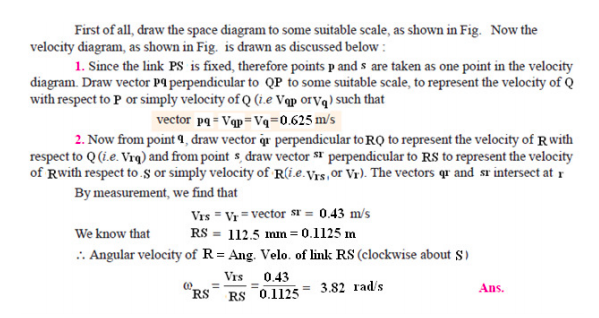

Question:

Define centripetal and tangential acceleration. Answer:

|

2 |

view |

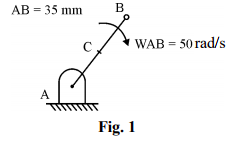

| Q 1 e ) |

Question:

Find the velocity of point B and midpoint C of link AB shown in Figure (1). Answer:

|

2 |

view |

| Q 1 f ) |

Question:

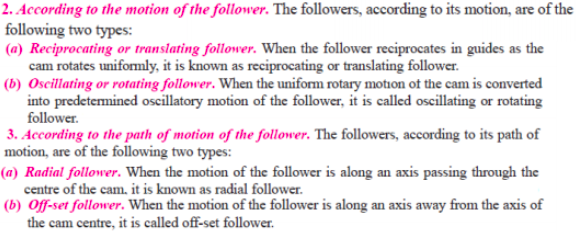

Classify the cam. Answer:

|

2 |

view |

| Q 1 g ) |

Question:

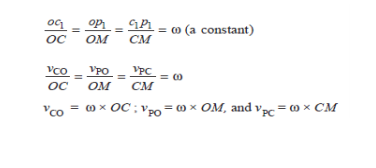

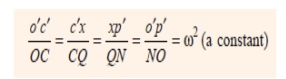

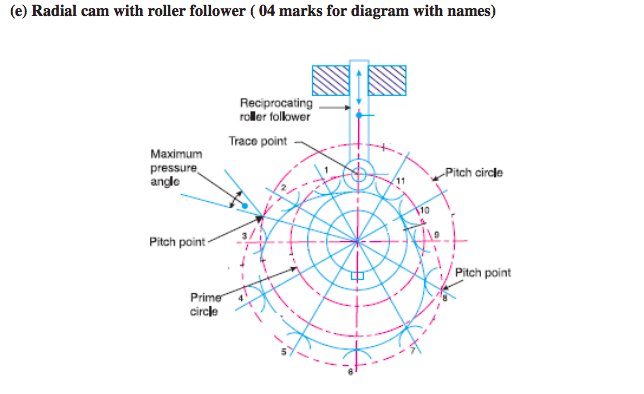

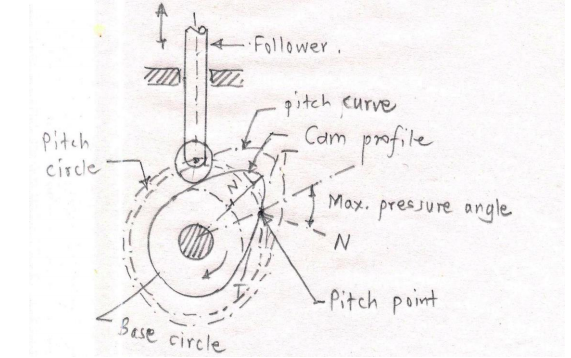

Define following terms with respect to cam and follower : (i) Prime circle (ii) Pitch circle (iii) Pressure angle (iv) Trace point

Answer:

|

2 |

view |

| Q 1 h ) |

Question:

What are the limitations of knife edge follower ? Answer:

|

2 |

view |

| Q 1 i ) |

Question:

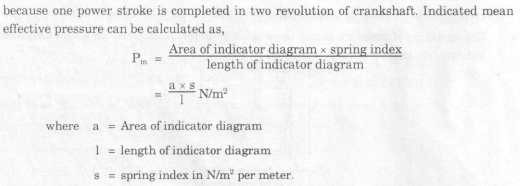

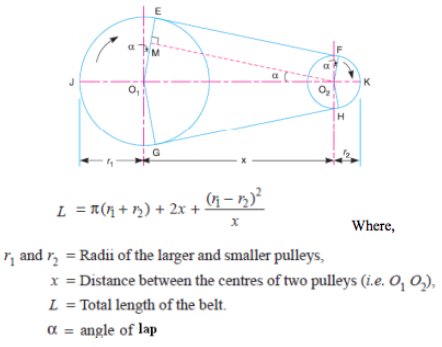

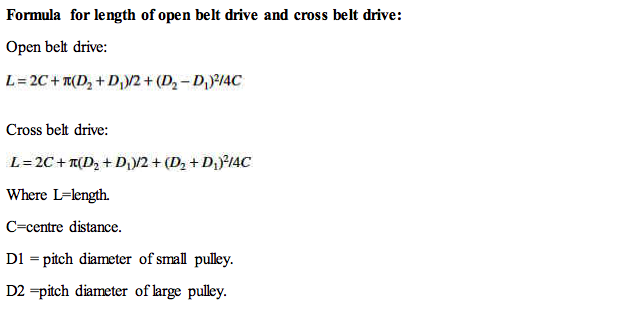

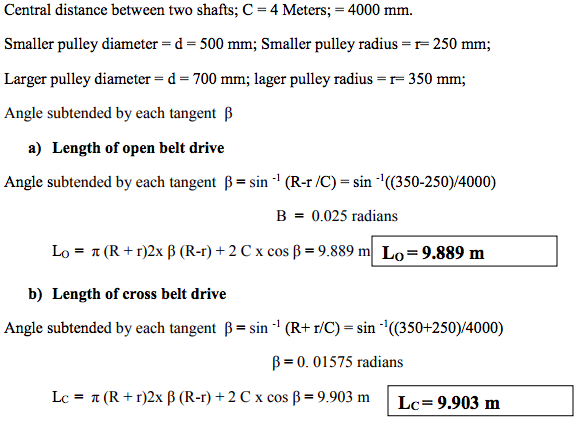

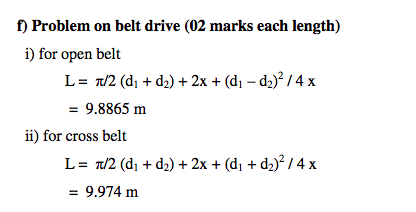

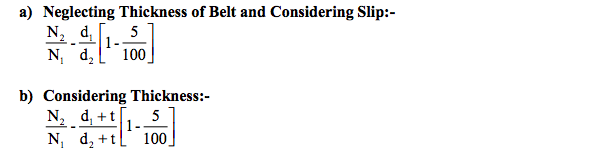

Write down the formula of length of belt for open belt drive and cross belt drive. Answer:

|

2 |

view |

| Q 1 i ) |

Question:

List the methods to reduce the slip in belt and pulley. Answer:

|

2 |

view |

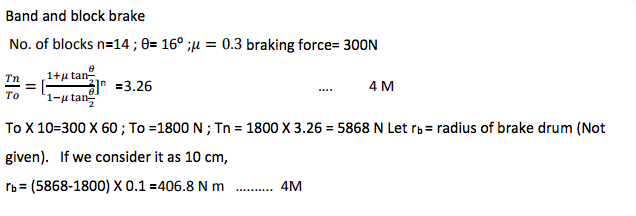

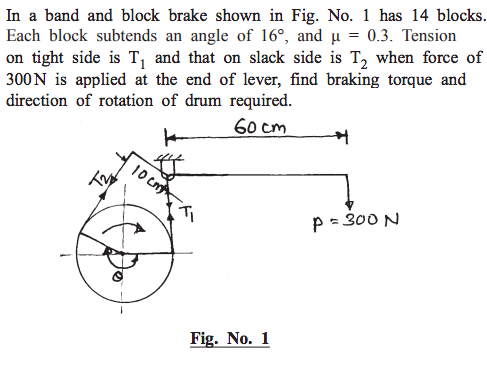

| Q 1 i ) |

Question:

Define self-energizing and self-locking brake. Answer:

|

2 |

view |

| Q 1 k ) |

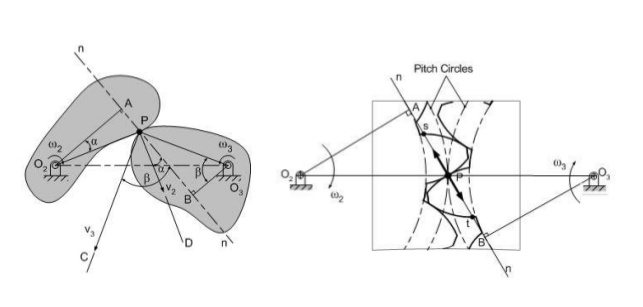

Question:

Define law of gearing. Answer:

|

2 |

view |

| Q 1 l ) |

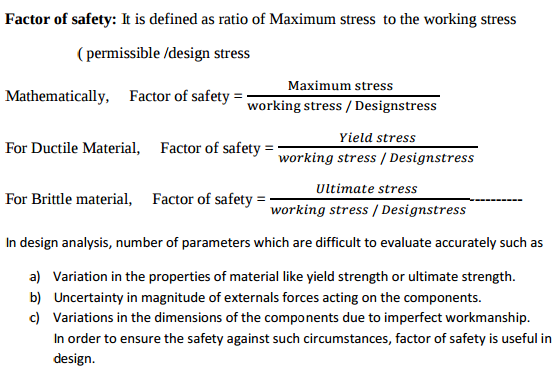

Question:

What is factor of safety? State its importance in design of machine elements. Answer:

|

8 |

view |

| Q 1 m ) |

Question:

What are the limitations of shoe brake ? Answer:

|

2 |

view |

| Q 1 n ) |

Question:

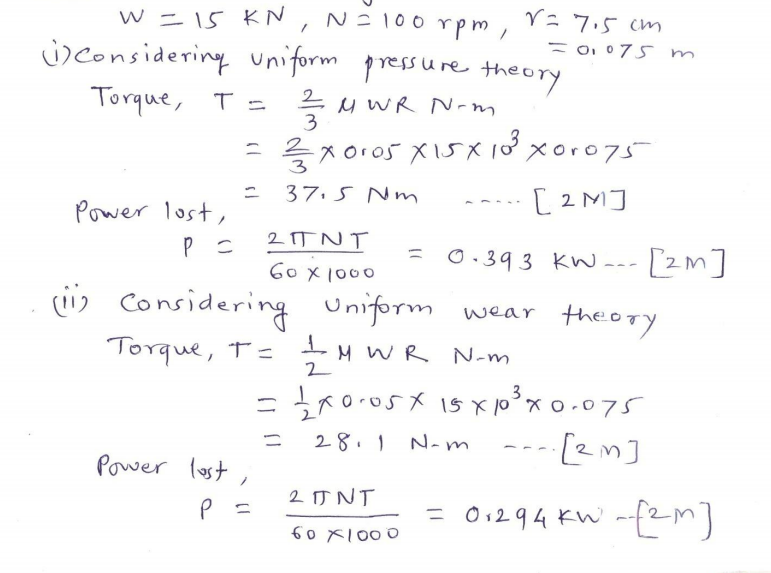

Define uniform wear theory and uniform pressure theory. Answer:

|

2 |

view |

| Q 1 o ) |

Question:

State effects of imbalance in machine. Answer:

|

2 |

view |

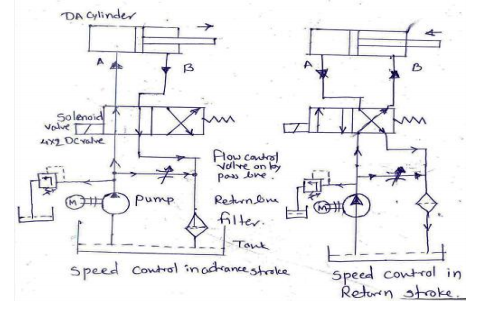

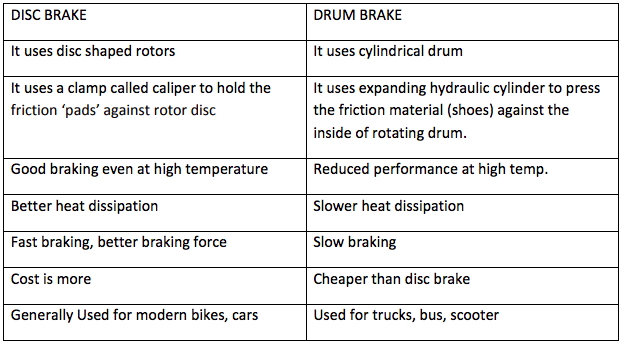

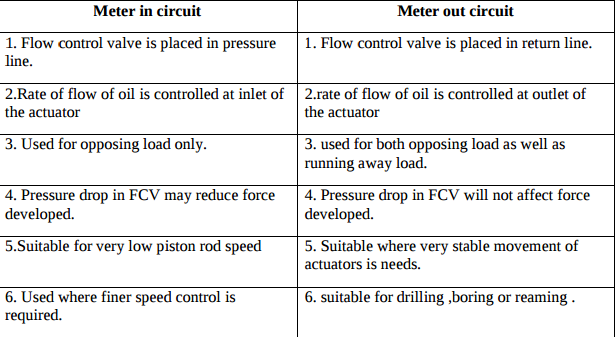

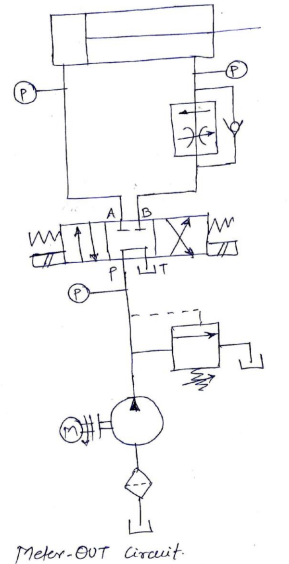

| Q 2 a ) |

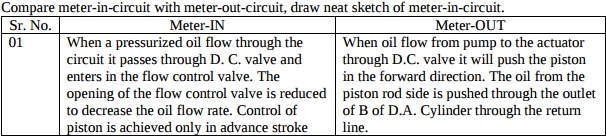

Question:

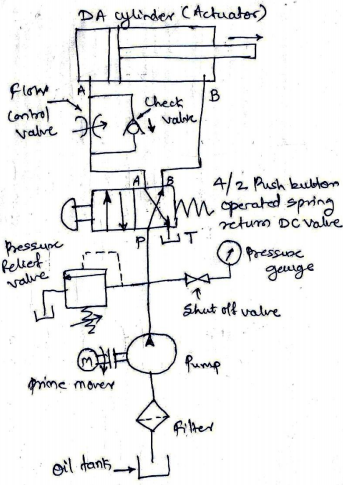

Compare meter-in-circuit with meter-out-circuit, draw neat sketch of meter-in-circuit. Answer:

|

8 |

view |

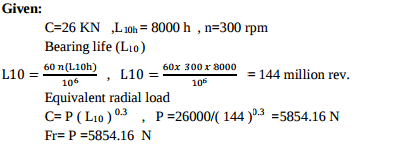

| Q 2 a ) |

Question:

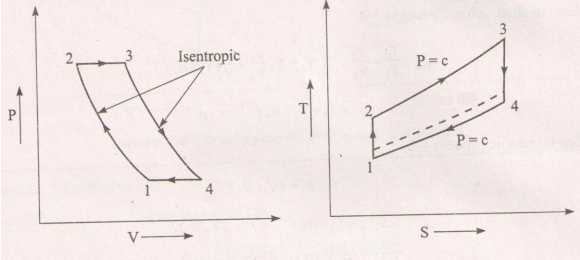

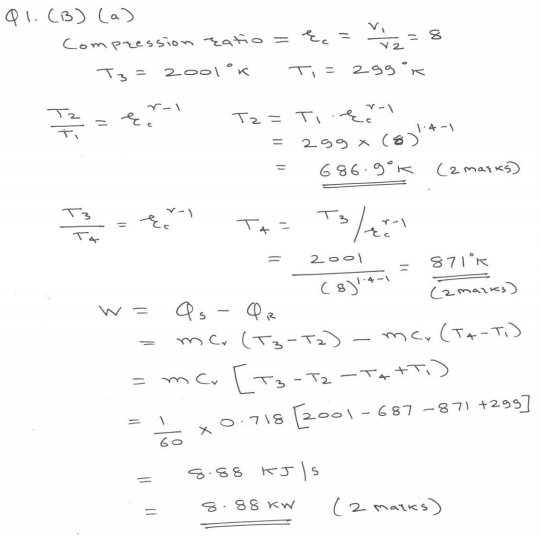

In an Ideal ottocycle the air at the beginning of isentropic compression is at 1.01325 bar and Answer:

|

8 |

view |

| Q 2 a ) |

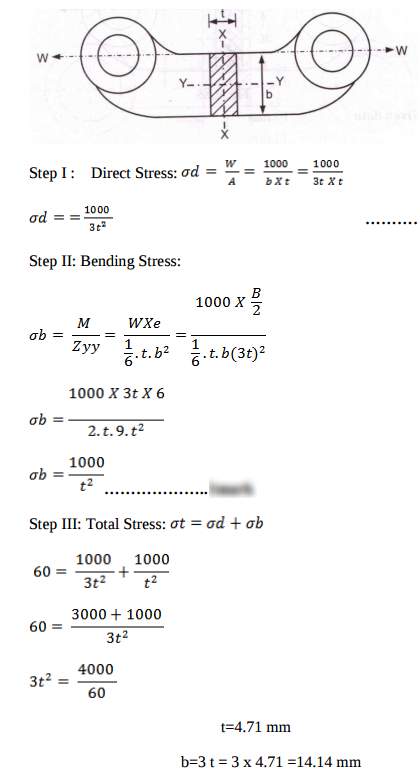

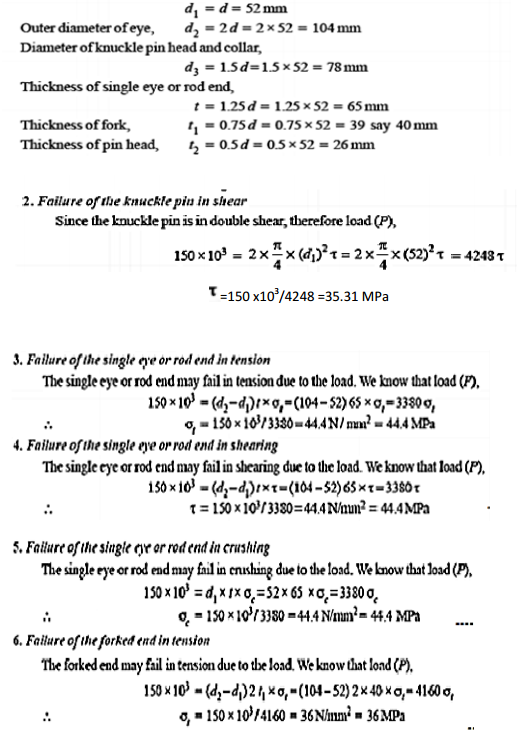

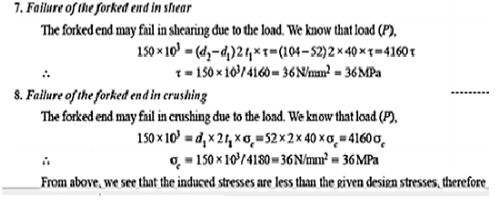

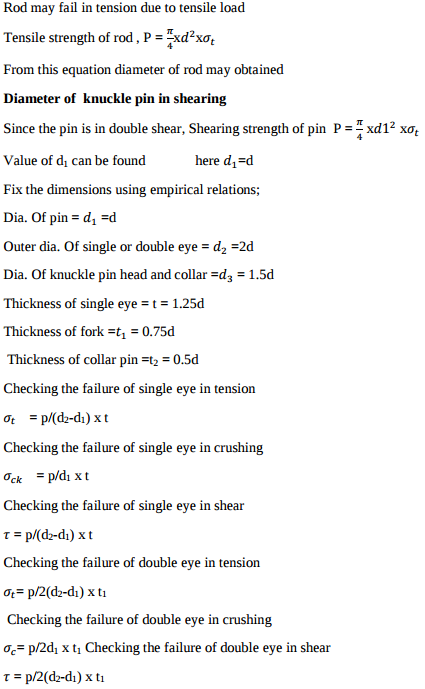

Question:

Design a knuckle joint to transmit 150 KN. The design stresses may be taken as 75 MPa in tension, 60 MPa in shear and 150 MPa in compression. Answer:

|

8 |

view |

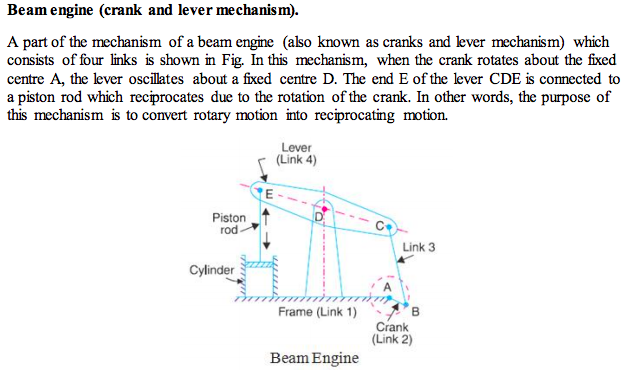

| Q 2 a ) |

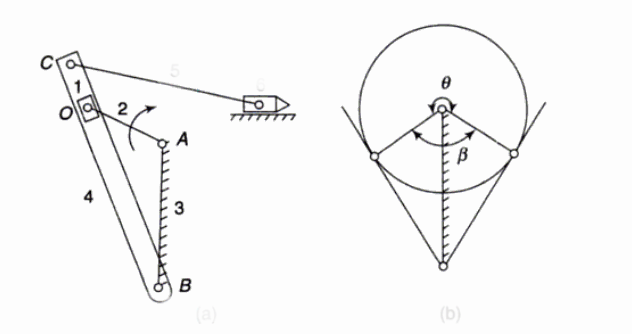

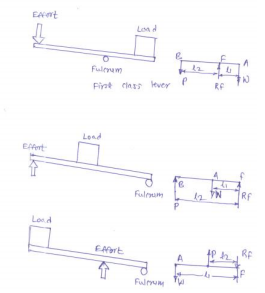

Question:

Draw a neat sketch and explain working of beam engine. Answer:

|

4 |

view |

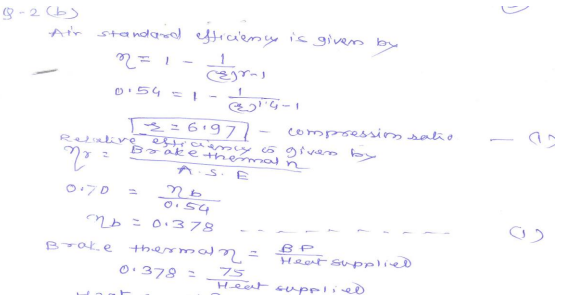

| Q 2 b ) |

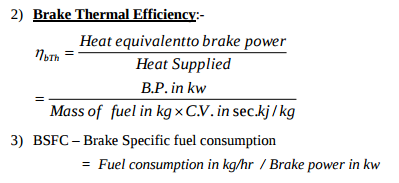

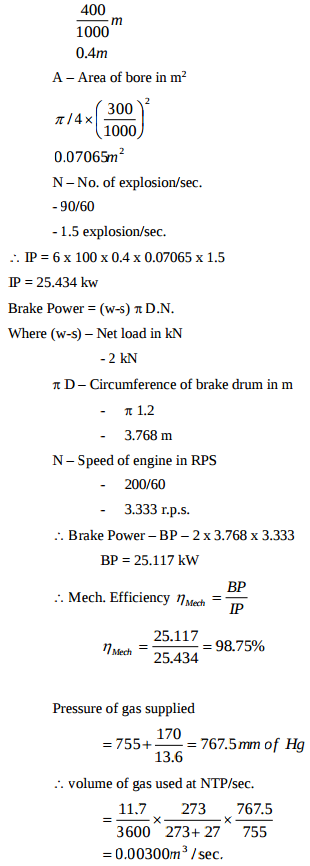

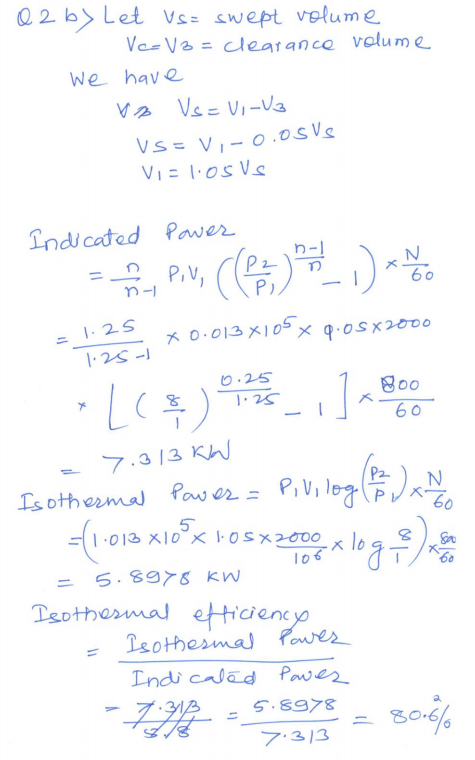

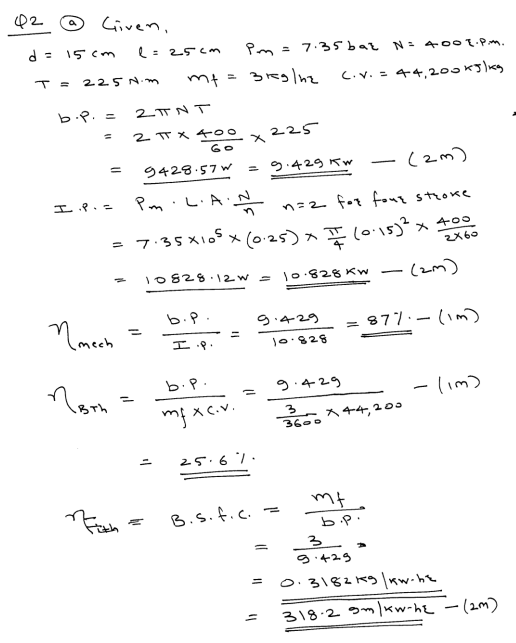

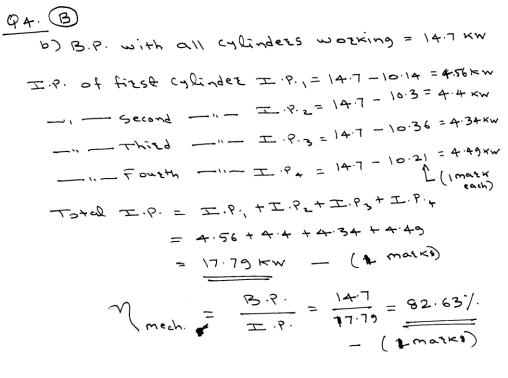

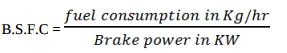

Question:

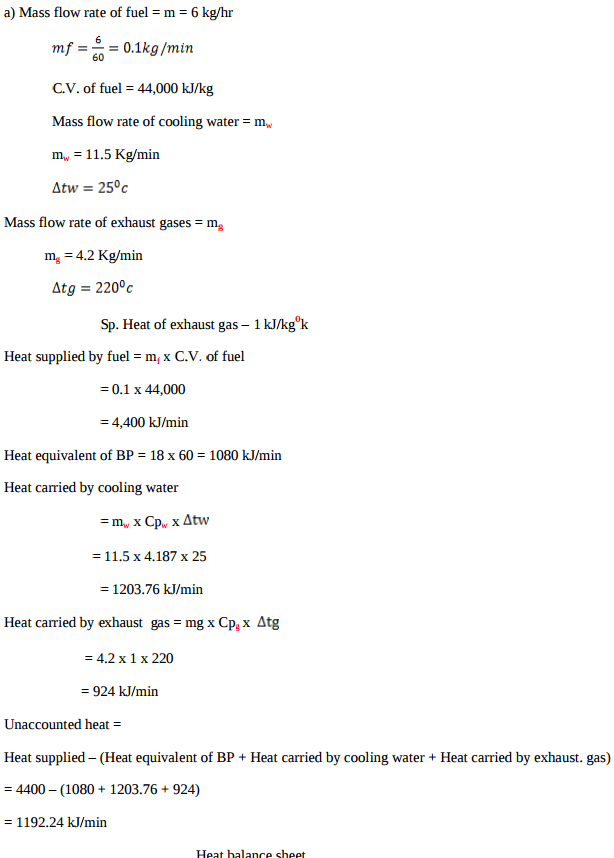

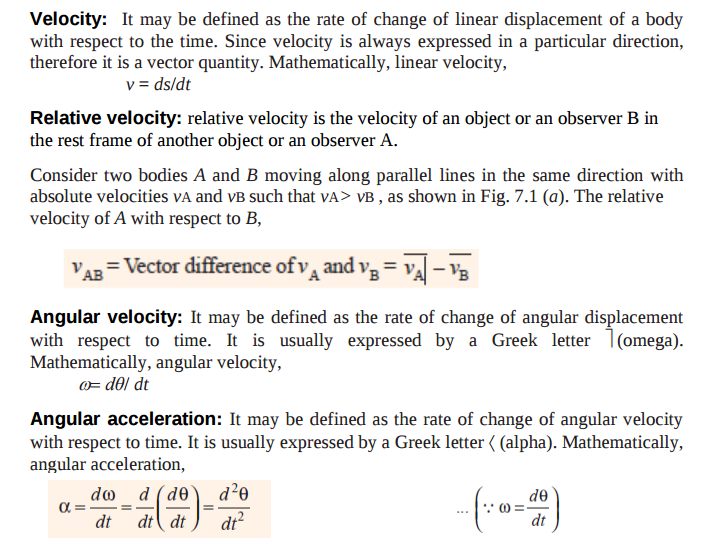

The following data refers to a trial conducted on 4-stroke petrol engine Answer:

|

8 |

view |

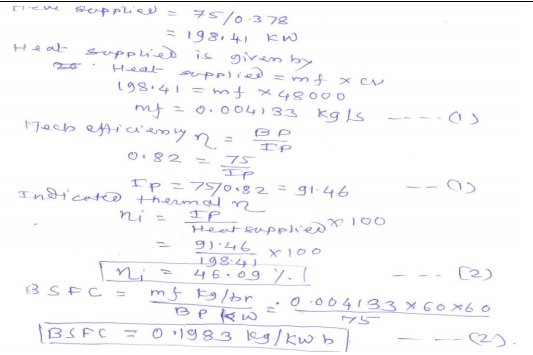

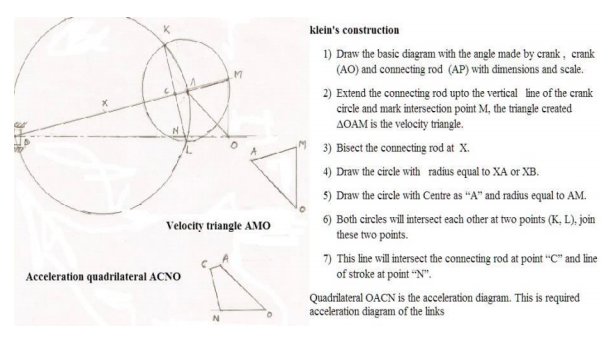

| Q 2 b ) |

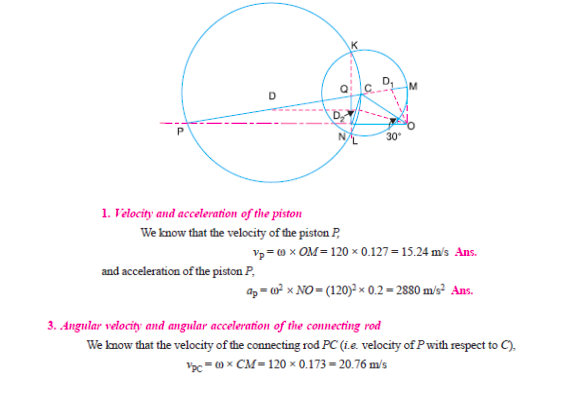

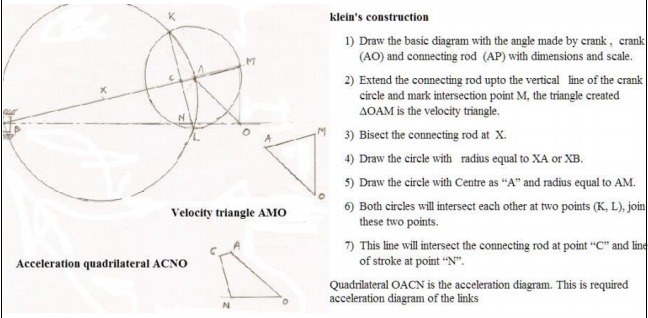

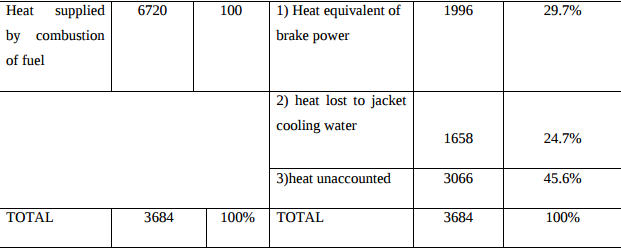

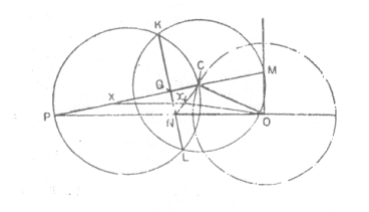

Question:

Explain with neat sketch how to find the velocity of a slider in slider crank mechanism by Klein’s construction. Answer:

|

2 |

view |

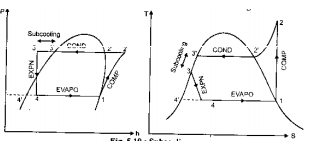

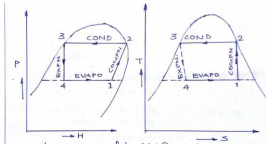

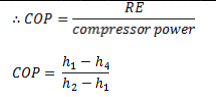

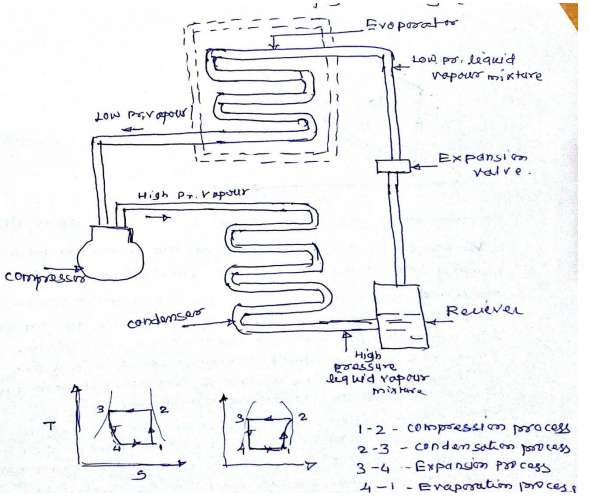

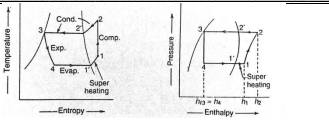

| Q 2 b ) |

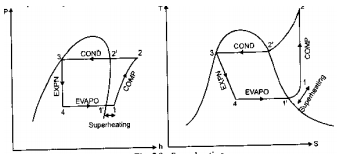

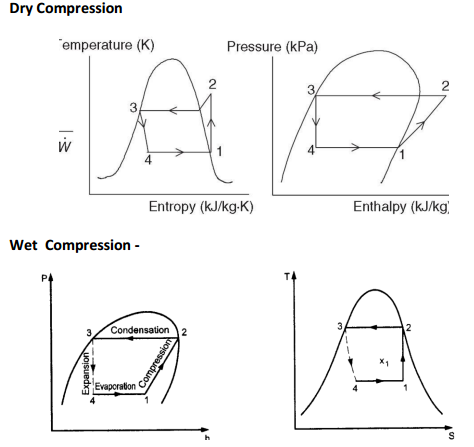

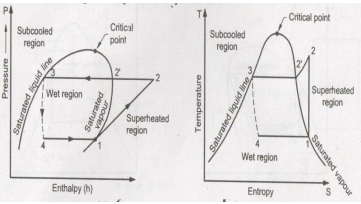

Question:

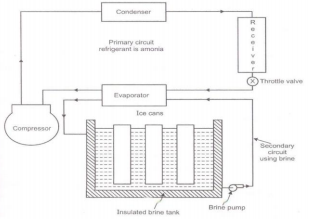

Explain vapour compression refrigeration cycle on T-S and p-h charts (for superheated vapourat the end of compression) Answer:

|

8 |

view |

| Q 2b)(ii) |

Question:

Draw neat sketch of a protected type flanged coupling showing all details. Answer:

|

8 |

view |

| Q 2b)(l) |

Question:

(i) State and explain two most important reasons for adopting involute curves for a gear tooth profile Answer:

|

8 |

view |

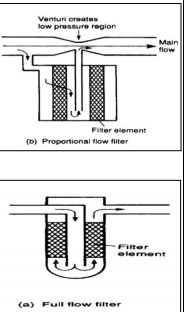

| Q 2 c ) |

Question:

What is function of filters ? Classify the filters and draw any two types of filters Answer:

|

8 |

view |

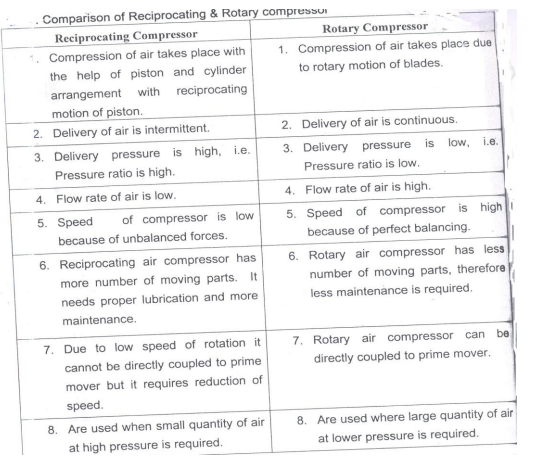

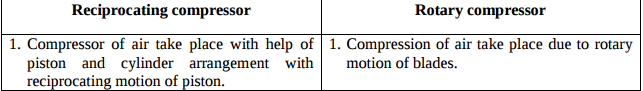

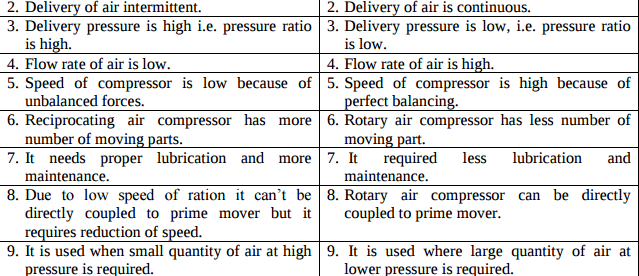

| Q 2 c ) |

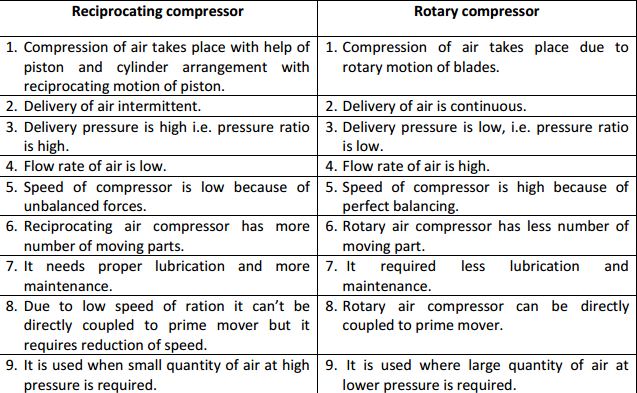

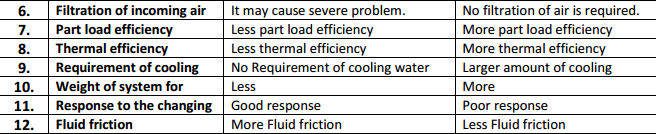

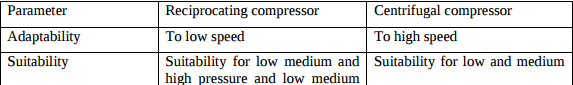

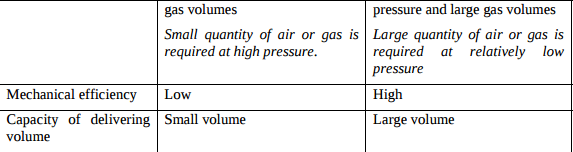

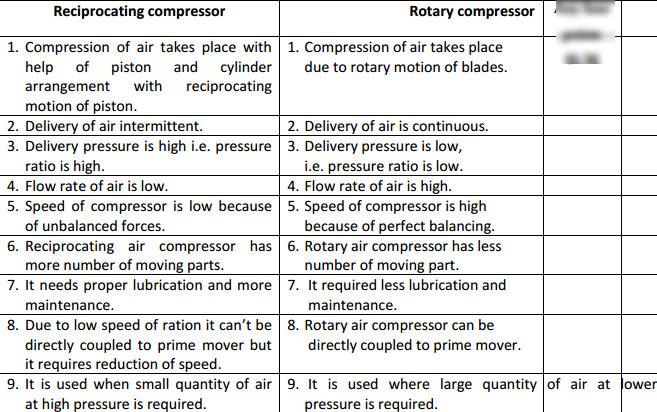

Question:

Differentiate between reciprocating air compressor and rotary air compressor......... Answer:

|

8 |

view |

| Q 2 c ) |

Question:

Draw and explain in short, types of followers used in cam and follower. Answer:

|

4 |

view |

| Q 2c)(i) |

Question:

Why are bushes of softer material inserted in the eyes of levers? Answer:

|

8 |

view |

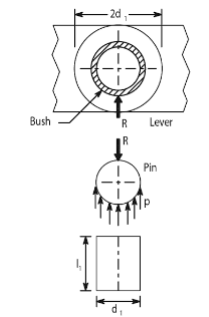

| Q 2c)(ii) |

Question:

Explain the following types of stresses Answer:

|

8 |

view |

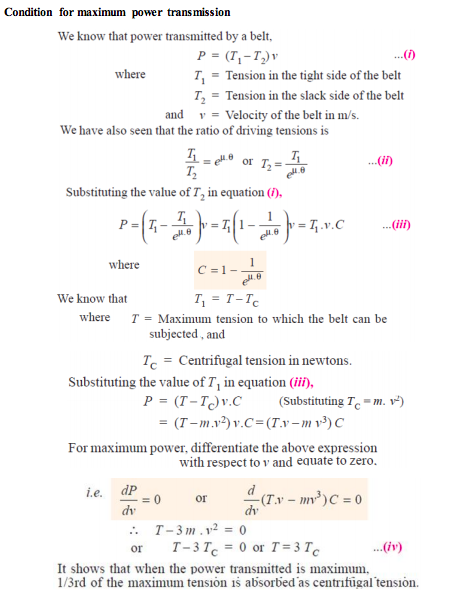

| Q 2 d ) |

Question:

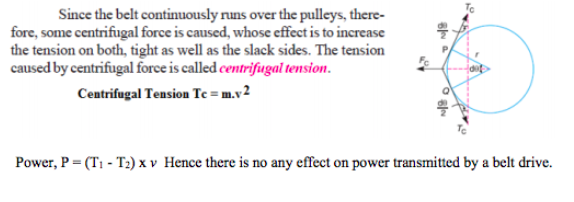

Explain condition for maximum power transmission. Answer:

|

4 |

view |

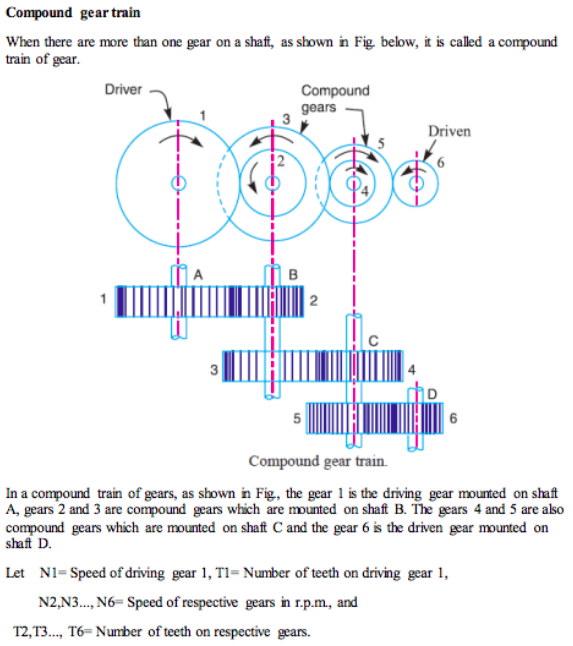

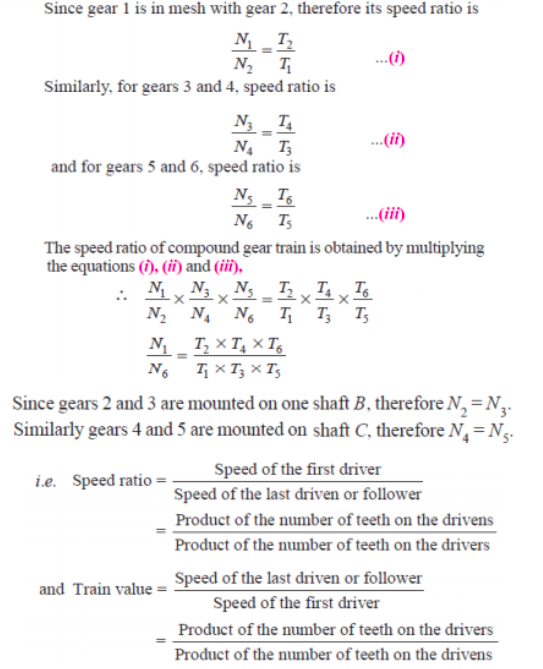

| Q 2 e ) |

Question:

Explain the compound gear train with neat sketch and write down the velocity ratio’s equation. Answer:

|

4 |

view |

| Q 2 f ) |

Question:

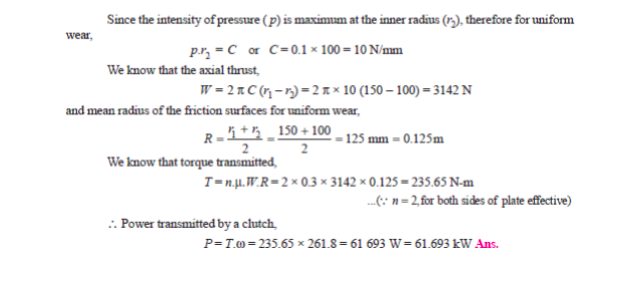

A multiplate clutch has three pairs of contact surfaces. The outer and inner radii of the contact surfaces are 100 mm and 50 mm respectively. The maximum axial spring force is limited to 1.25 kN. If the co-efficient of friction is 0.35 and assuming uniform wear, find the power transmitted by the clutch at 1600 rpm. Answer: |

4 |

view |

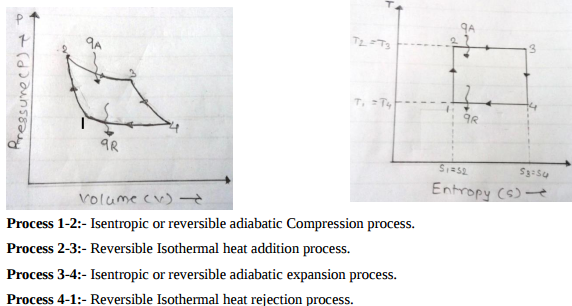

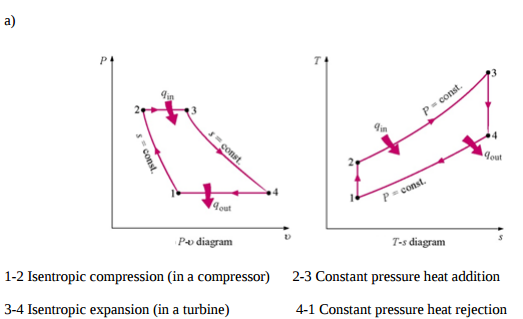

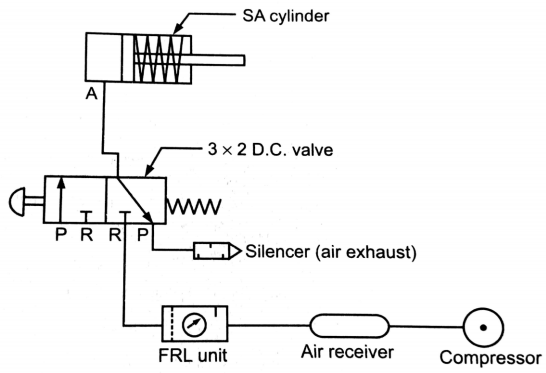

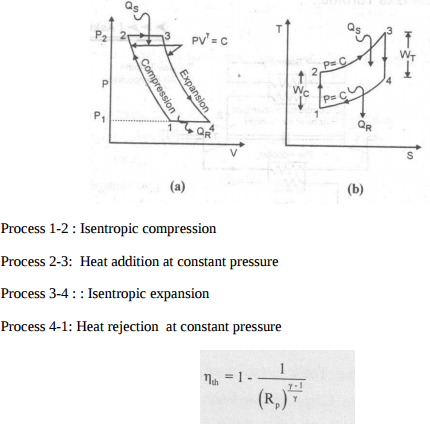

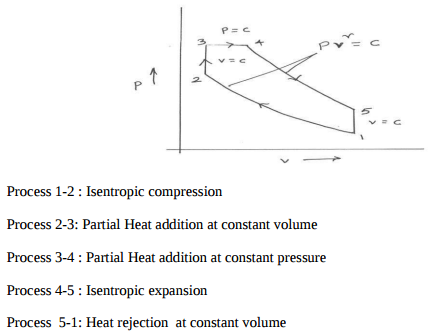

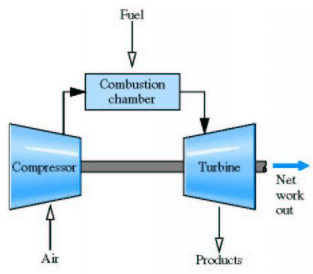

| Q 3 ) |

Question:

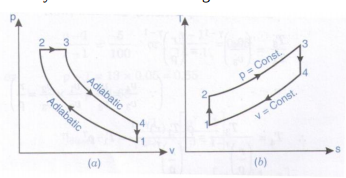

Represent Brayton cycle on PV and TS diagram. Name the processes completing the cycle Answer:

|

4 |

view |

| Q 3 a ) |

Question:

Differentiate between mechanism and machine. Answer:

|

4 |

view |

| Q 3 a ) |

Question:

Explain 4-way-3 position direction control valve used in hydraulic system. Answer:

|

4 |

view |

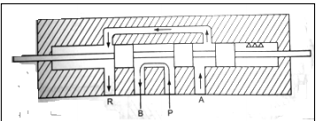

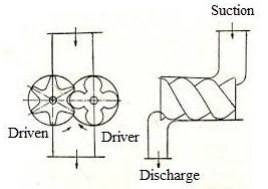

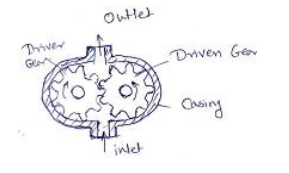

| Q 3 b ) |

Question:

Explain gear pump with neat sketch. Answer:

|

4 |

view |

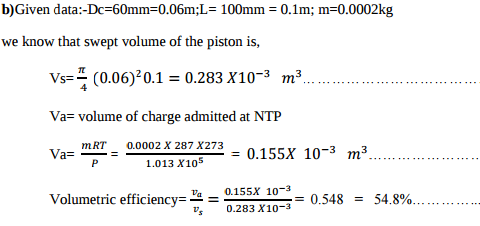

| Q 3 b ) |

Question:

A petrol engine has a cylinder of diameter 60 mm and stroke 100 mm. If the mass of charge Answer:

|

4 |

view |

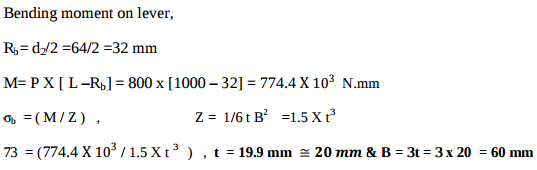

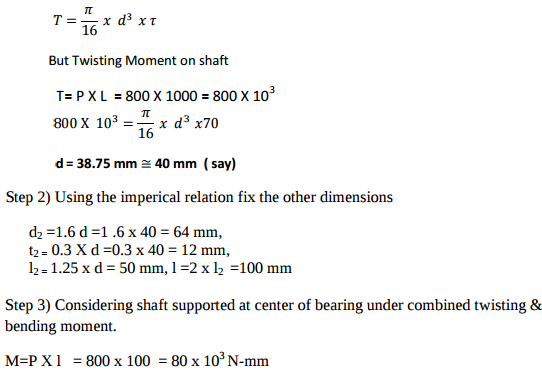

| Q 3 b ) |

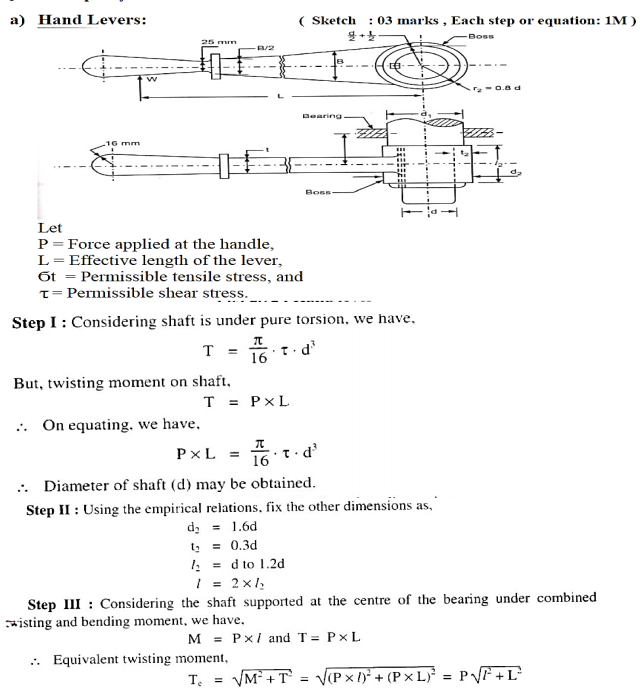

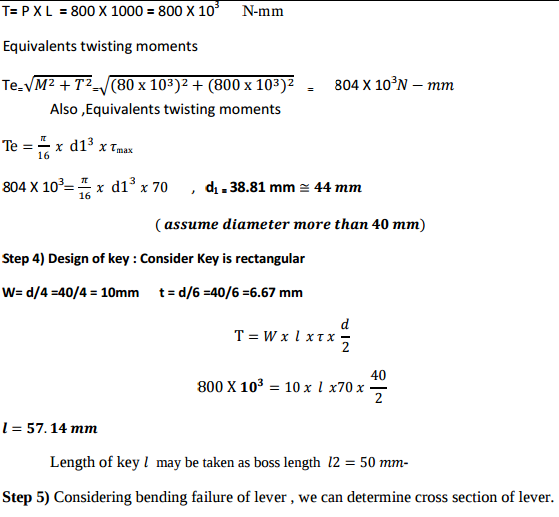

Question:

Design a foot brake lever from the following data: Length of lever from C.G. of the spindle to the point of application of the load = 1 meter. Max. load on the foot plate = 800 N Overhang from the nearest bearing = 100 mm Permissible tensile and shear stress = 70 MPa. Answer:

|

4 |

view |

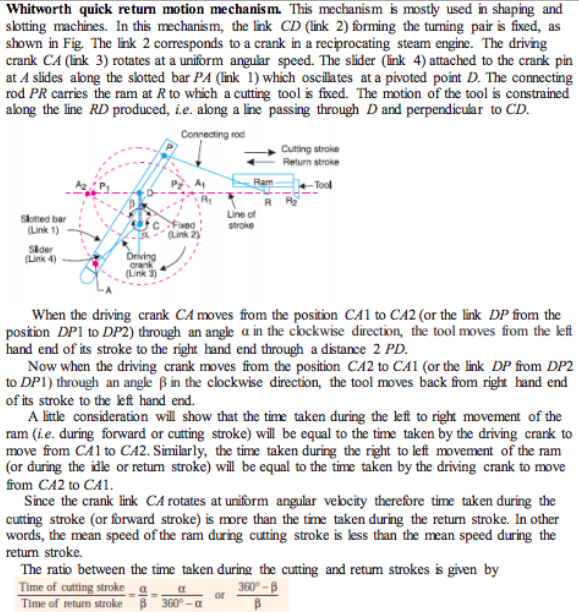

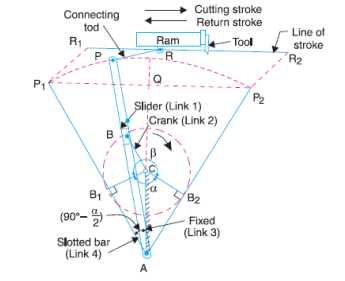

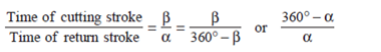

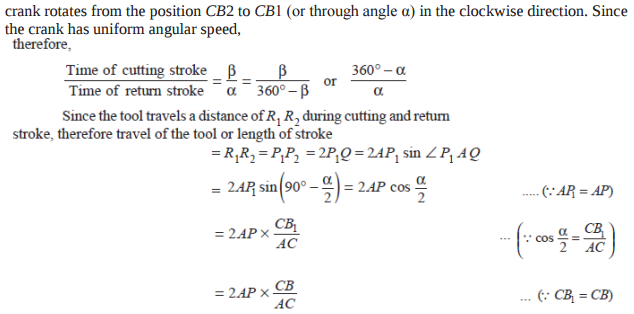

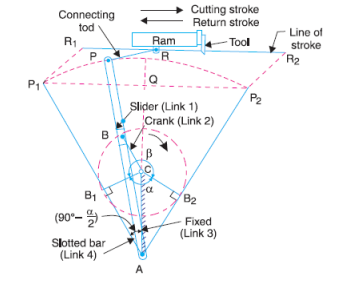

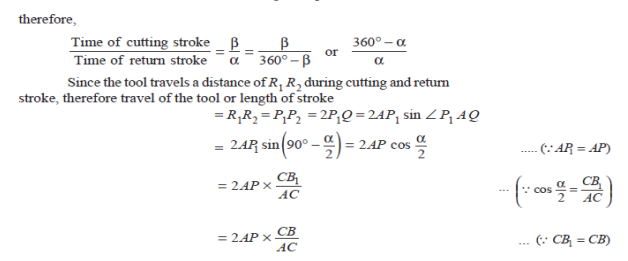

| Q 3 b ) |

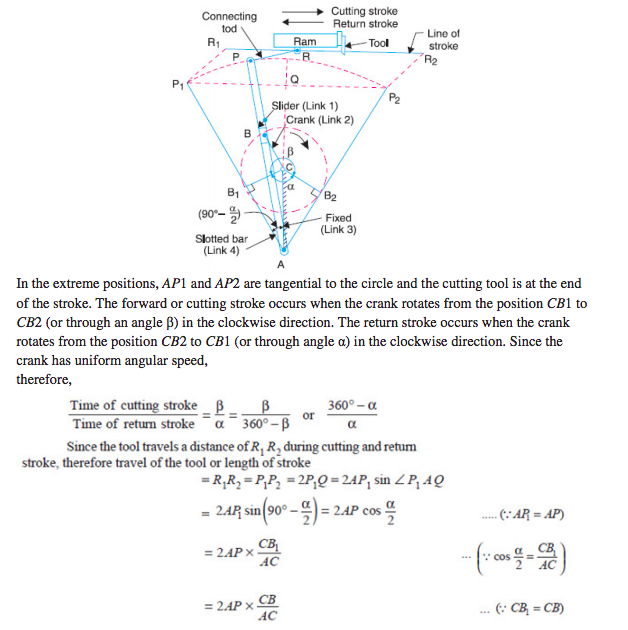

Question:

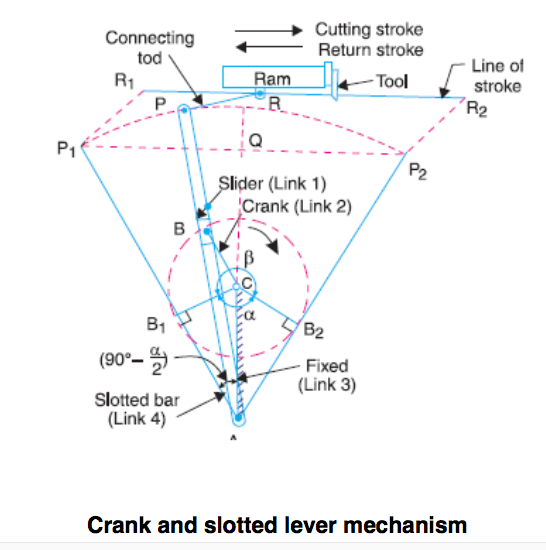

Explain the working of Whitworth quick return mechanism. Answer:

|

4 |

view |

| Q 3 c ) |

Question:

Explain any four criteria for selection of hydraulic pump in hydraulic system. Answer:

|

4 |

view |

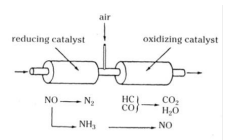

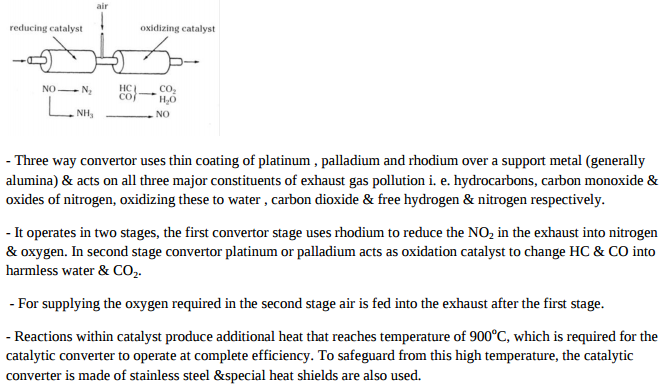

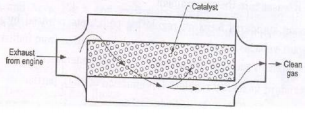

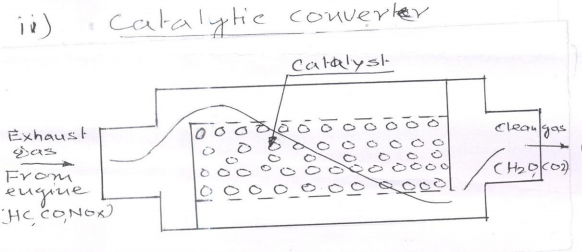

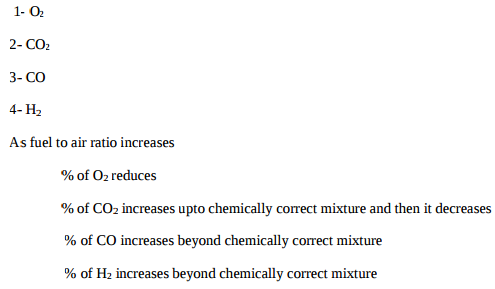

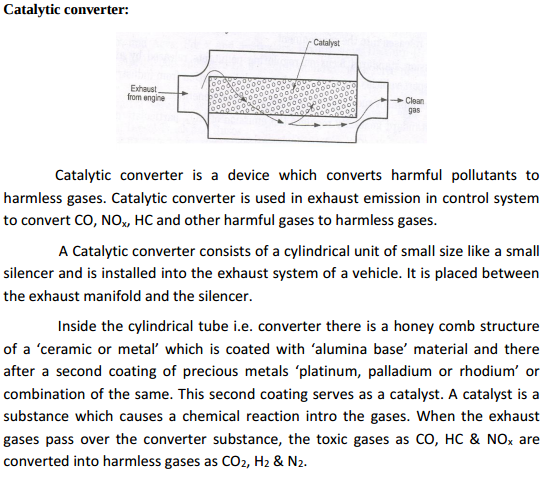

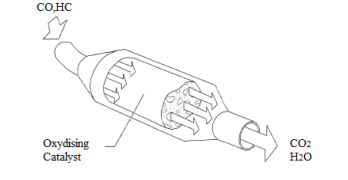

| Q 3 c ) |

Question:

Explain with neat sketch two way catalytic converter. Answer:

|

4 |

view |

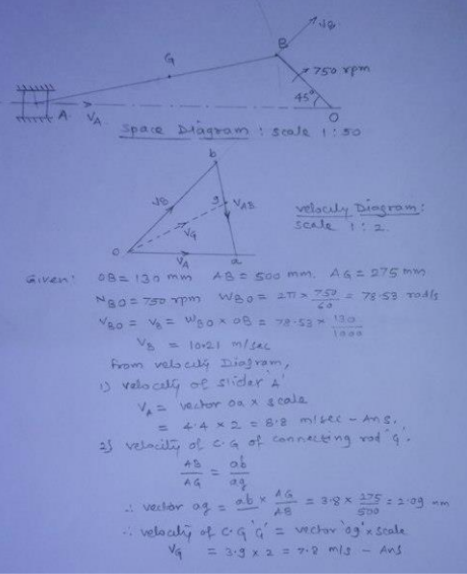

| Q 3 c ) |

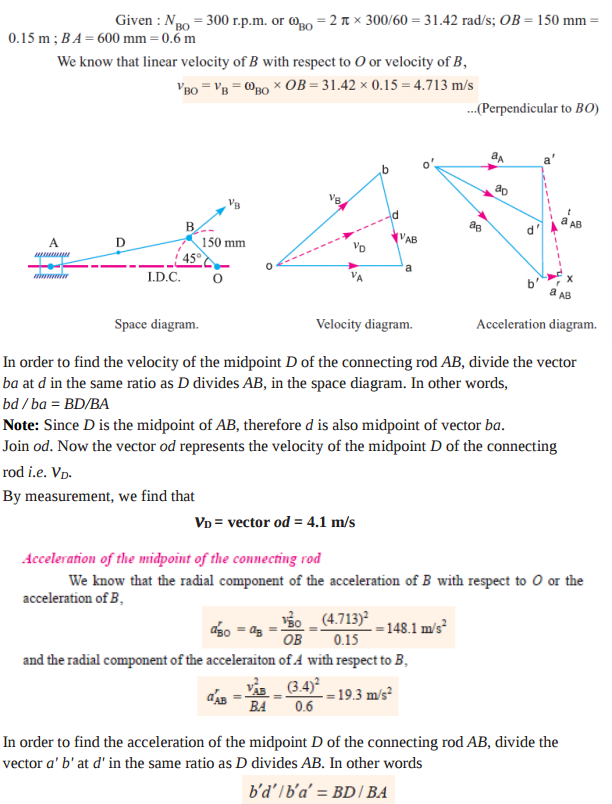

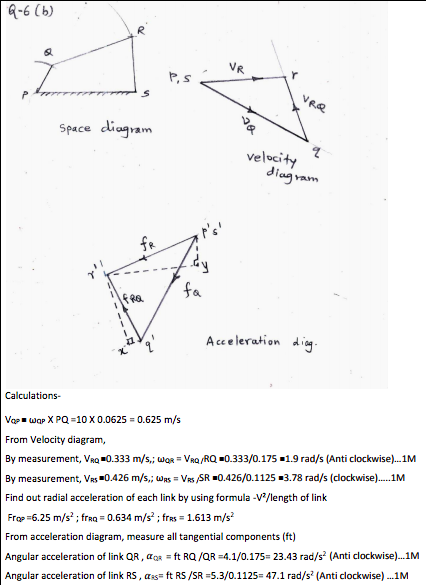

Question:

In slider crank mechanism, the length of crank OB and connecting rod AB are 130 mm and 500 mm respectively. The centre of gravity G of the connecting rod is 275 mm from slider A. The crank speed is 750 rpm in clockwise. When crank has turned 45 from inner dead centre position determine (i) velocity of slider ‘A’ (ii) velocity of centre of gravity of connecting rod ‘G’. Answer:

|

4 |

view |

| Q 3 d ) |

Question:

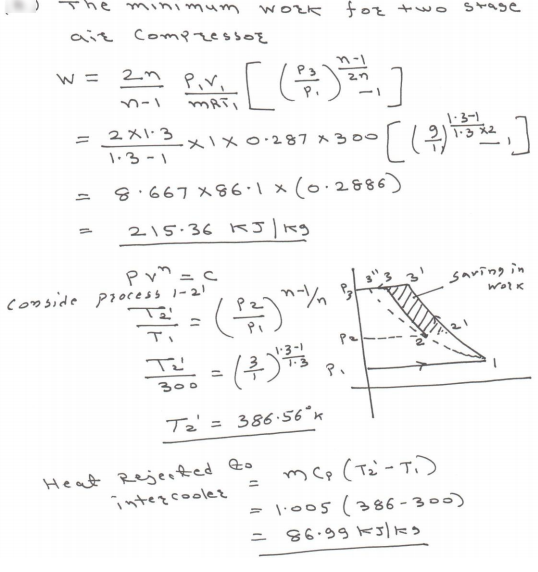

Name any four components of pneumatic system. What are the factors considered while selecting them ? Answer:

|

4 |

view |

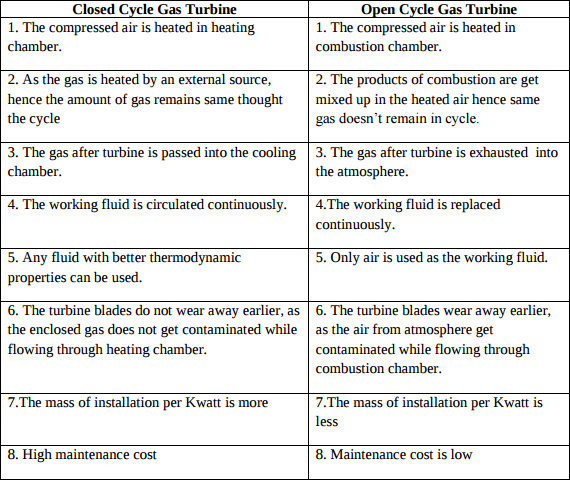

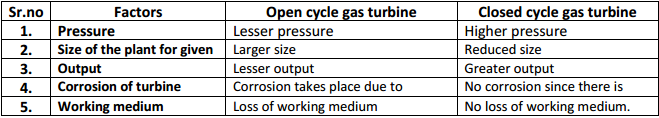

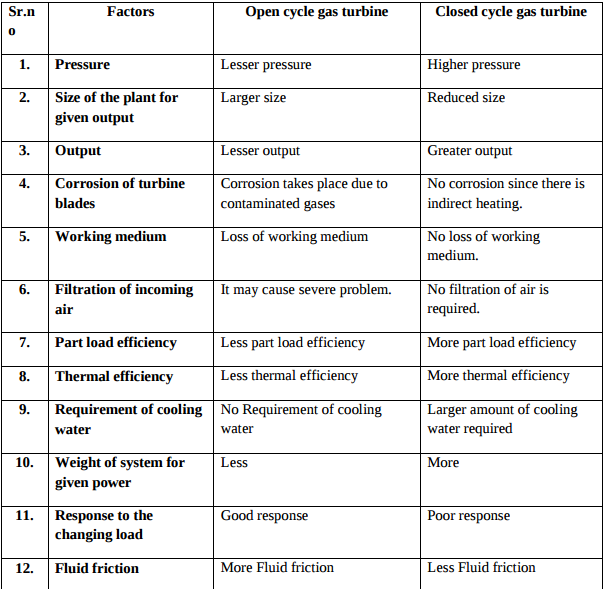

| Q 3 d ) |

Question:

Differentiate between closed cycle and open cycle gas turbine Answer:

|

4 |

view |

| Q 3 d ) |

Question:

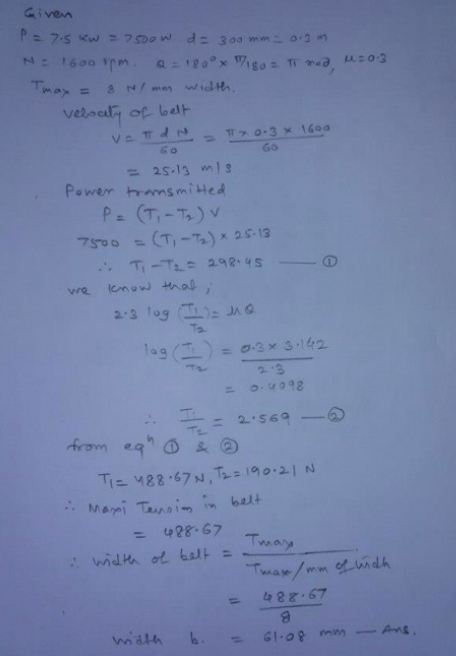

Find the width of the belt, necessary to transmit 7.5 kW to a pulley 300 mm diameter, if the pulley makes 1600 rpm and the co-efficient of friction between the belt and pulley is 0.3. Assume the angle of contact as 180o and the maximum tension in the belt is not to exceed 8 N/mm width. Answer:

|

4 |

view |

| Q 3 d ) |

Question:

Compare welded joints with screwed joints. (Any six points) Answer:

|

4 |

view |

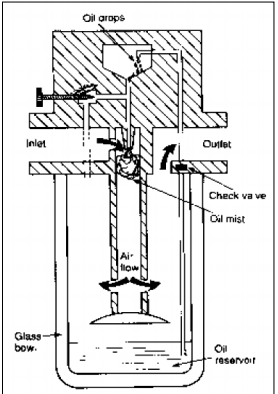

| Q 3 e ) |

Question:

Draw labelled sketch of air lubricator. Answer:

|

4 |

view |

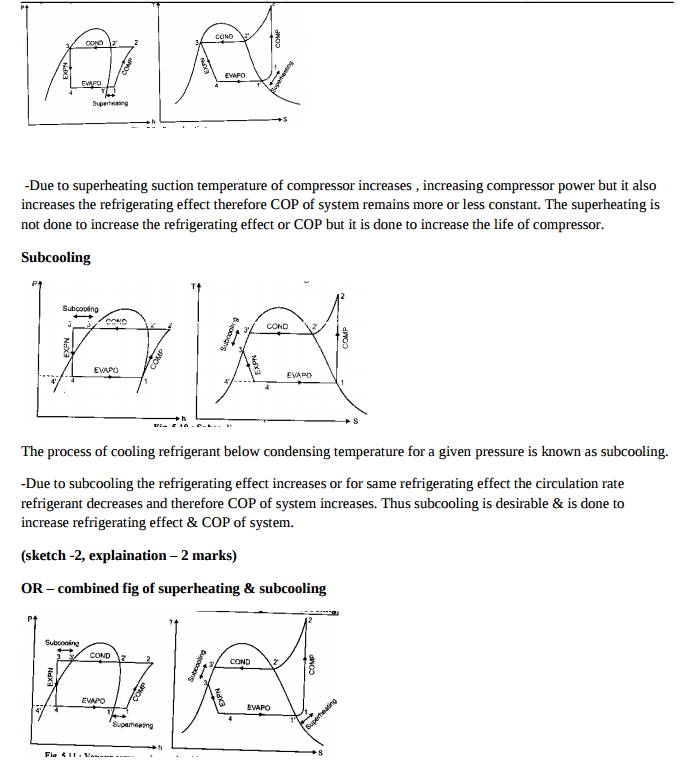

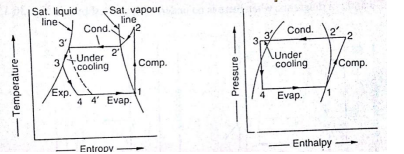

| Q 3 e ) |

Question:

Explain the effect of superheating and subcooling on the performance of vapour compression cycle Answer:

|

4 |

view |

| Q 3 e ) |

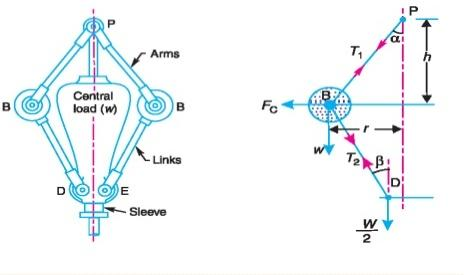

Question:

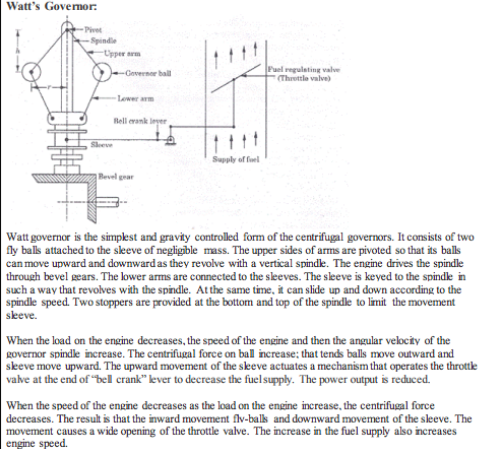

Explain the working of Watt governor with neat diagram. Answer:

|

4 |

view |

| Q 3 e ) |

Question:

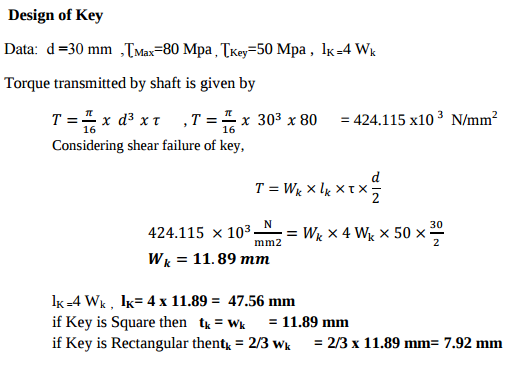

A shaft 30 mm. diameter is transmitting power at a maximum shear stress of 80 MPa. If a pulley is connected to the shaft by means of a key, find the dimension of the key so that stress in the key is not to exceed 50 MPa and length of the key is 4 times the width. Answer:

|

4 |

view |

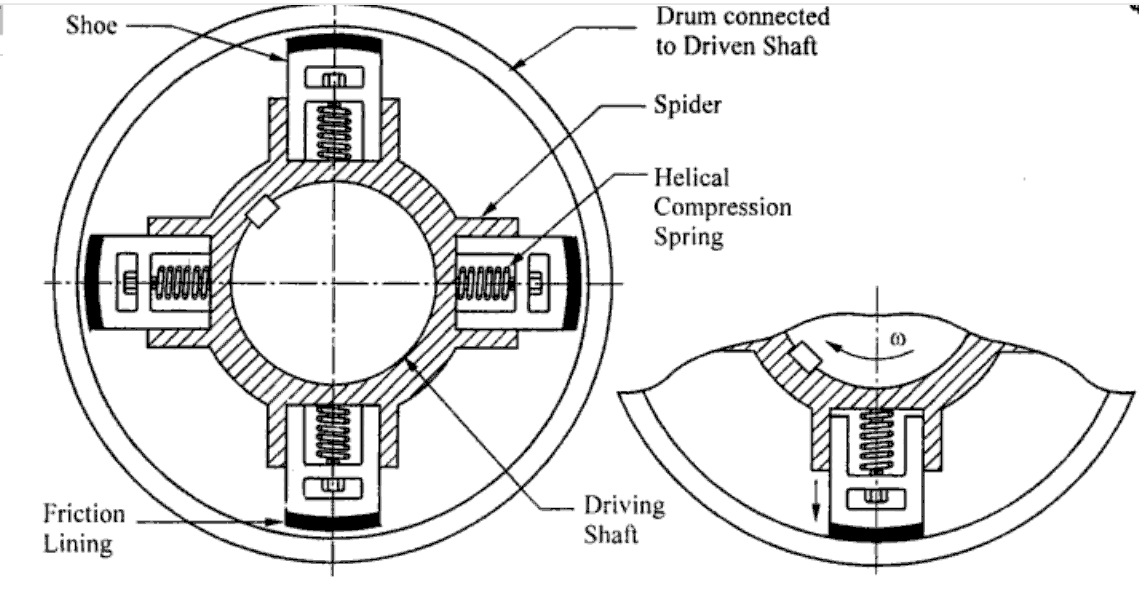

| Q 3 f ) |

Question:

Explain the working of centrifugal clutch with neat sketch. Answer:

|

4 |

view |

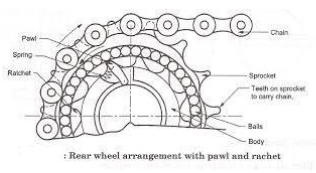

| Q 4 a ) |

Question:

Explain the working of freewheel mechanism of bicycle with sketch. Answer:

|

4 |

view |

| Q 4a)(a) |

Question:

a) Define : Answer:

|

6 |

view |

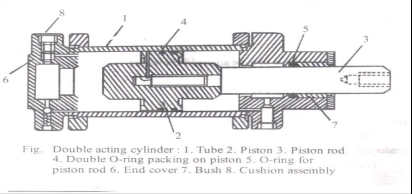

| Q 4a)(a) |

Question:

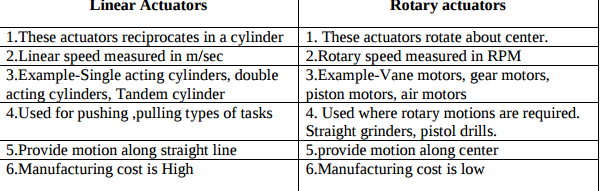

What are actuators ? Draw a double acting cylinder. Answer:

|

4 |

view |

| Q 4a)(b) |

Question:

Explain with sketch working of screw compressor. Answer:

|

4 |

view |

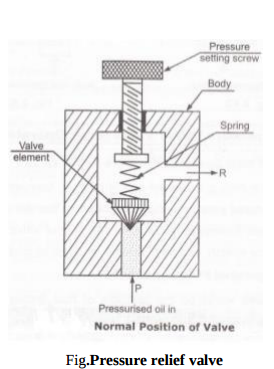

| Q 4a)(b) |

Question:

Explain pressure relief valve in pneumatic system. Answer:

|

4 |

view |

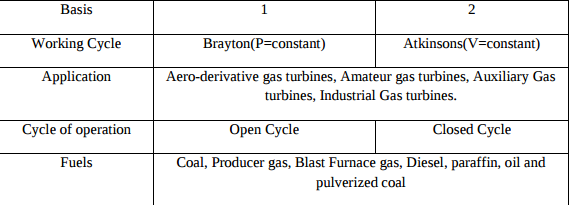

| Q 4a)(c) |

Question:

Classify gas turbines on the following basis : i) Working cycle ii) Application iii) Cycle of operation iv) Fuels Answer:

|

4 |

view |

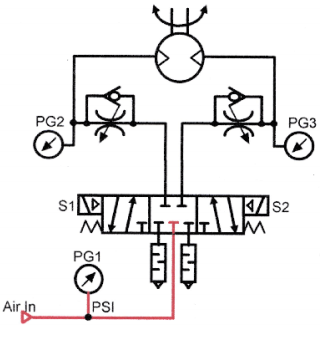

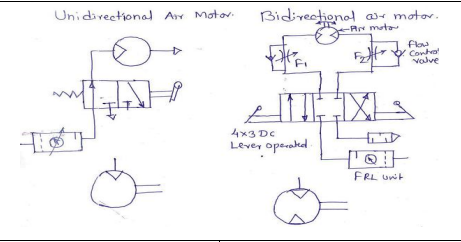

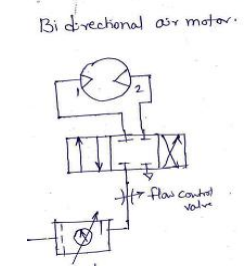

| Q 4a)(c) |

Question:

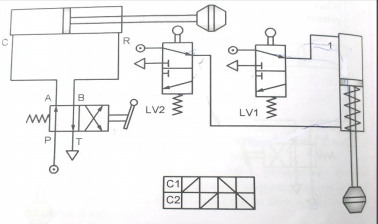

Explain with sketch, a pneumatic circuit for speed control of bidirectional motor. Answer:

|

4 |

view |

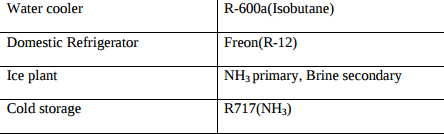

| Q 4a)(d) |

Question:

Name the refrigerants used for : i) Water cooler ii) Domestic refrigerator iii) Ice plant iv) Cold storage. Answer:

|

4 |

view |

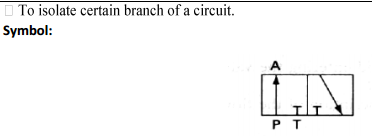

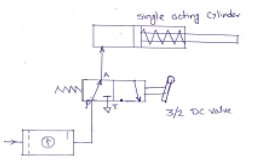

| Q 4a)(d) |

Question:

State any two applications of 3 × 2 DC valve. Draw symbol for the same. Answer:

|

4 |

view |

| Q 4a)(i) |

Question:

a) Attempt any THREE of the following: 12 (i) Give the composition of : 1) 35Mn 2 Mo28 2) 30Ni 4 Crl and 3) 25 Cr 3 Mo 55 Answer:

|

4 |

view |

| Q 4a)(ii) |

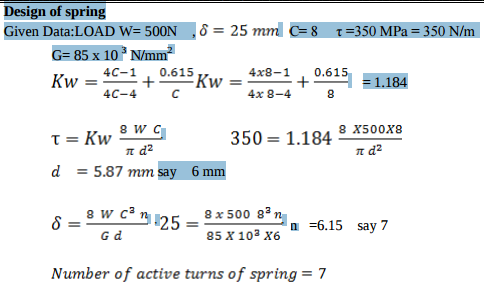

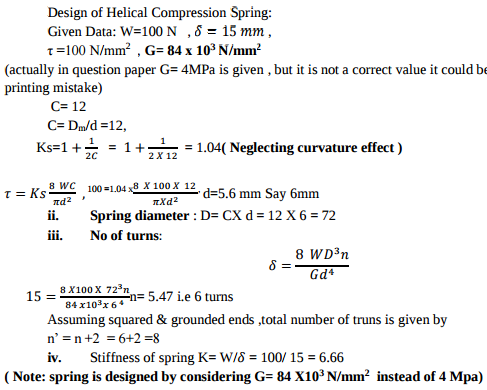

Question:

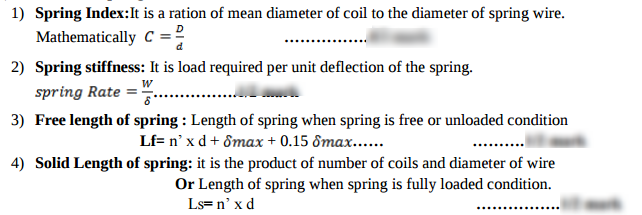

Define following terms with respect to springs : 1) Free length 2) Solid height 3) Spring rate 4) Spring index Answer:

|

4 |

view |

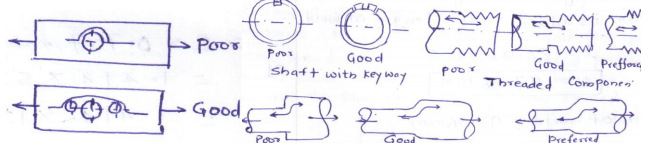

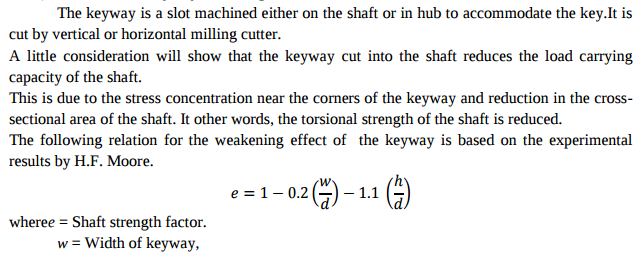

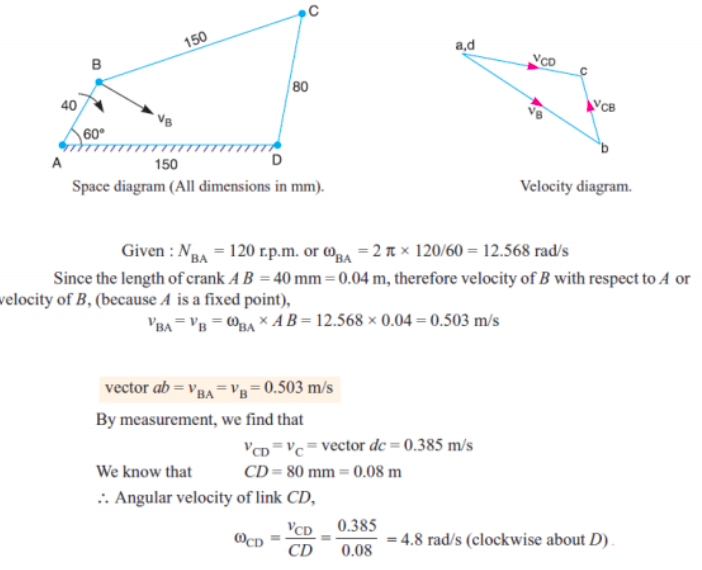

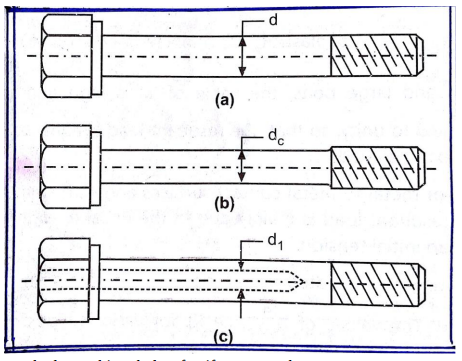

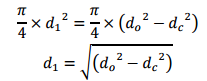

| Q 4a)(iii) |

Question:

Explain effect of keyways on strength of shaft. Name one type of key which does not affect strength of shaft Answer:

|

4 |

view |

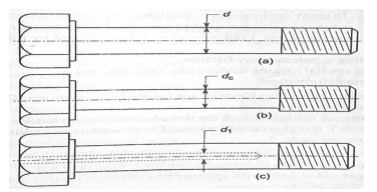

| Q 4a)(iv) |

Question:

Define following terms w.r.t. bolts: 1) Major diameter 2) Minor diameter 3) Pitch 4) Lead Answer:

|

4 |

view |

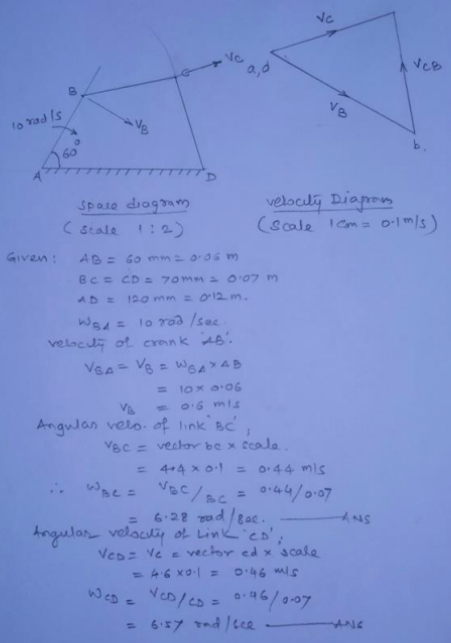

| Q 4 b ) |

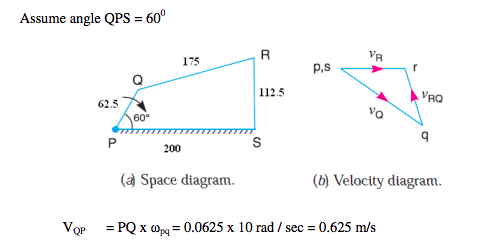

Question:

In a four bar mechanism ABCD link AD is fixed and the crank AB rotates at 10 radians per second in clockwise, lengths of the links are AB = 60 mm, BC = CD = 70 mm, DA = 120 mm, when angle DAB = 60 and both B and C lie on the same side of AB, find angular velocities of BC and CD link. Answer:

|

4 |

view |

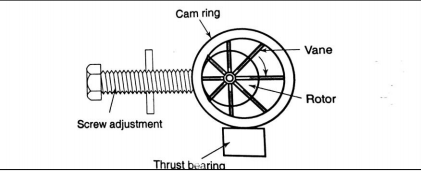

| Q 4b)(a) |

Question:

Explain with neat sketch the working of variable displacement vane pump. Answer:

|

6 |

view |

| Q 4b)(b) |

Question:

Compare pressure relief valve and pressure reducing valve. Answer: |

6 |

view |

| Q 4b)(i) |

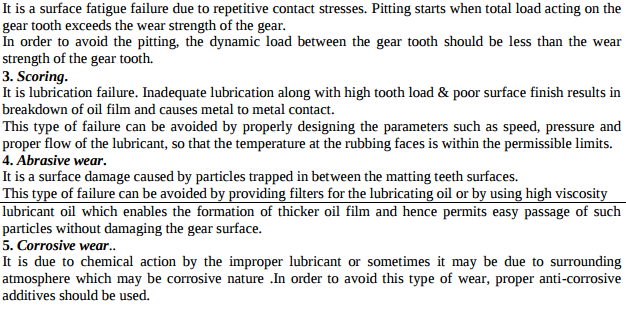

Question:

(i) Explain different causes of gear tooth failure and suggest possible remedies to avoid such failures Answer:

|

6 |

view |

| Q 4b)(ii) |

Question:

Explain the importance of Aesthetic considerations in design by giving any two examples. Answer:

|

6 |

view |

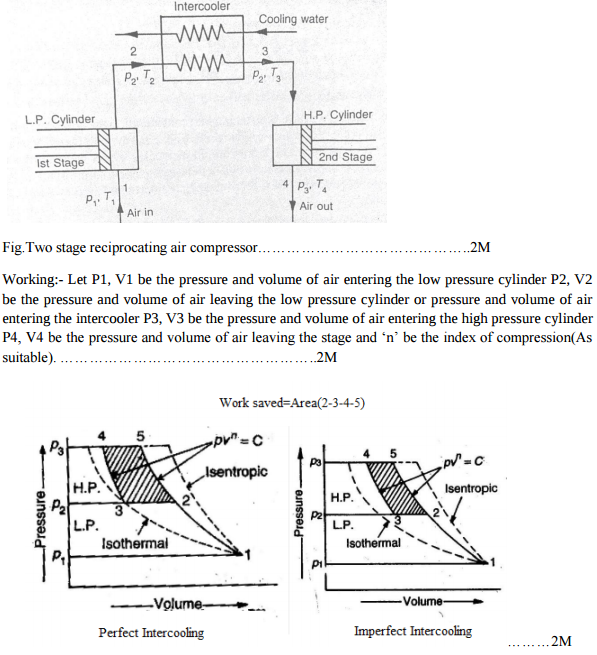

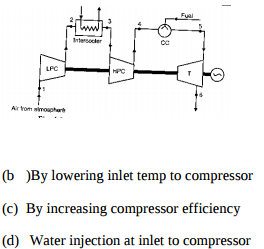

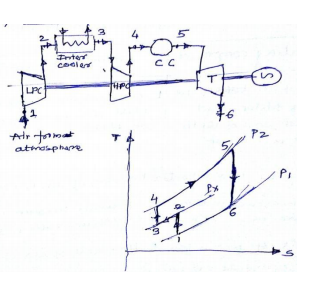

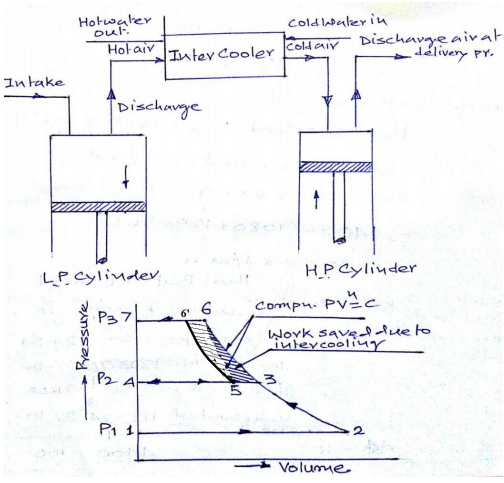

| Q 4b)(ii) |

Question:

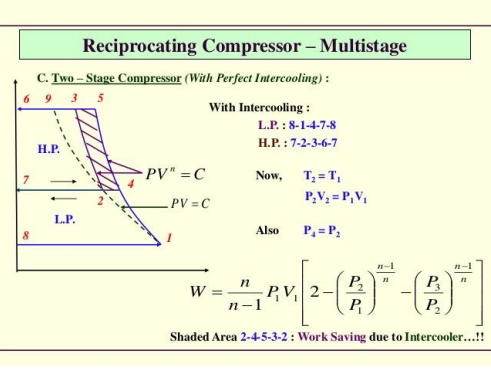

Explain the working of two stage reciprocating compressor. Show work saved on PV diagram. Answer:

|

6 |

view |

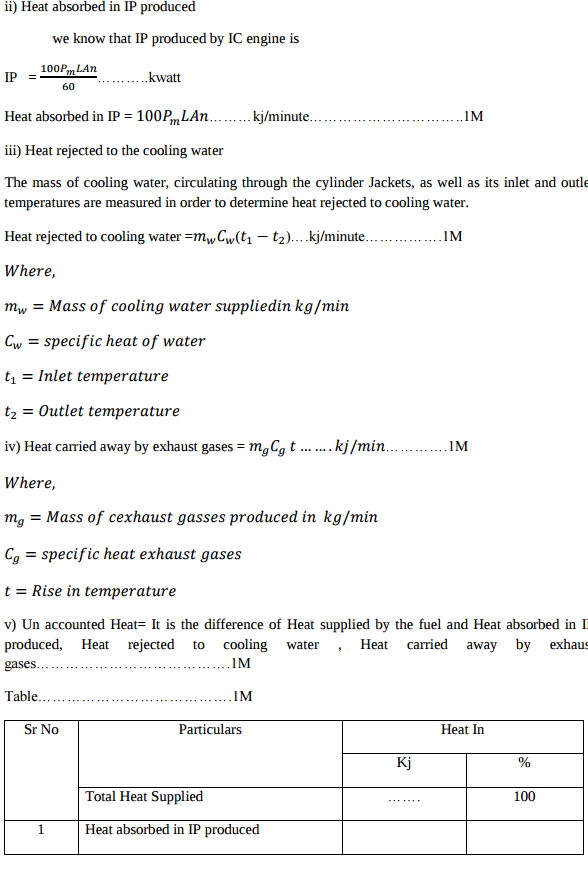

| Q 4b)(l) |

Question:

Explain how the heat balance sheet for an IC engine is prepared ? Answer:

|

6 |

view |

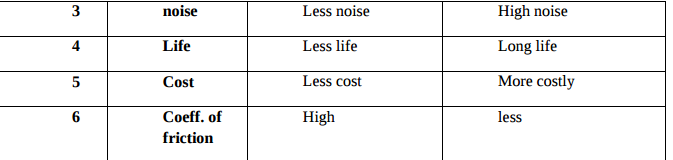

| Q 4 c ) |

Question:

What are the advantages of ‘V’ belt drive over flat belt drive ? Answer:

|

4 |

view |

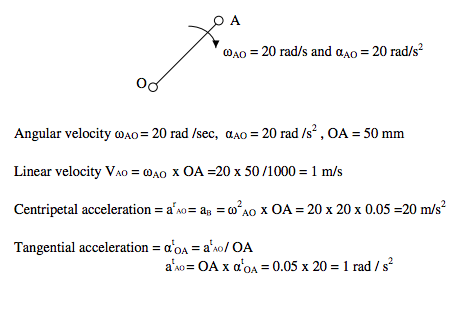

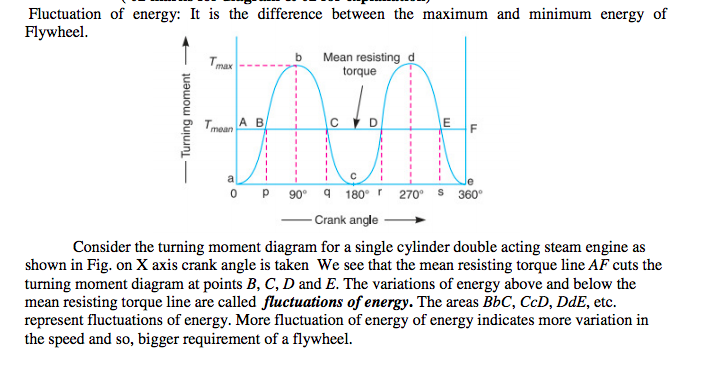

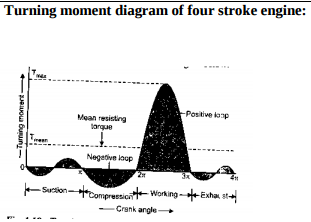

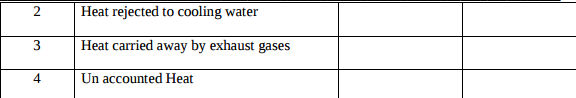

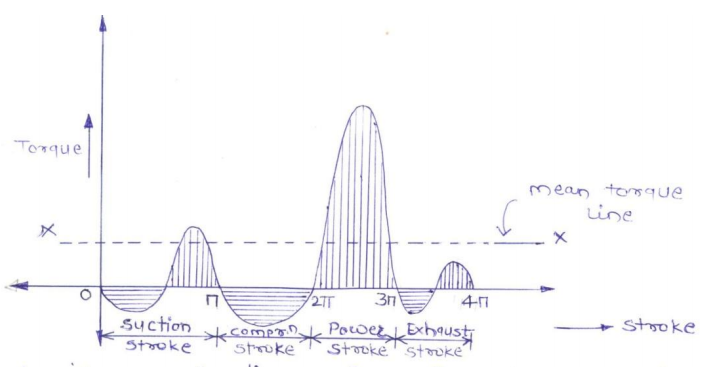

| Q 4 d ) |

Question:

Explain the working of flywheel with the help of turning moment diagram. Answer:

|

4 |

view |

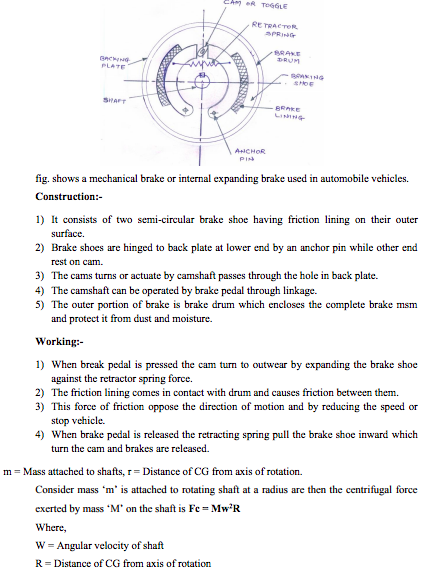

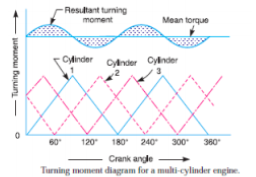

| Q 4 e ) |

Question:

Explain the working of internal expanding brake with neat sketch. Answer:

|

4 |

view |

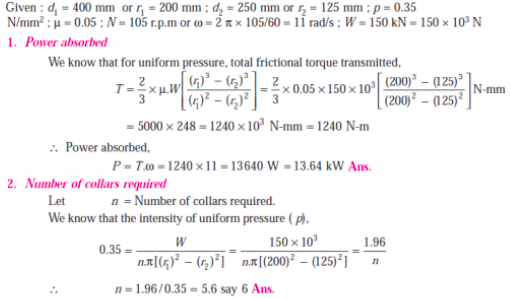

| Q 4 f ) |

Question:

A shaft has number of collars integral with it. The external diameter of the collars is 400 mm and the shaft diameter is 250 mm. If the uniform intensity of pressure is 0.35 N/mm2 and its co-efficient of friction is 0.05; find (i) power absorbed in overcoming friction when shaft rotates at 105 rpm and carries a load of 150 kN, and (ii) number of collars required. Answer:

|

4 |

view |

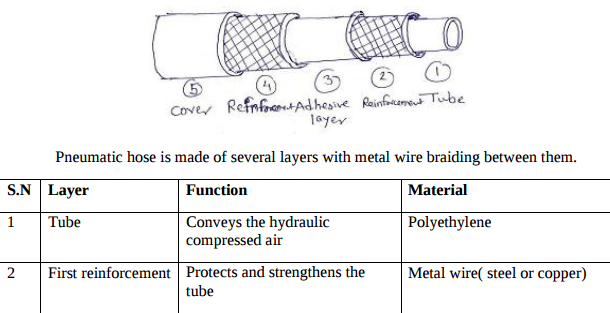

| Q 5 a ) |

Question:

List the factors to be considered for selecting the pipe while designing the pneumatic system. Give specification of pipes for the pneumatic system. Answer:

|

8 |

view |

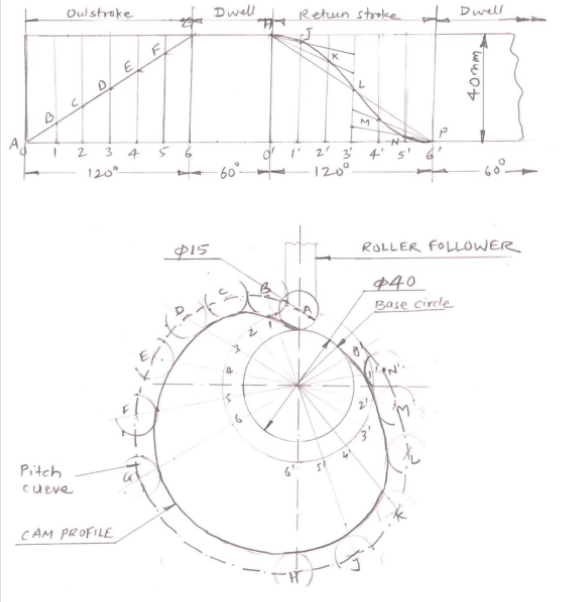

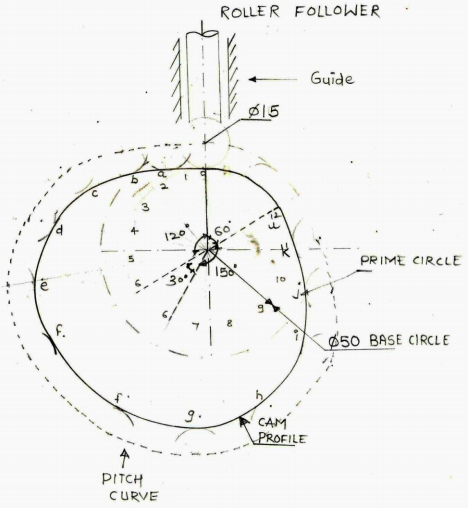

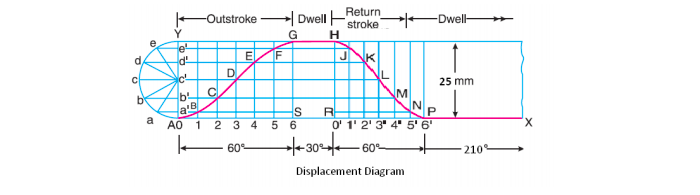

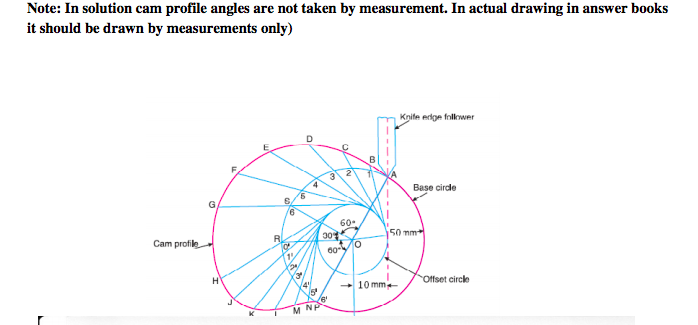

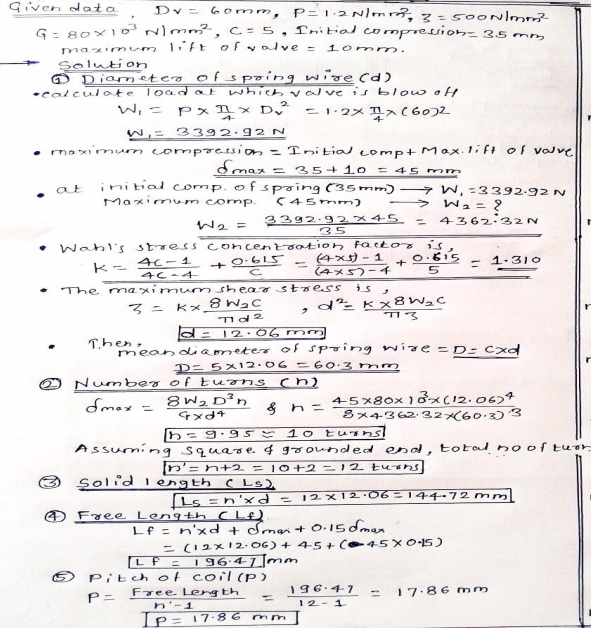

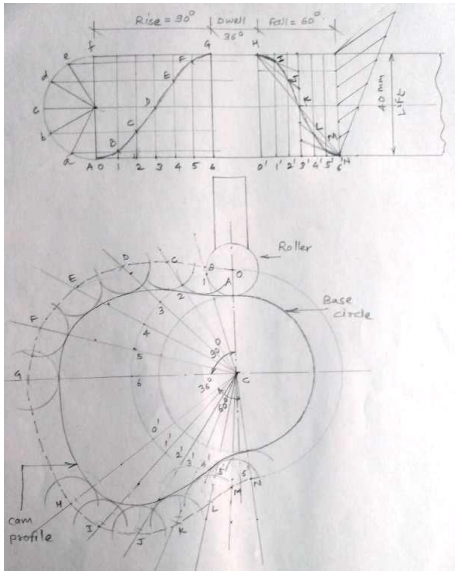

| Q 5 a ) |

Question:

A cam with 40 mm minimum diameter rotates in clockwise at uniform speed and has to give the following motion to a roller follower 15 mm diameter : (i) Follower to complete outward stroke of 40 mm during 120o of cam rotation with uniform velocity. (ii) Follower to dwell for 60o of cam rotation. (iii) Follower will return to its initial position during 120 of cam rotation with uniform acceleration and retardation. (iv) Follower will dwell for remaining 60o of cam rotation. Draw the profile of cam, if the axis of follower passes through the axis of cam. Answer:

|

8 |

view |

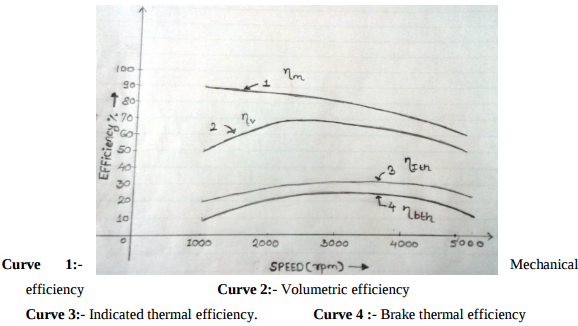

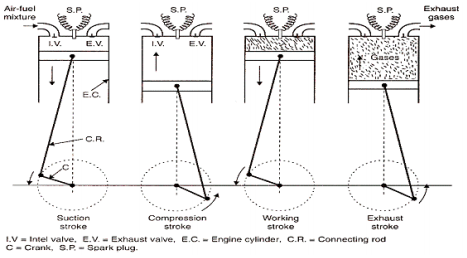

| Q 5 a ) |

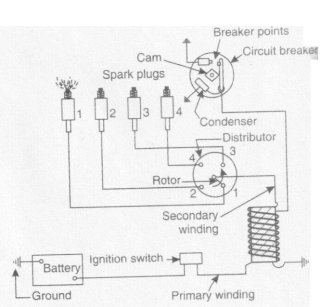

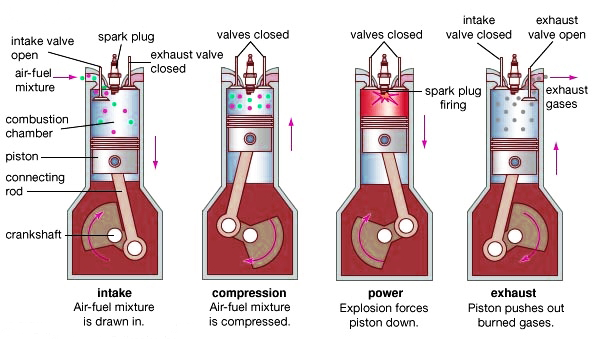

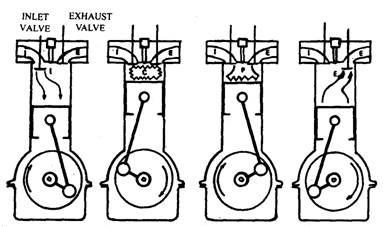

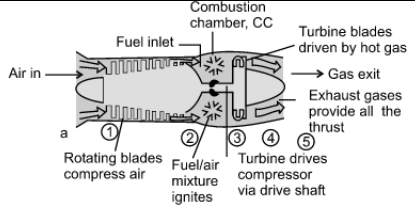

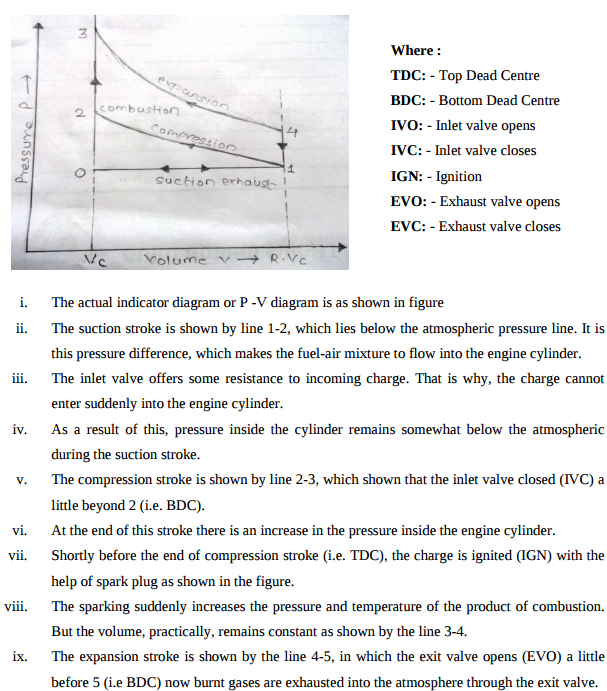

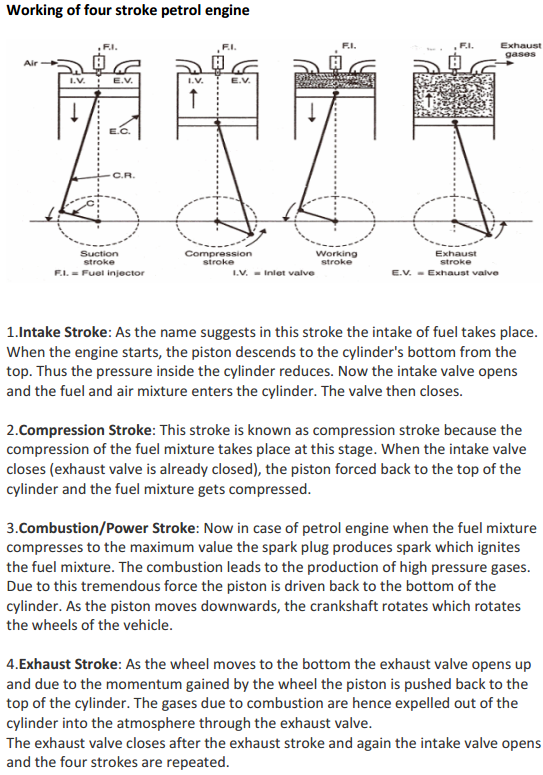

Question:

Explain the working of four stroke petrol engine with neat sketch. OR Explain with diagram how the Four stroke petrol engine works. Answer:

|

8 |

view |

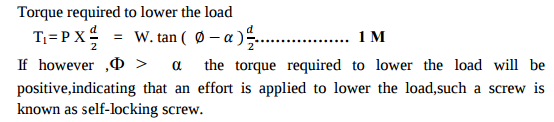

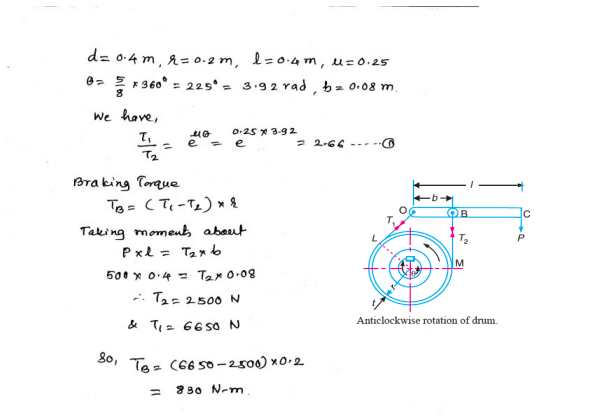

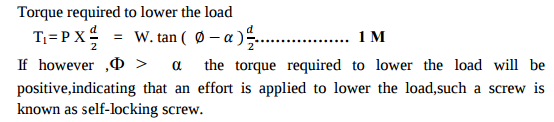

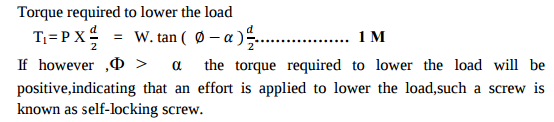

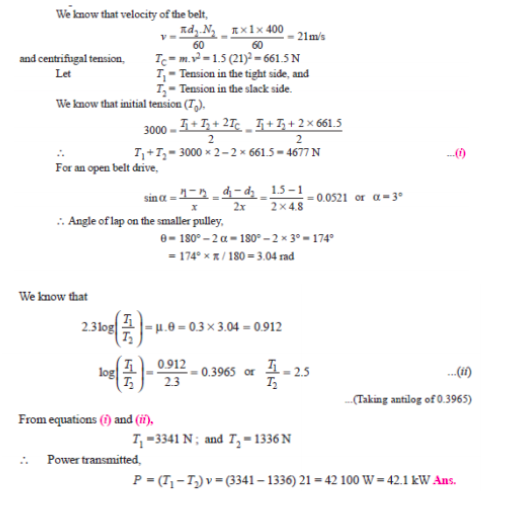

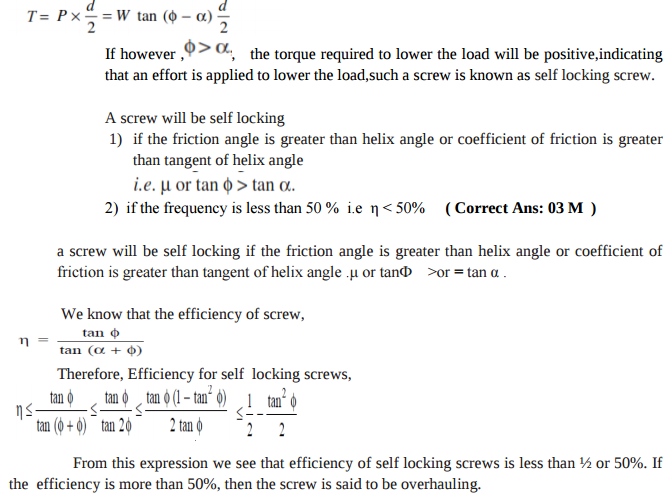

| Q 5a)(i) |

Question:

(i) Show that the efficiency of a self locking screw is less than 50% Answer:

|

8 |

view |

| Q 5a)(ii) |

Question:

What is self locking property of threads and where it is necessary? Answer:

|

8 |

view |

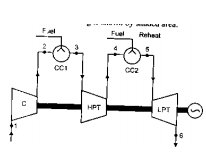

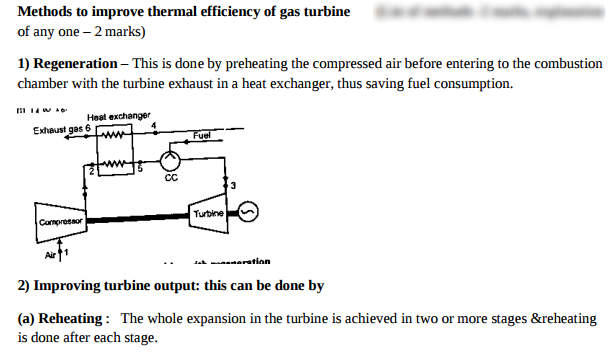

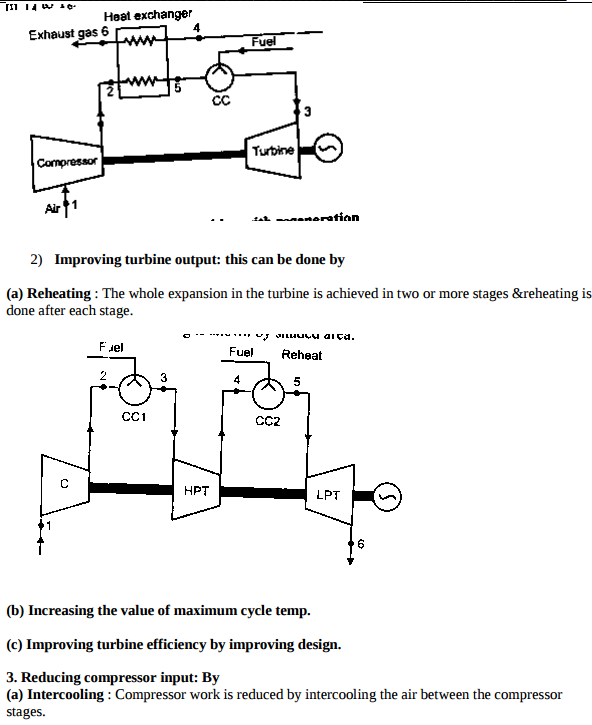

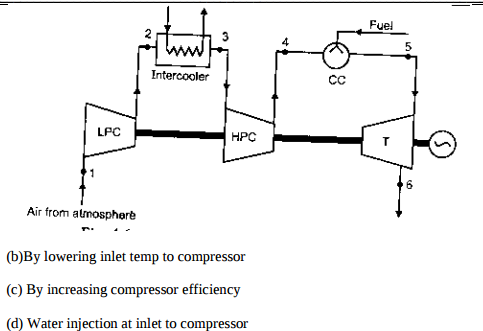

| Q 5 b ) |

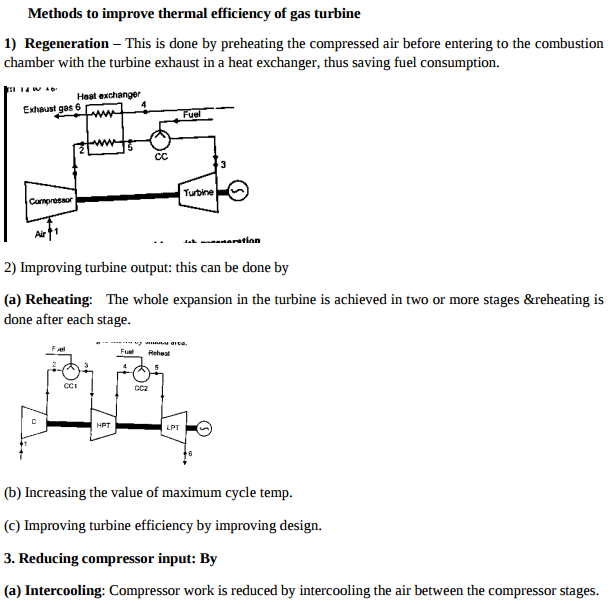

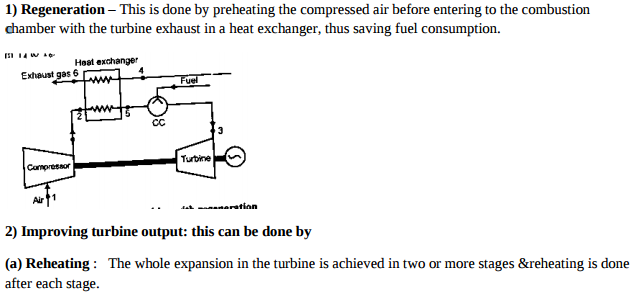

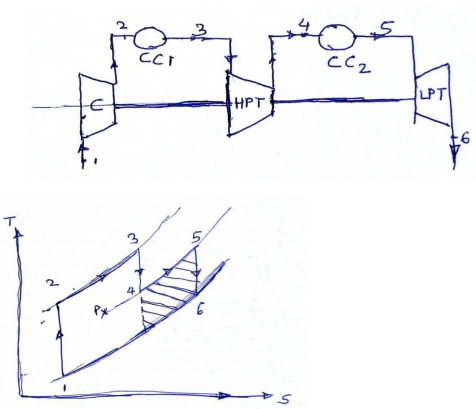

Question:

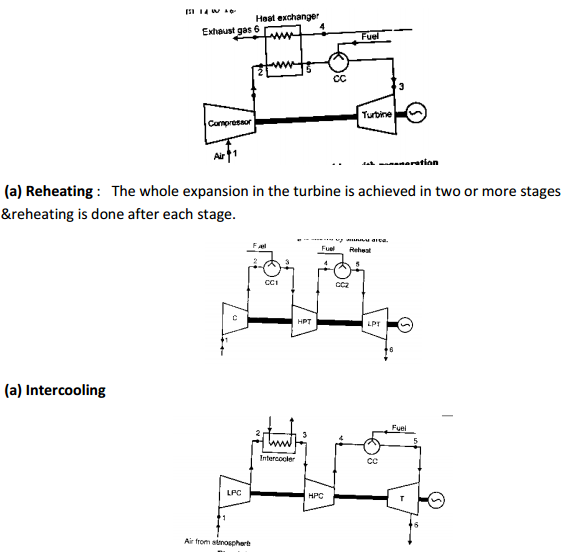

State the methods used to improve thermal efficiency of gas turbine and explain any one. Answer:

|

8 |

view |

| Q 5 b ) |

Question:

Draw and explain pneumatic meter in circuit to control of speed extension. Answer:

|

8 |

view |

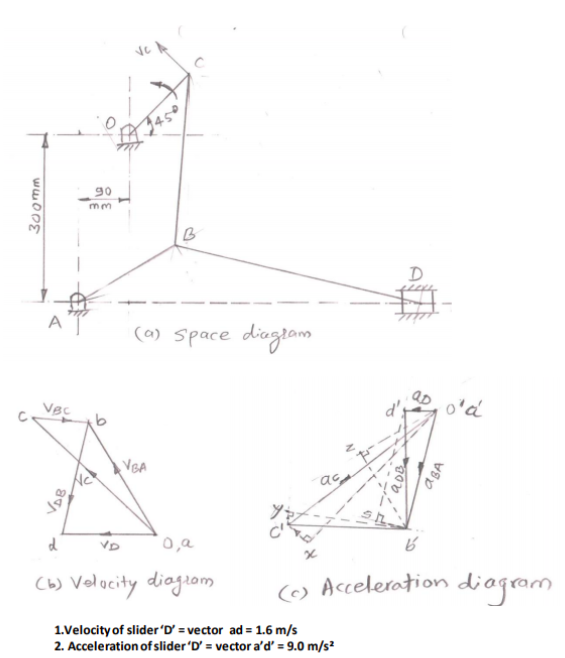

| Q 5 b ) |

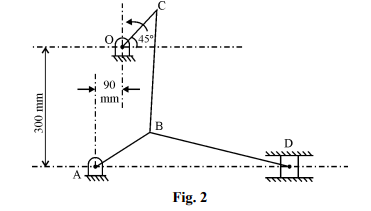

Question:

In the toggle mechanism as shown in Fig. (2), D is constrained to move on a horizontal path. The dimensions of various links are AB = 200 mm, BC = 300 mm, OC = 150 mm and BD = 450 mm. The crank OC is rotating in a counter clockwise direction at a speed of 180 rpm. Find, for given configuration (1) velocity and (2) acceleration of ‘D’.

Answer:

|

8 |

view |

| Q 5b)(i) |

Question:

(i) The extension springs are in considerably less use than compression springs. Why? Answer:

|

8 |

view |

| Q 5b)(ii) |

Question:

Explain the terms self locking and overhauling of screw. Answer:

|

8 |

view |

| Q 5 c ) |

Question:

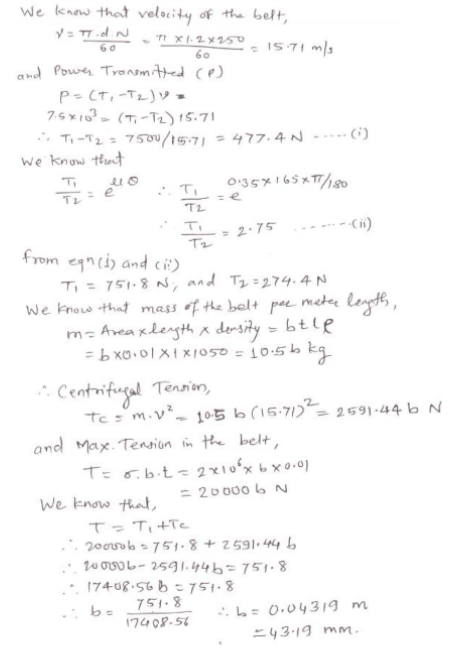

A leather belt is required to transmit 7.5 kW from a pulley 1.2 m in diameter running at 250 rpm. The angle of contact is 165o and the co-efficient of friction between the belt and the pulley is 0.35. If the safe working stress for the leather belt is 2 MPa, density of leather is 1050 kg/m3 and the thickness of belt is 10 mm, determine the width of belt, taking centrifugal tension into account. Answer:

|

8 |

view |

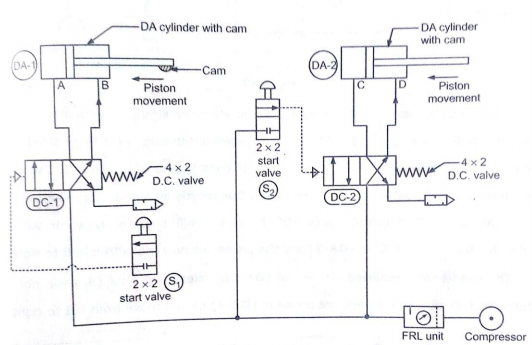

| Q 5 c ) |

Question:

Explain with neat sketch (position based) working of sequencing circuit for two double acting Air cylinders. Answer:

|

8 |

view |

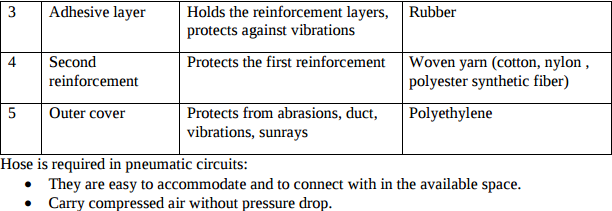

| Q 5c)(i) |

Question:

Define following terms as applied to rolling contact bearings: 1) Basic static load rating 2) Basic dynamic load rating 3) Limiting speed Answer:

|

8 |

view |

| Q 5c)(ii) |

Question:

List important physical characteristics of good bearing material. Answer:

|

8 |

view |

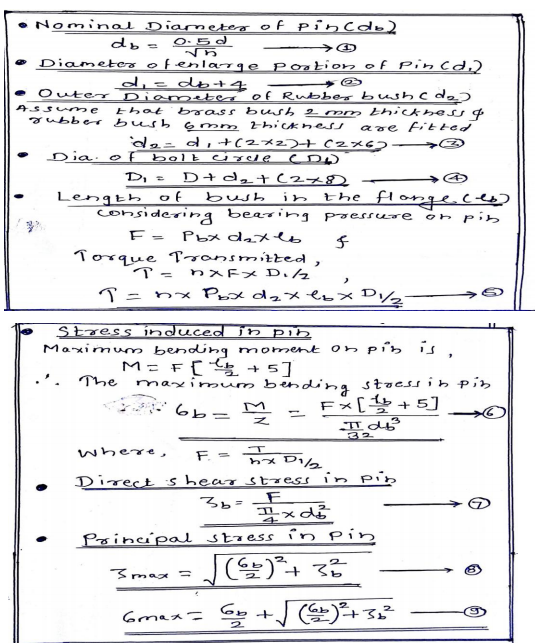

| Q 6 a ) |

Question:

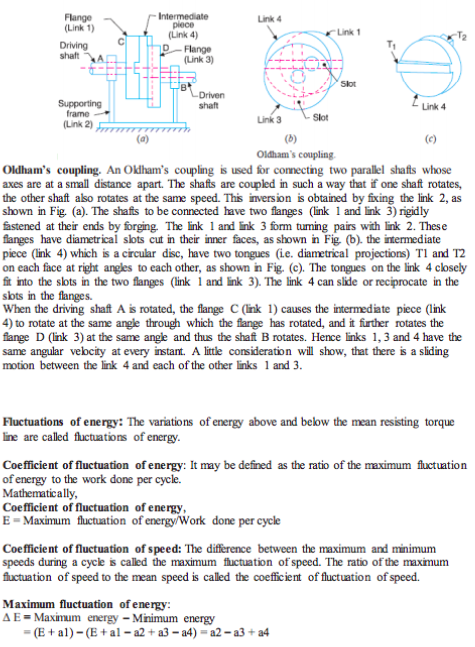

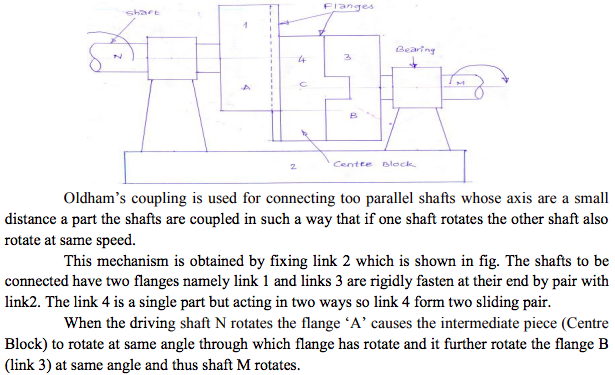

Draw a neat sketch of Oldham’s coupling and explain the working of it. Answer:

|

4 |

view |

| Q 6 a ) |

Question:

The following results were obtained during Morse test on 4 stroke petrol engine Answer:

|

4 |

view |

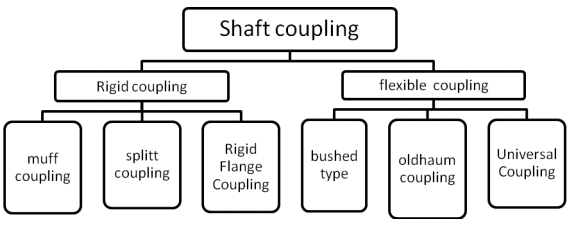

| Q 6 a ) |

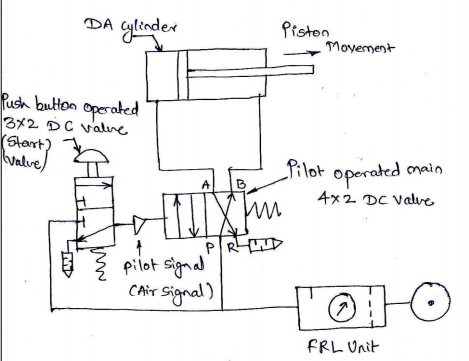

Question:

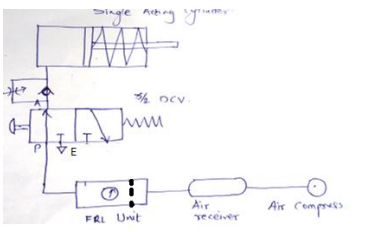

Draw speed control of single acting cylinder pneumatic circuit using 3 × 2 DC valve Answer:

|

4 |

view |

| Q 6 a ) |

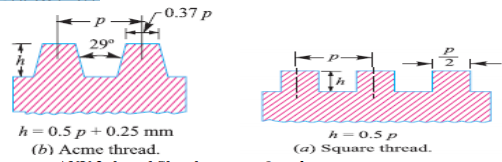

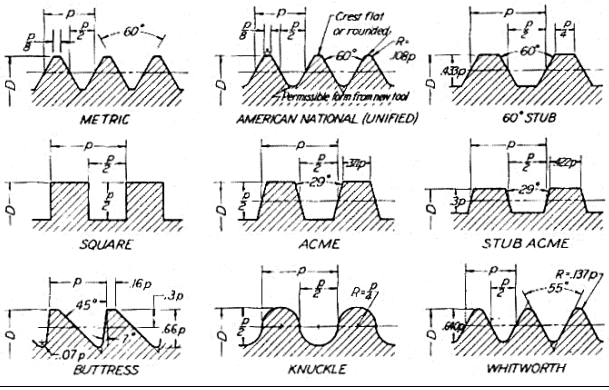

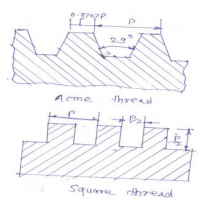

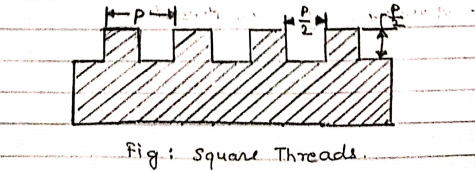

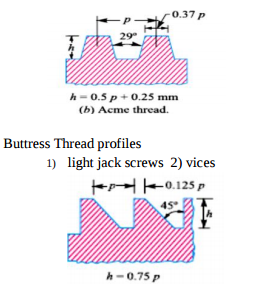

Question:

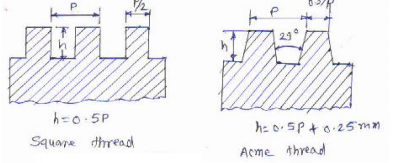

Draw profiles to square and Acme threads with full details. Which one is stronger? Answer:

|

4 |

view |

| Q 6 b ) |

Question:

Define following terms : Fluctuation of energy, co-efficient of fluctuation of energy, co-efficient of fluctuation speed, maximum fluctuation of energy. Answer:

|

4 |

view |

| Q 6 b ) |

Question:

What is the necessity of purification of air ? How to remove oil, moisture and dust from air? Answer:

|

4 |

view |

| Q 6 b ) |

Question:

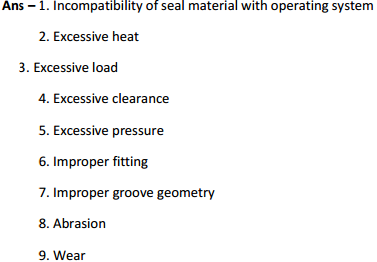

State any four reasons of failure of pneumatic seals. Answer:

|

4 |

view |

| Q 6 b ) |

Question:

State any four reasons of failure of pneumatic seals. Answer:

|

4 |

view |

| Q 6 b ) |

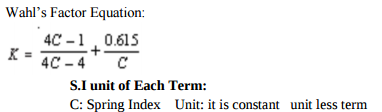

Question:

A helical valve spring is to be designed for an operating load range of approximately 135 N. The deflection of the spring for the load range is 7.5 mm. Assume spring index of 10. Permissible shear stress for the material of the spring = 480 MPa and its modulus of rigidity = 80 KN/mm2. Design the spring. Take Wahle’s factor 4 4 4 1 . , C C C 0 615 = - - + ‘C’ being the spring index Answer:

|

4 |

view |

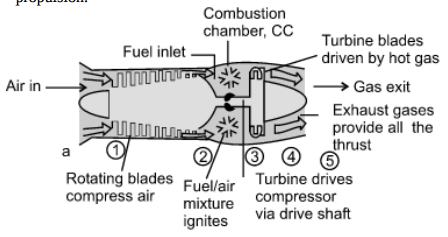

| Q 6 c ) |

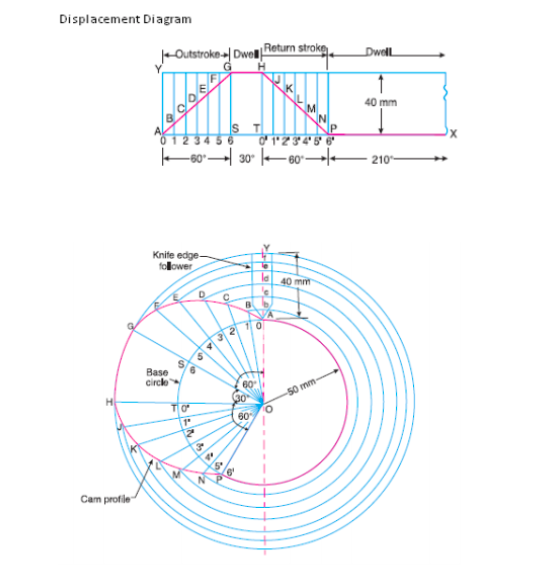

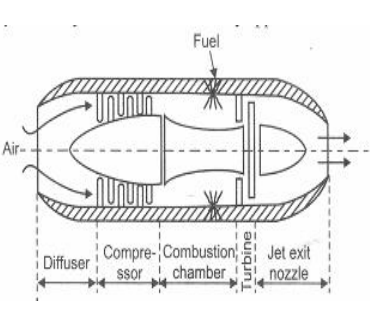

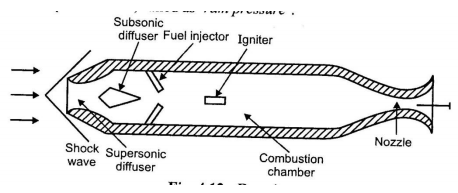

Question:

Draw the schematic diagram of turbojet engine. Answer:

|

4 |

view |

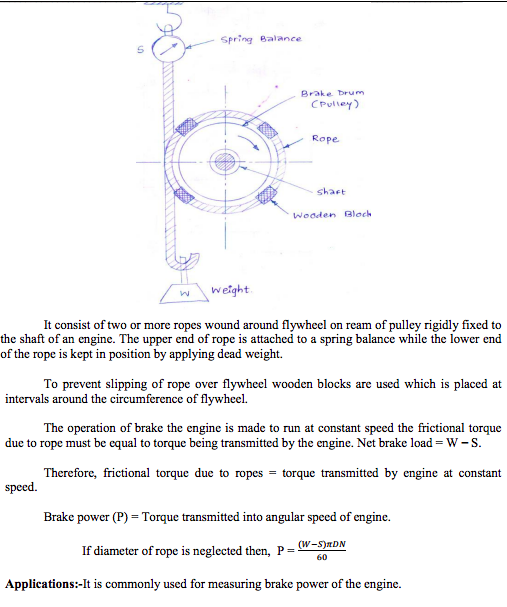

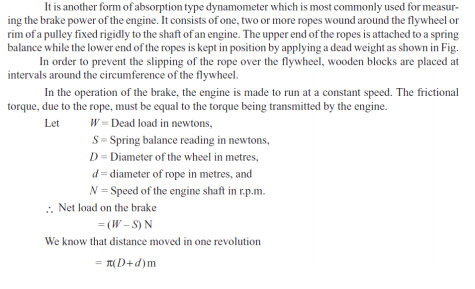

| Q 6 c ) |

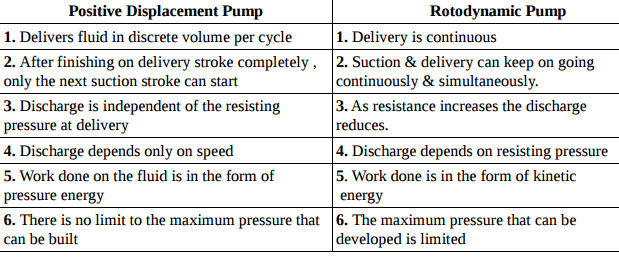

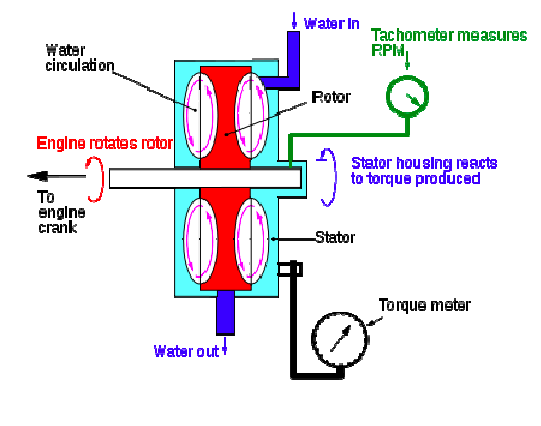

Question:

Explain the working of rope brake dynamometer with neat sketch Answer:

|

4 |

view |

| Q 6 c ) |

Question:

(c) What are the advantages of pneumatic system over hydraulic systems ? Answer:

|

4 |

view |

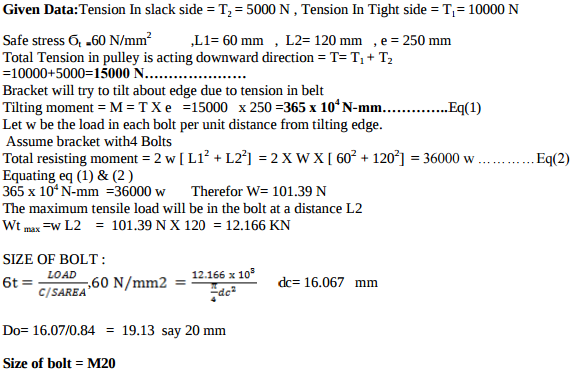

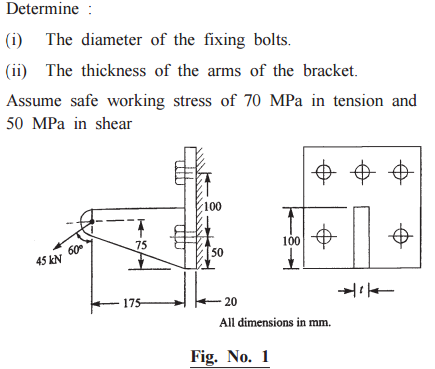

| Q 6 c ) |

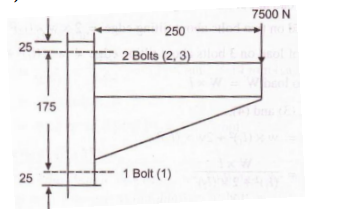

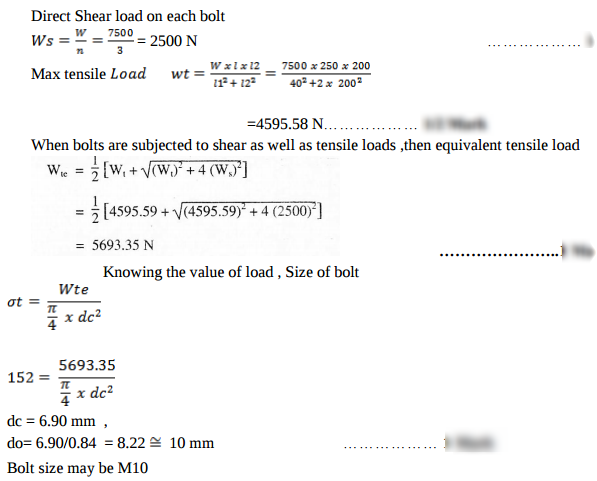

Question:

A bracket as shown in Figure No. 1 is fixed to a vertical steel column by means of five standard bolts.

Answer:

|

4 |

view |

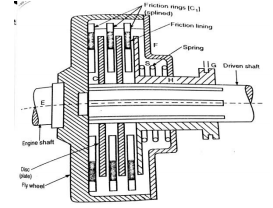

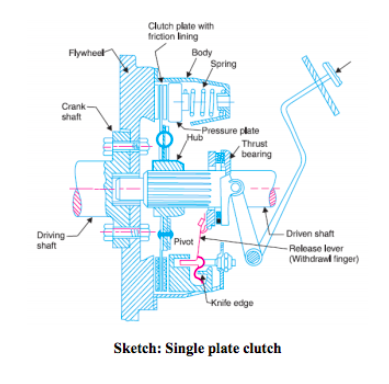

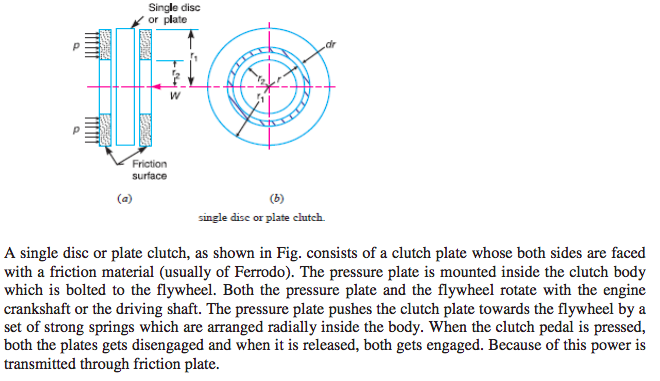

| Q 6 d ) |

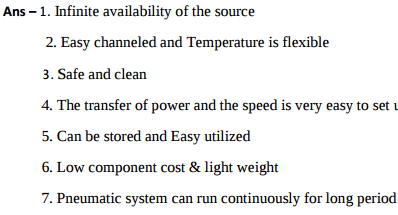

Question:

Explain the working of single plate clutch with neat diagram. Answer:

|

4 |

view |

| Q 6 d ) |

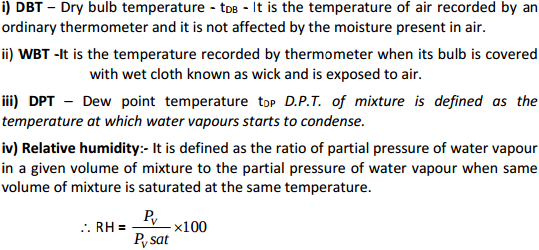

Question:

Define : i) WBT ii) DPT iii) DBT iv) Degree of saturation. Answer:

|

4 |

view |

| Q 6 d ) |

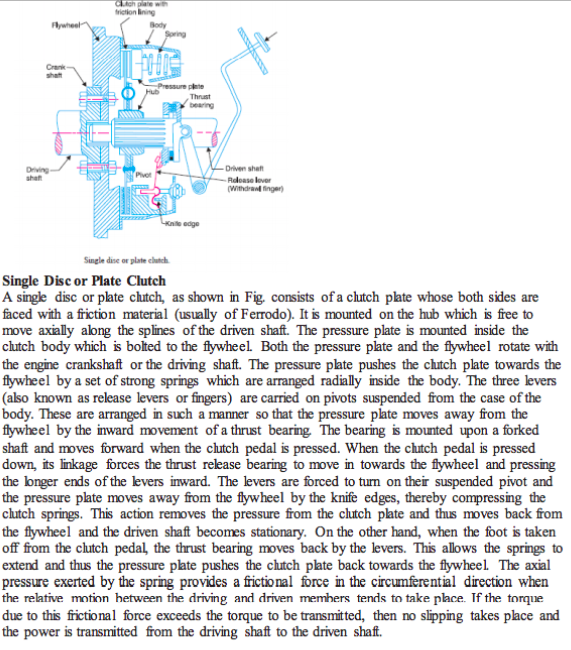

Question:

Compare positive displacement pump with Rotodynamic pump. Answer:

|

4 |

view |

| Q 6 d ) |

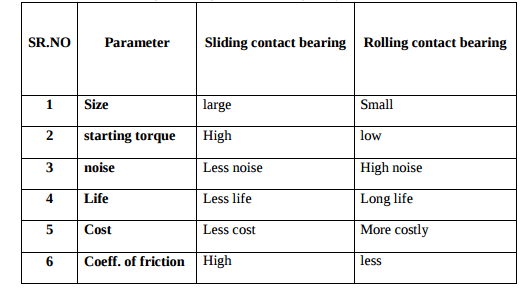

Question:

What are rolling contact bearings? State their advantages over sliding contact bearings. Answer:

|

4 |

view |

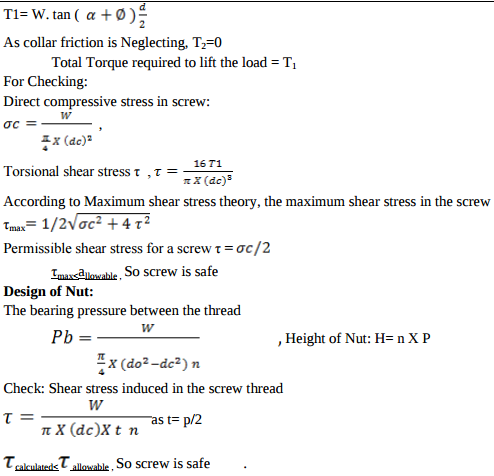

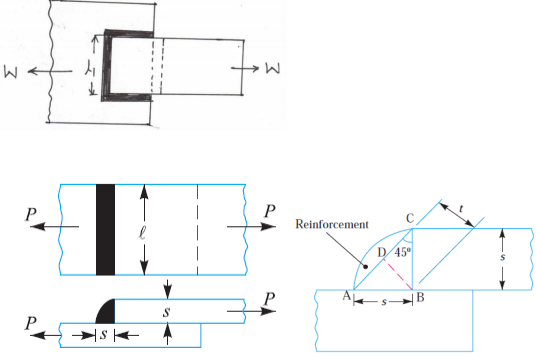

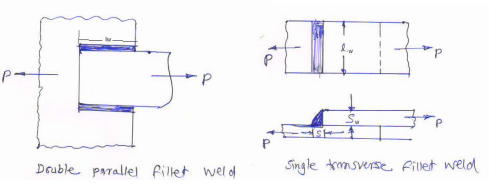

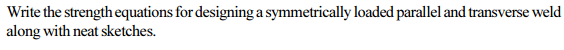

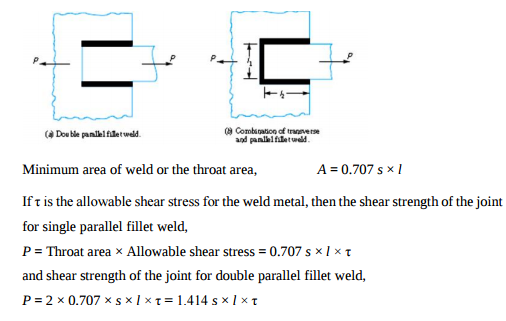

| Q 6 e ) |

Question:

State the strength equation of double parallel fillet weld and single transverse fillet weld with neat sketches Answer:

|

4 |

view |

| Q 6 e ) |

Question:

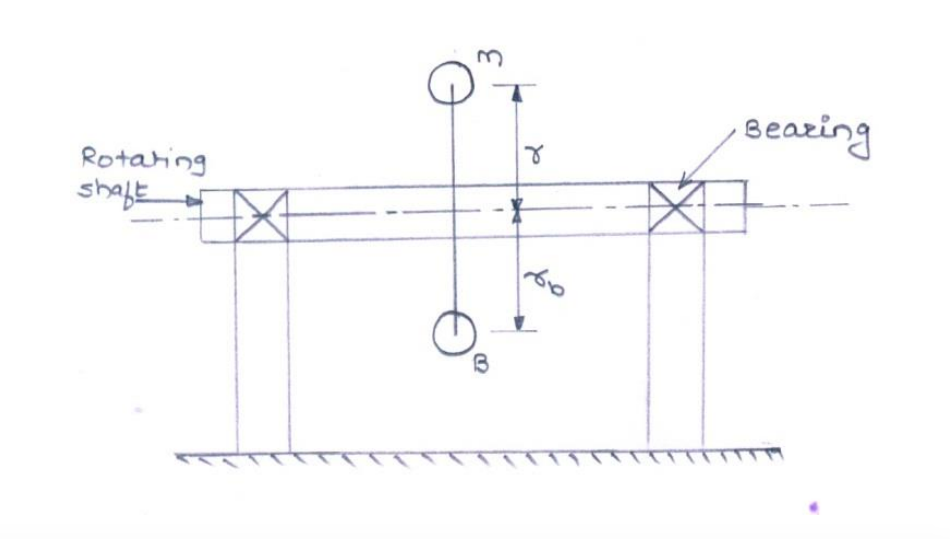

State reasons for balancing of rotating elements of machine. Explain balancing concept. Answer:

|

4 |

view |

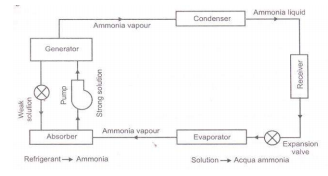

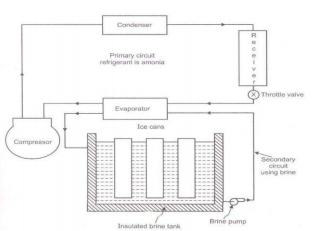

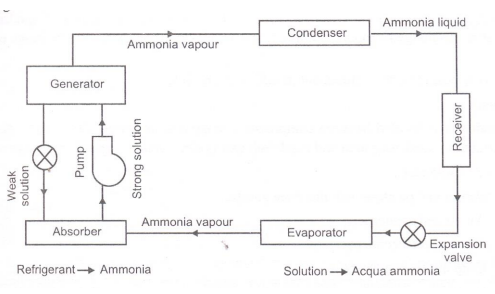

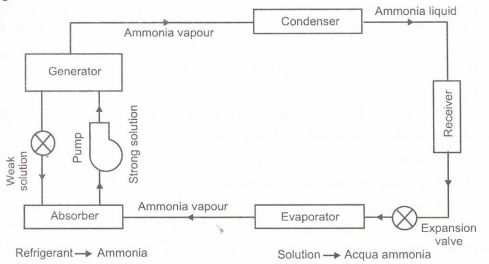

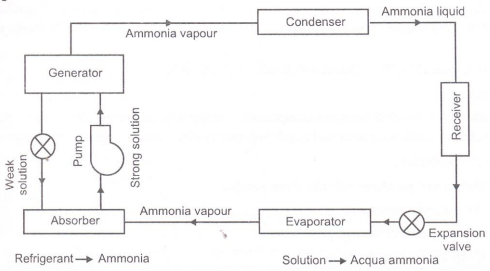

| Q 6 e ) |

Question:

Explain the working of simple vapour absorption refrigeration system. Or Explain with neat sketch vapour absorption refrigeration system. Answer:

|

4 |

view |

| Q 6 e ) |

Question:

What are the various types of Hoses used in pneumatic system Answer:

|

4 |

view |

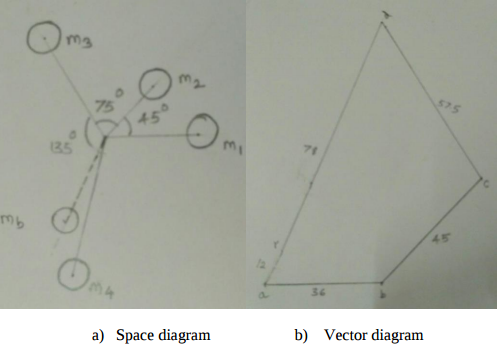

| Q 6 f ) |

Question:

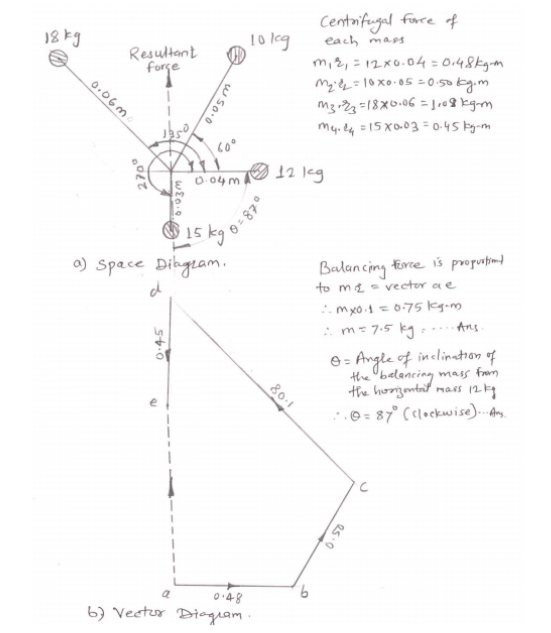

Four masses A, B, C and D are attached to a shaft and revolve in the same plane. The masses are 12 kg, 10 kg, 18 kg and 15 kg respectively and their radii of rotations are 40 mm, 50 mm, 60 mm and 30 mm. The angular position of the masses B, C and D are 60O, 135O ,and 270O from the mass ‘A’. Find the magnitude and position of the balancing mass at a radius of 100 mm. Use graphical method only. Answer:

|

4 |

view |

| Que.No | Question/Problem | marks | Link |

|---|---|---|---|

| Q 1 a ) |

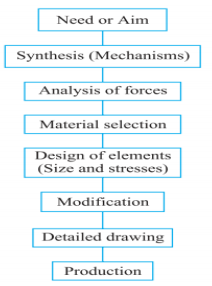

Question:

Define machine design. Answer:

mechanical elements so that the resultant machine will perform the prescribed task. OR Machine Design is the creation of new and better machines and improving the existing ones |

2 |

view |

| Q 1a)(a) |

Question:

State the four advantages and disadvantages of screw pump. Answer:

|

4 |

view |

| Q 1a)(a) |

Question:

Pappu Define kinematic link and kinematic chain. Answer:

|

2 |

view |

| Q 1a)(a) |

Question:

Define kinematic link and kinematic chain. Answer:

|

2 |

view |

| Q 1a)(a) |

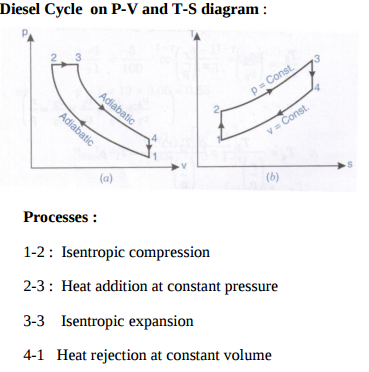

Question:

Draw p-v and T-S diagram for Diesel cycle. Name the processes involved in it. Answer:

|

4 |

view |

| Q 1a)(b) |

Question:

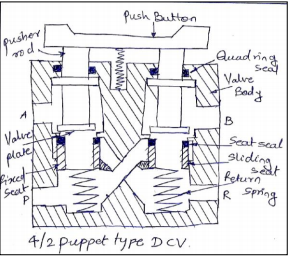

Explain the construction of 4/2 poppet valve with neat sketch & symbol. Answer:

|

4 |

view |

| Q 1a)(b) |

Question:

State types of cams. Answer:

|

2 |

view |

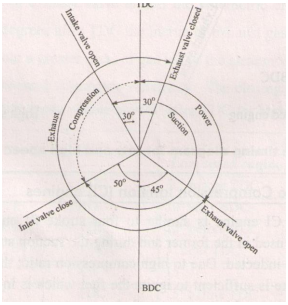

| Q 1a)(b) |

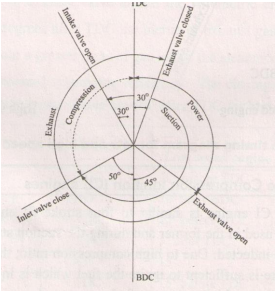

Question:

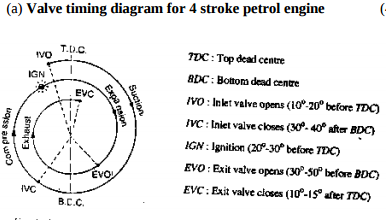

Draw actual valve timing diagram for 4-stroke petrol engine. Answer:

|

4 |

view |

| Q 1a)(c) |

Question:

State the essential properties of hydraulic fluids. Answer:

|

4 |

view |

| Q 1a)(c) |

Question:

State law of gearing. Answer:

|

2 |

view |

| Q 1a)(c) |

Question:

Classify air compressors Answer:

|

4 |

view |

| Q 1a)(d) |

Question:

Explain any two mounting methods of cylinder. Answer:

|

4 |

view |

| Q 1a)(d) |

Question:

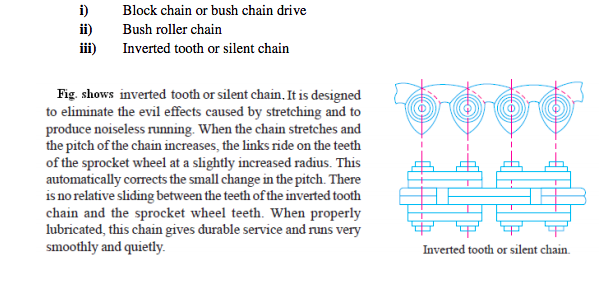

State the types of chains & sprockets. Answer:

|

2 |

view |

| Q 1a)(d) |

Question:

Classify gas turbine on the basis of Answer:

|

4 |

view |

| Q 1a)(e) |

Question:

State the function of flywheel in I.C. Engine. Answer:

|

2 |

view |

| Q 1a)(f) |

Question:

State the function of governor. Answer:

|

2 |

view |

| Q 1a)(g) |

Question:

Compare brakes and dynamometers. (any two points) Answer:

|

2 |

view |

| Q 1a)(h) |

Question:

Why is balancing of rotating parts necessary for high speed engines ? Answer:

|

2 |

view |

| Q 1a)(i) |

Question:

(a) Define : (i) Spherical pair (ii) Higher pair Answer:

|

2 |

view |

| Q 1 b ) |

Question:

State any four types of friction clutch, along with its application each. Answer:

|

4 |

view |

| Q 1 b ) |

Question:

Define slip and creep with reference to belt drive. Also state their effect on velocity ratio. Answer:

|

4 |

view |

| Q 1 b ) |

Question:

Give the composition of :- (i) FeE220: (ii) 20C8 Answer:

|

2 |

view |

| Q 1 b ) |

Question:

(b) Define : (i) Radial follower (ii) Off-set follower Answer:

|

2 |

view |

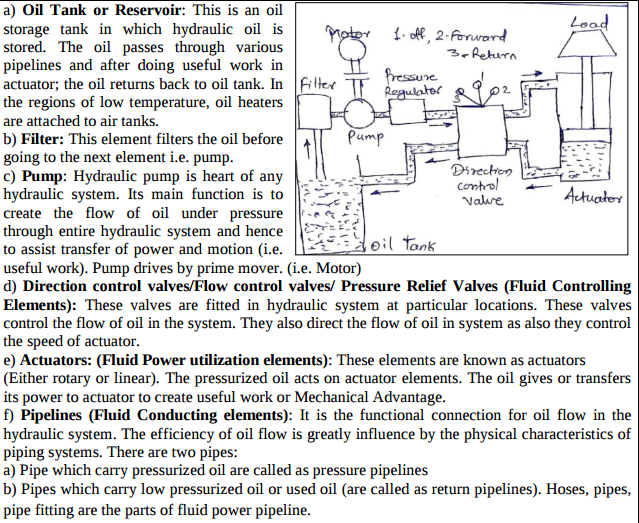

| Q 1b)(a) |

Question:

Draw general layout of hydraulic system and explain its working. Answer:

|

6 |

view |

| Q 1b)(a) |

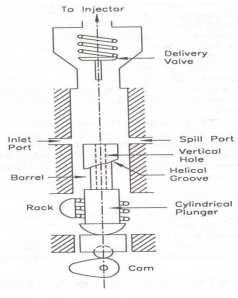

Question:

Draw a neat labelled sketch of fuel injection pump. Give its function. Answer:

|

6 |

view |

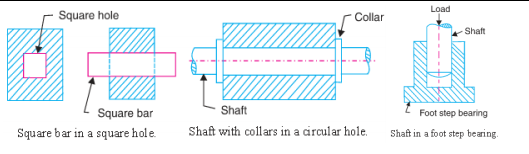

| Q 1b)(a) |

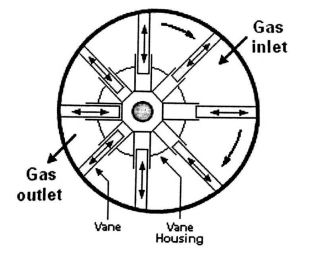

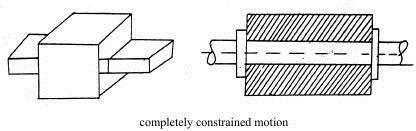

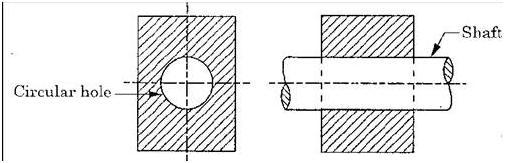

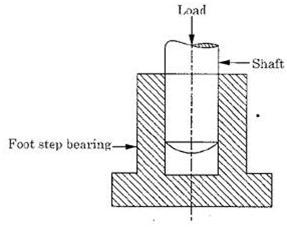

Question:

Define completely constrained motion and successfully constrained motion with neat sketch. State one example of each. Answer:

|

4 |

view |

| Q 1b)(b) |

Question:

With a neat sketch explain pressure compensated flow control valve. Draw symbol of it. Answer:

|

6 |

view |

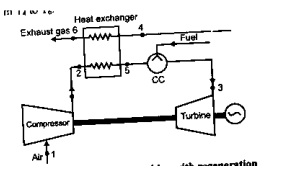

| Q 1b)(b) |

Question:

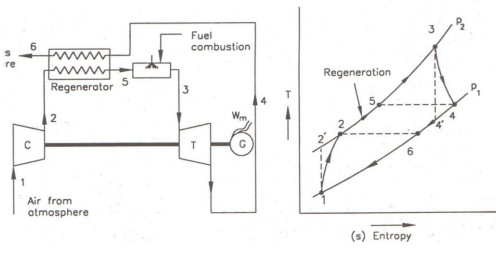

Explain regeneration method to improve thermal efficiency of gas turbine with the help of Answer:

|

6 |

view |

| Q 1b)(b) |

Question:

State function of clutch. Explain working principle of clutch. Answer:

|

4 |

view |

| Q 1b)(ii) |

Question:

2) Define : a) Ductility b) Toughness c) Creep Answer:

|

8 |

view |

| Q 1 c ) |

Question:

State four types of loads acting on machine elements Answer:

|

2 |

view |

| Q 1 c ) |

Question:

What do you mean by crowning of pulleys in flat belt drive ? State its use. Answer:

|

2 |

view |

| Q 1 d ) |

Question:

What do you mean by creep? Answer:

|

2 |

view |

| Q 1 d ) |

Question:

Define initial tension in belt drive & state its effect. Answer:

|

2 |

view |

| Q 1 e ) |

Question:

Define Ergonomics. Answer:

|

2 |

view |

| Q 1 e ) |

Question:

Define fluctuation of speed and fluctuation of energy in case of flywheel. Answer:

|

2 |

view |

| Q 1 f ) |

Question:

Give two applications of knuckle joint. Answer:

|

2 |

view |

| Q 1 f ) |

Question:

Define the sensitivity in relation to governer. State its significance. Answer:

|

2 |

view |

| Q 1 g ) |

Question:

Define following terms of spring: Answer:

known as spring stiffness or spring constant. Mathematically, Spring rate, k = W / δ Where, W = Load δ = Deflection of the spring (ii) Spring index: The spring index is defined as the ratio of the mean diameter of the coil to the diameter of the wire. Mathematically, Spring index, C = D / d Where, D = Mean diameter of the coil d = Diameter of the wire |

2 |

view |

| Q 1 h ) |

Question:

How do you express the life of bearings? Answer:

|

2 |

view |

| Q 1 h ) |

Question:

State the adverse effect of imbalance of rotating elements of machine. Answer:

|

2 |

view |

| Q 1 i ) |

Question:

Draw the different thread profiles used for power screws. Answer:

|

2 |

view |

| Q 1 j ) |

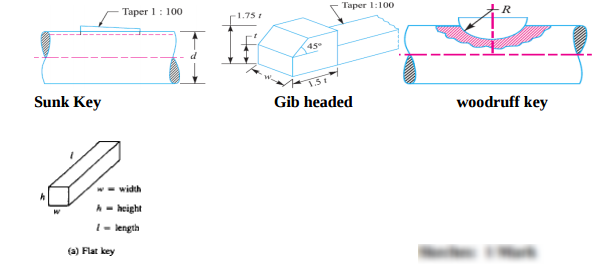

Question:

State four types of keys. Answer:

|

2 |

view |

| Q 1 k ) |

Question:

Give two examples, where screwed joints are preferred over welded joints. Answer:

|

2 |

view |

| Q 1 l ) |

Question:

State any four applications of rolling contact bearings. Answer:

|

2 |

view |

| Q 1 m ) |

Question:

What are the requirement of a good coupling? Answer:

|

2 |

view |

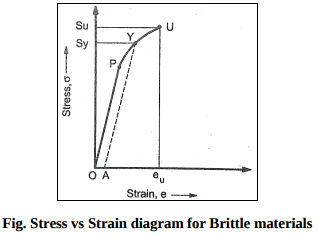

| Q 1 n ) |

Question:

Draw stress – strain diagram for brittle material. Answer:

|

2 |

view |

| Q 2 a ) |

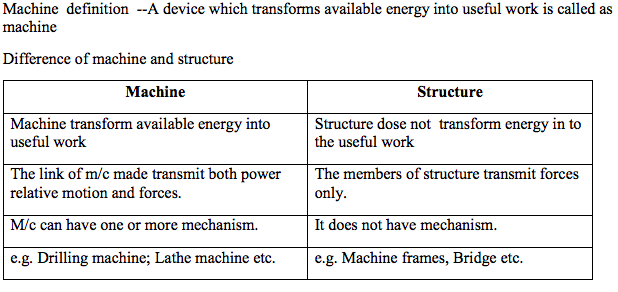

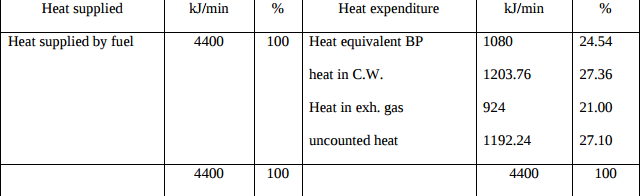

Question:

Differentiate between machine and structure. Answer:

Machine Structure All parts / links have relative motion No relative motion between the links It transforms the available energy into some useful work No energy transformations The kinematic link of a machine may transmit both power and The member of the structure transmit forces only |

4 |

view |

| Q 2 a ) |

Question:

What is a machine ? Differentiate between a machine and a structure. Answer:

Machine Structure All parts / links have relative motion No relative motion between the links It transforms the available energy into some useful work No energy transformations The kinematic link of a machine may transmit both power and motion The member of the structure transmit forces only Examples: I.C. Engine, Machine tools, steam engine, type writer, etc. Example: Truss of roof, frame of machine, truss of bridge Studied under 'Dynamics' Studied under 'Statics' |

4 |

view |

| Q 2 a ) |

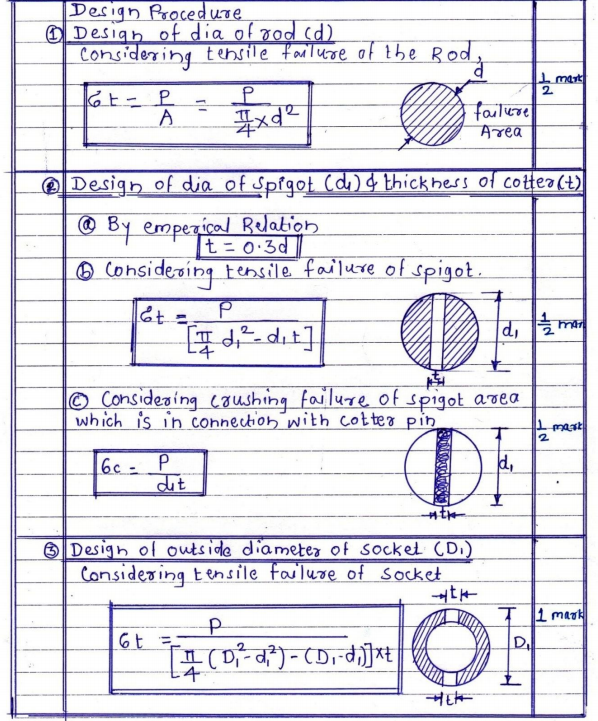

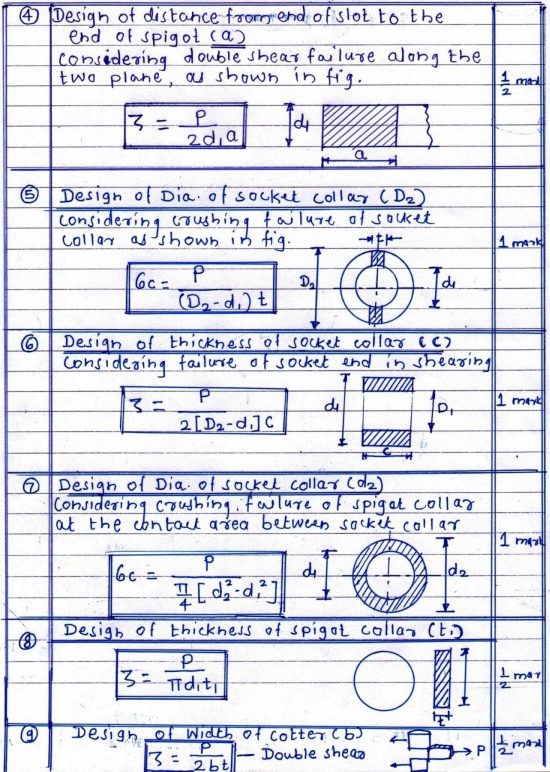

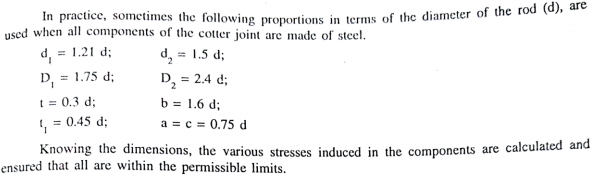

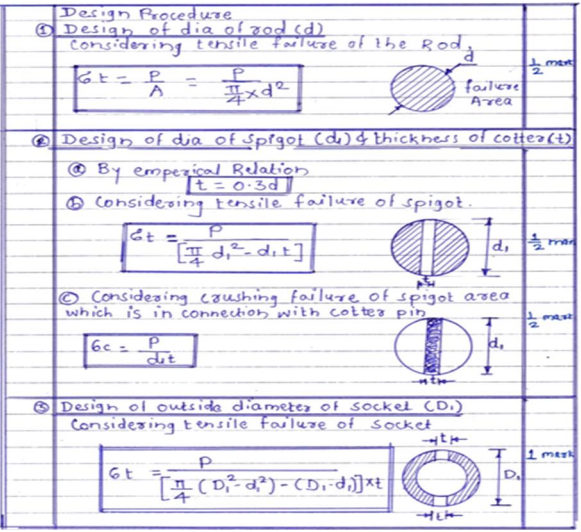

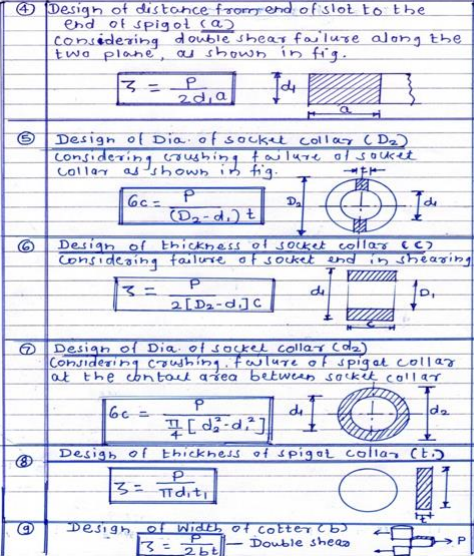

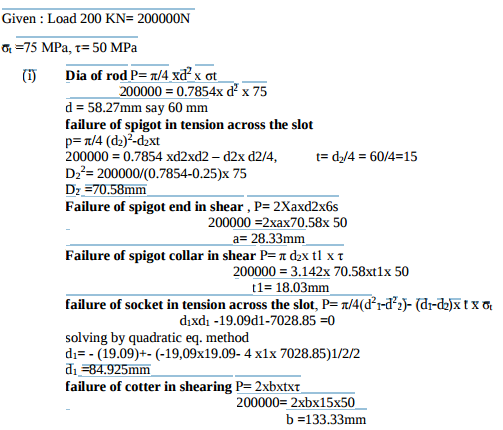

Question:

Explain various failures to be considered in designing a cotter joint along with the necessary sketches and strength equations. Answer:

|

8 |

view |

| Q 2 a ) |

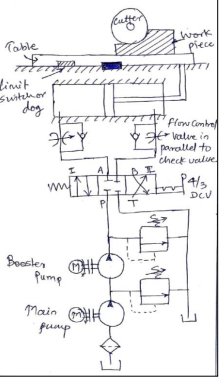

Question:

Explain with neat sketch the working of hydraulic circuit for milling machine. Answer:

|

8 |

view |

| Q 2 a ) |

Question:

Reciprocating air compressor draws 6 kg of air per minute at 25°C. It compresses the air Answer:

|

8 |

view |

| Q 2 b ) |

Question:

Explain with the neat sketch working of crank and slotted lever quick return mechanism. Answer:

|

4 |

view |

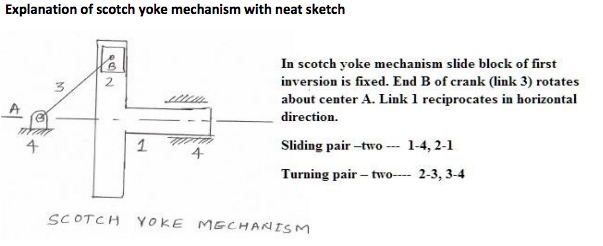

| Q 2 b ) |

Question:

Describe with neat sketch the working of scotch yoke mechanism. Answer:

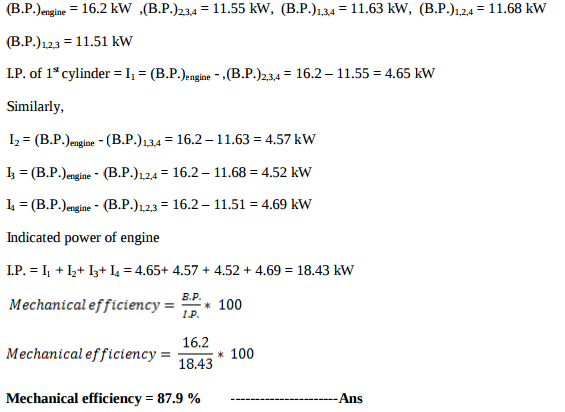

|

4 |

view |

| Q 2 b ) |

Question:

Name any eight pipe or tube fitting with their application. Answer:

|

8 |

view |

| Q 2 b ) |

Question:

State the theories of elastic failure. Explain maximum normal stress theory and maximum shear stress theory with equations. Or Explain Maximum shear stress theory. {Maximum shear stress theory is also called as?} Answer:

|

8 |

view |

| Q 2 b ) |

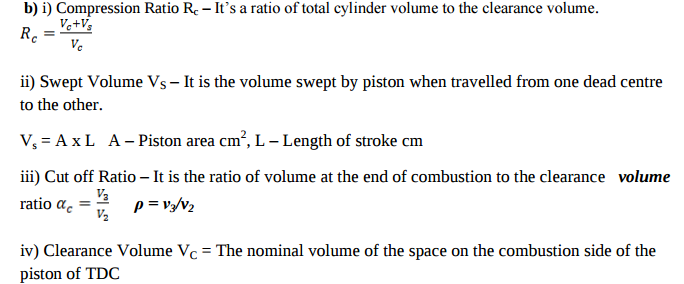

Question:

List various types of air motors. Explain vane type air motor with neat sketch. Answer:

|

8 |

view |

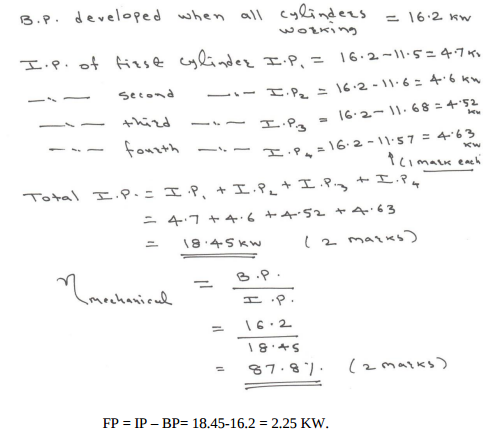

| Q 2 c ) |

Question:

The following results were obtained during Morse test on 4-stroke petrol engine. Brake power developed when all cylinders working = 16.2 kW Answer:

|

8 |

view |

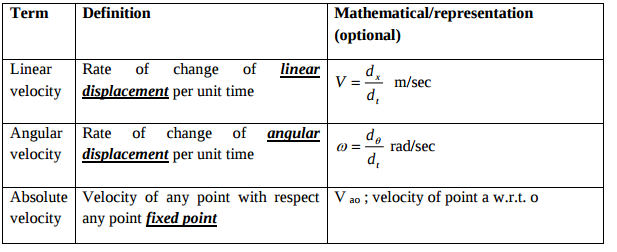

| Q 2 c ) |

Question:

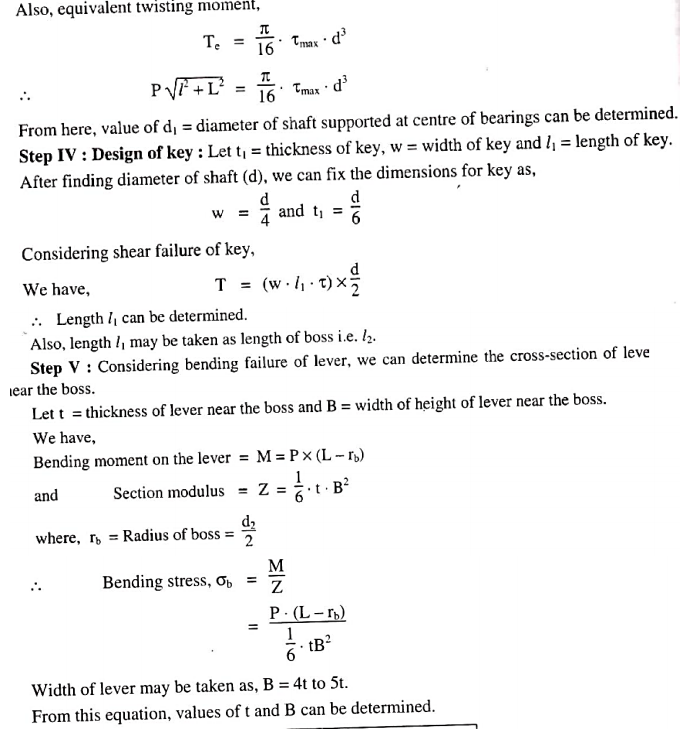

Define linear velocity, angular velocity, absolute velocity and state the relation between linear velocity and angular velocity Answer:

|

4 |

view |

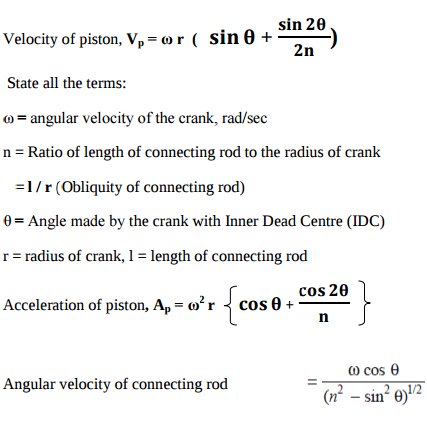

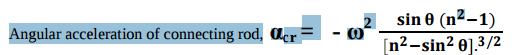

| Q 2 c ) |

Question:

Explain the inter-relation between linear and angular velocity, linear and angular acceleration with suitable example. Answer:

|

4 |

view |

| Q 2 c ) |

Question:

What is seal ? Classify seals according to shape. State the factors for seal selection. Answer:

|

8 |

view |

| Q 2c)(i) |

Question:

(i) State and describe in brief about four ergonomic considerations in the designing of machine elements. Answer:

|

8 |

view |

| Q 2c)(ii) |

Question:

(ii) How will select bearing from manufacturer catalogue? Answer:

|

8 |

view |

| Q 2 d ) |

Question:

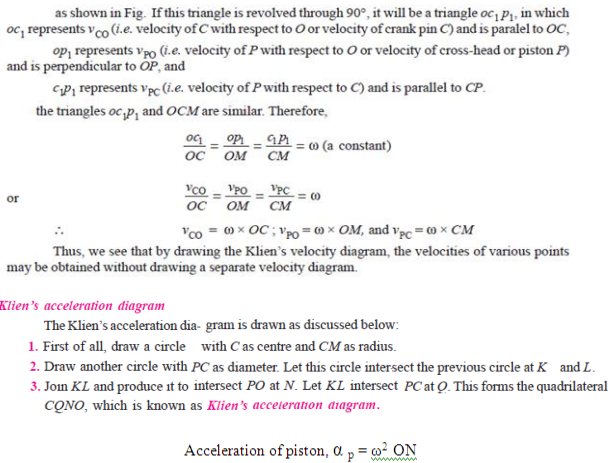

Explain the Klein’s construction to determine velocity and acceleration of single slider crank mechanism Answer:

|

4 |

view |

| Q 2 d ) |

Question:

Explain the Klein’s construction to determine velocity and acceleration of a link in an I.C. engine mechanism. Answer:

|

4 |

view |

| Q 2 e ) |

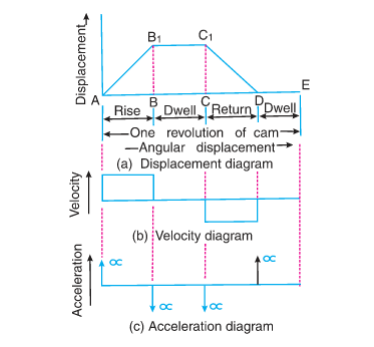

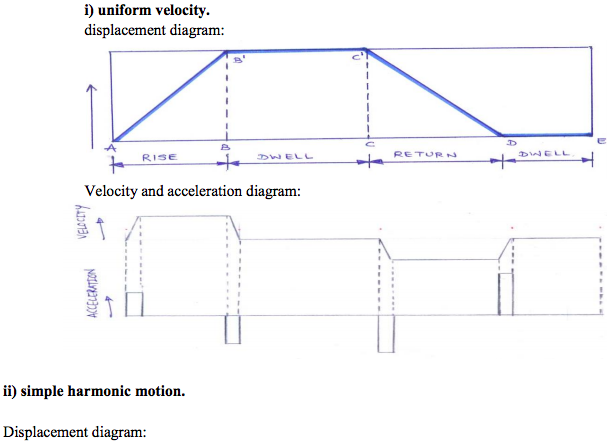

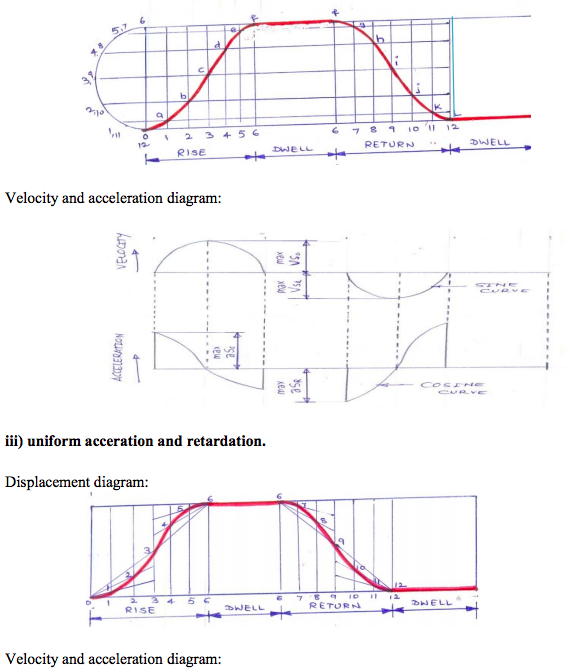

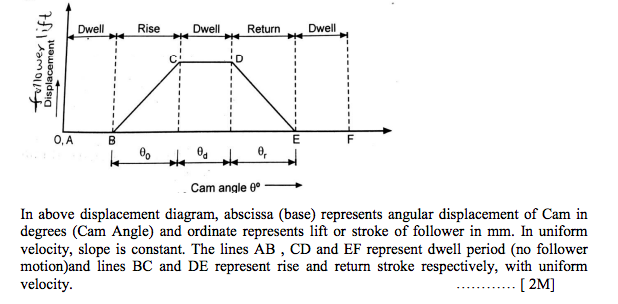

Question:

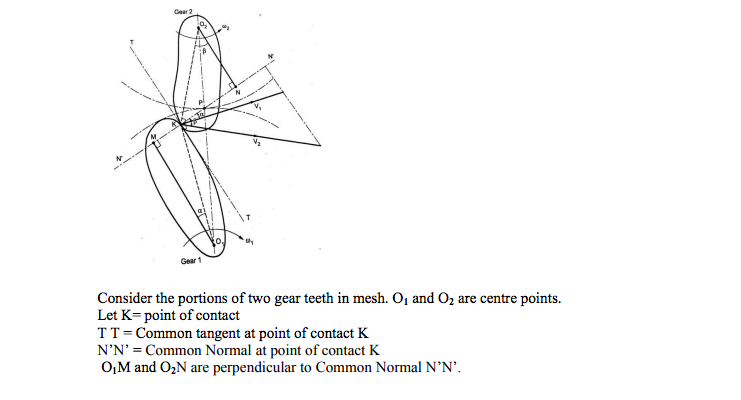

Draw the labelled displacement, velocity and acceleration diagrams for a follower when it moves with uniform velocity. Answer:

|

4 |

view |

| Q 2 e ) |

Question:

Draw the labelled displacement, velocity and acceleration diagrams for a follower when it moves with simple harmonic motion. Answer:

|

4 |

view |

| Q 2 f ) |

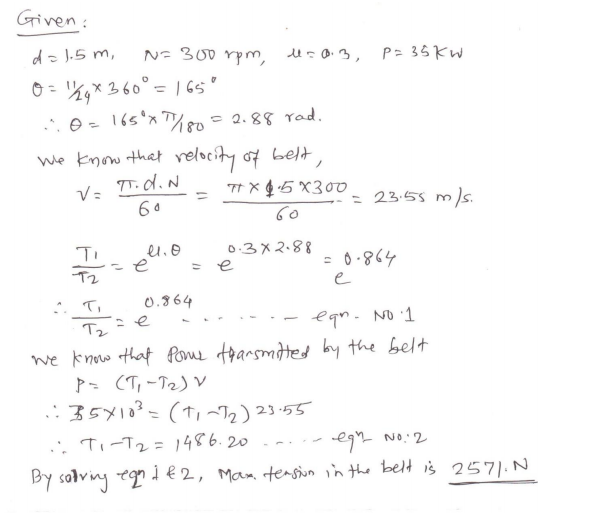

Question:

A flat belt drive is required to transmit 35 kW from a pulley of 1.5 m effective diameter running at speed of 300 rpm. The angle of contact is spread over 11/24 of the circumference co-efficient of friction for the surface is 0.3. Determine the maximum tension in the belt. Answer:

|

4 |

view |

| Q 2 f ) |

Question:

A pulley rotating at 50 m/s transmits 40 kW. The safe pull in belt is 400 N/cm width of belt. The angle of lap is 170º. If coefficient of friction is 0.24, find required width of belt. Answer:

|

4 |

view |

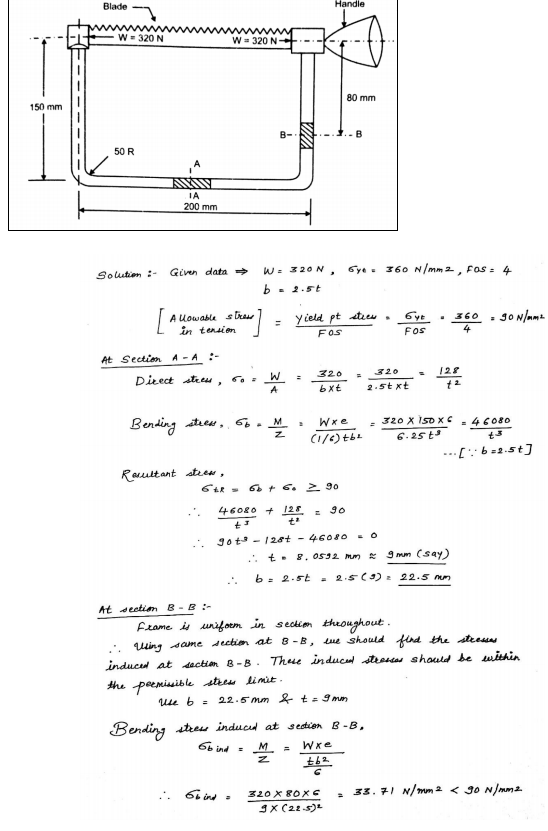

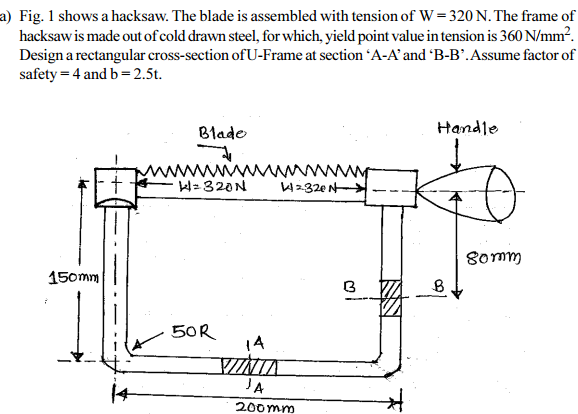

| Q 3 ) |

Question:

Fig.1Show of hacksaw The belt is assembled with tensoion

Answer:

|

8 |

view |

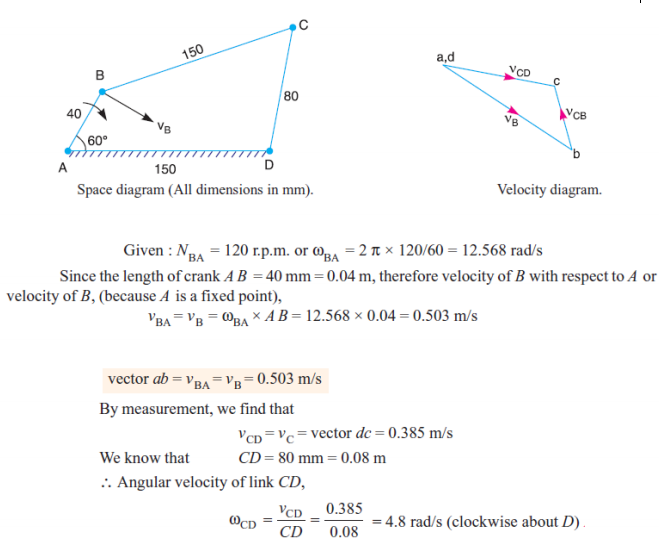

| Q 3 a ) |

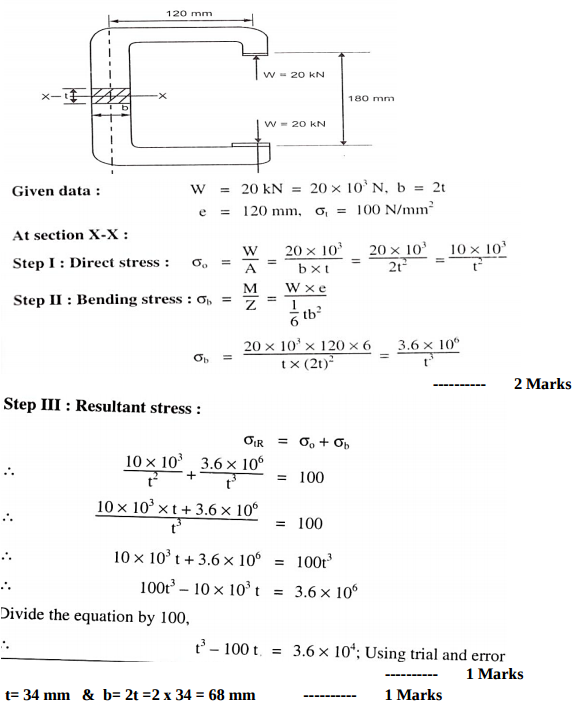

Question:

In a four bar chain ABCD, AD is fixed and is 150 mm long. The crank AB is 40 mm long and rotates at 120 r.p.m. clockwise, while the link CD = 80 mm oscillates about D. BC and AB are of equal length. Find the angular velocity of link CD when angle BAD = 60. Answer:

|

4 |

view |

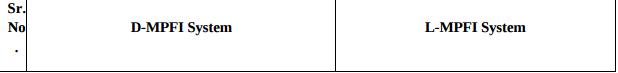

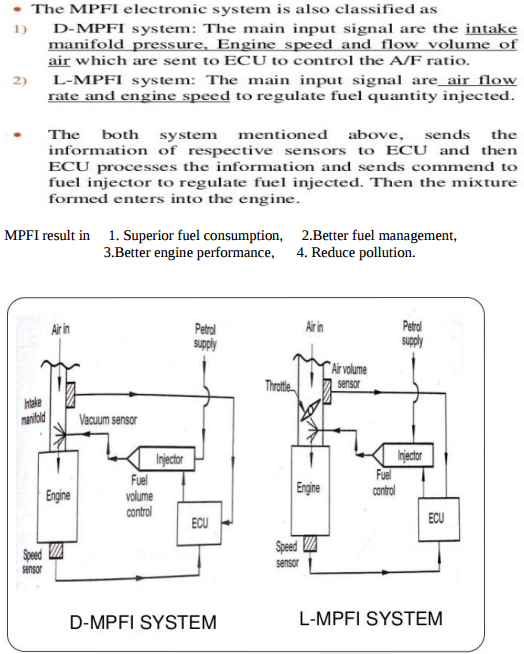

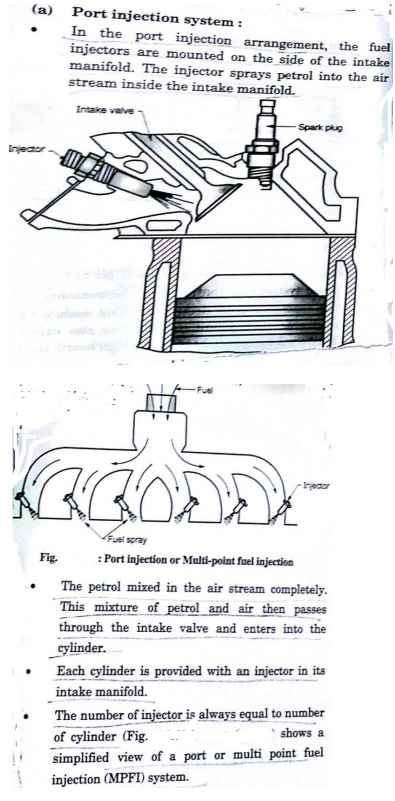

| Q 3 a ) |

Question:

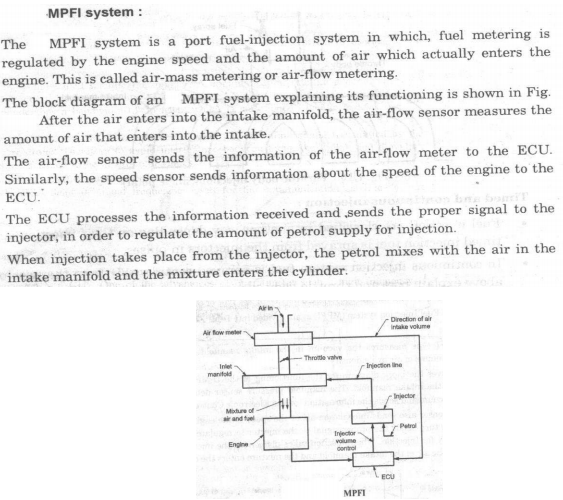

Explain MPFI with neat sketch. Answer:

|

4 |

view |

| Q 3 a ) |

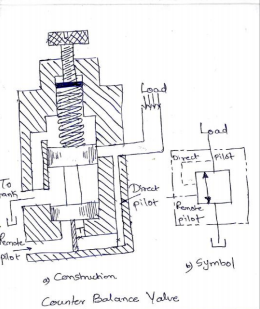

Question:

Explain the working of counter balance valve in hydraulic circuit. Answer:

|

4 |

view |

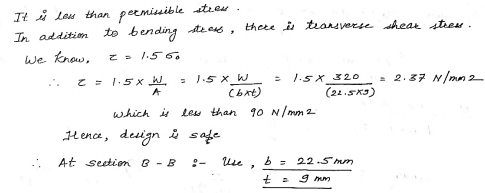

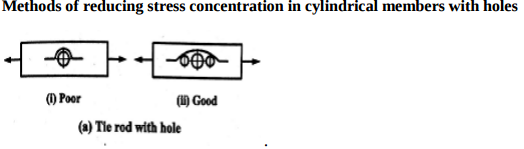

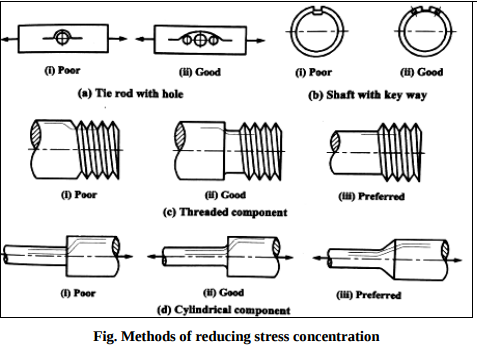

| Q 3a)(i) |

Question:

Explain with neat sketches only (i) Methods of reducing stress concentration in cylindrical members with shoulders. (ii) Methods of reducing stress concentration in cylindrical members with holes.

Answer:

|

4 |

view |

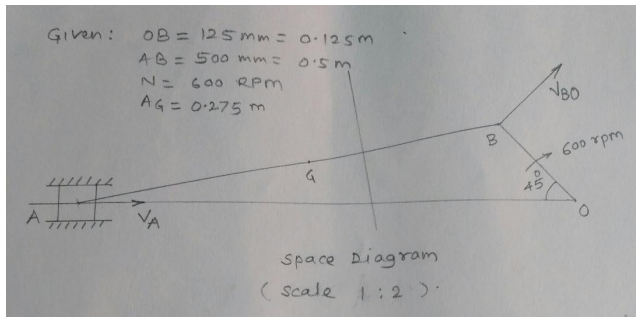

| Q 3 b ) |

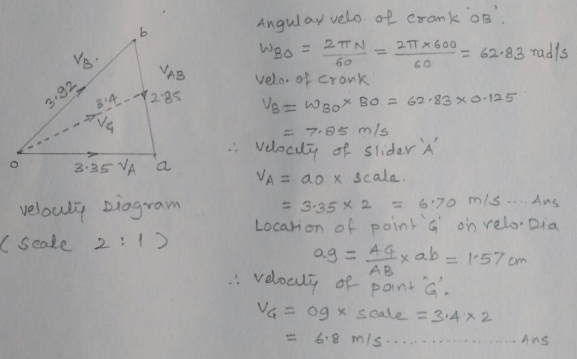

Question:

In a slider crank mechanism, the length of crank OB and connecting rod AB are 125 mm and 500 mm respectively. The centre of gravity G of the connecting rod is 275 mm from the slider. The crank speed is 600 rpm clockwise. When the crank has turned 45 from the inner dead centre position, determine : (i) Velocity of slider ‘A’, (ii) Velocity of the point ‘G’ graphically. Answer:

|

4 |

view |

| Q 3 b ) |

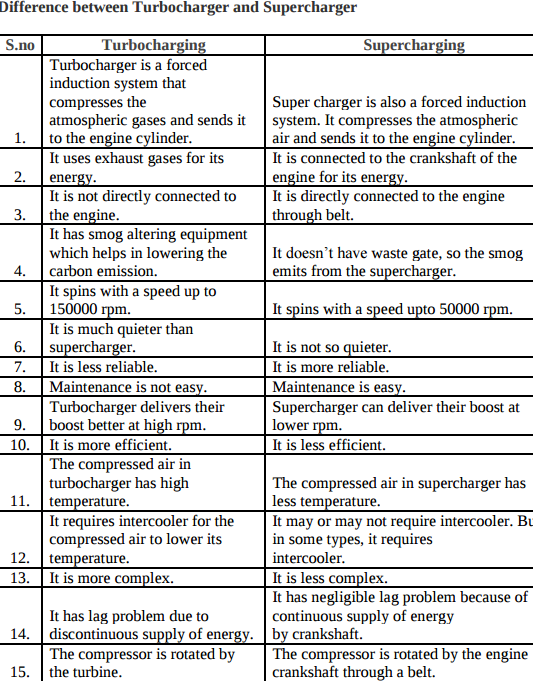

Question:

Differentiate supercharging and turbocharging in I.C. engine. Answer:

|

4 |

view |

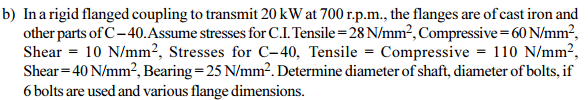

| Q 3 b ) |

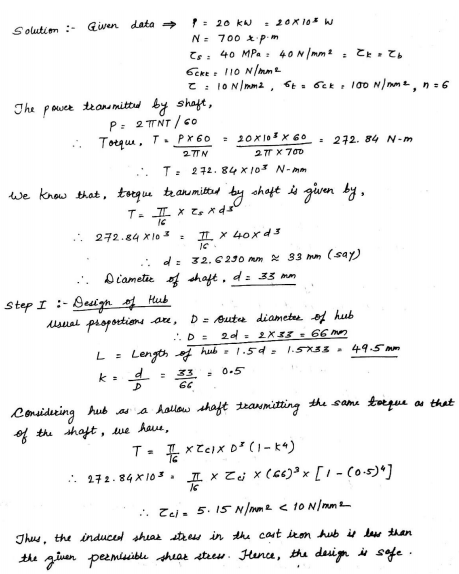

Question:

In a rigid flaninged complended to transmit 20K.W at 700.r.p.m

Answer:

|

8 |

view |

| Q 3 b ) |

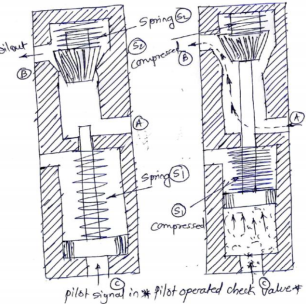

Question:

Discuss pilot operated check valve with neat sketch. Answer:

|

4 |

view |

| Q 3 c ) |

Question:

Explain slip and creep phenomenon in belts. Answer:

|

4 |

view |

| Q 3 c ) |

Question:

State the advantages of lubricant additives (any four). Answer:

|

4 |

view |

| Q 3 c ) |

Question:

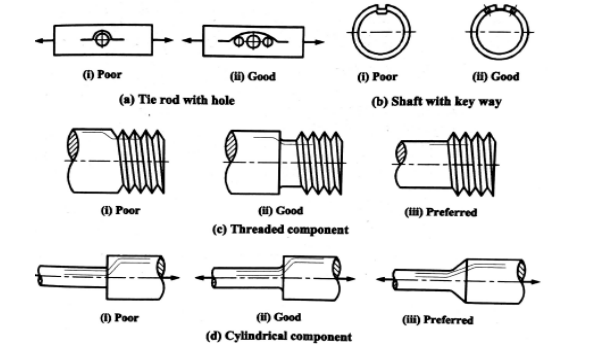

Define stress concentration. What are the causes of stress concentration? State any four methods of reducing stress concentration with neat sketches. Answer:

|

8 |

view |

| Q 3 c ) |

Question:

Explain with neat sketch the working of meter out hydraulic circuit. Answer:

|

4 |

view |

| Q 3 c ) |

Question:

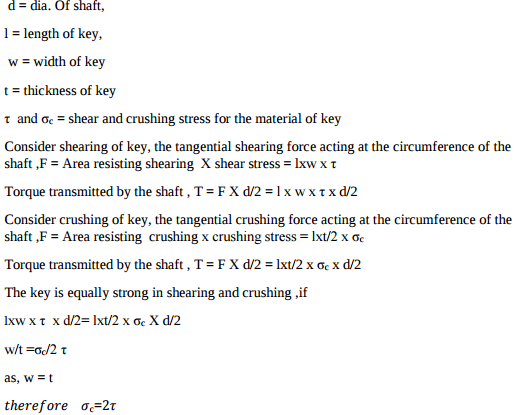

What are the considerations in design of dimensions of formed and parallel key having rectangular cross section?

Answer:

|

4 |

view |

| Q 3 d ) |

Question:

Draw the neat sketch of diaphragm clutch and explain its working. Answer:

|

4 |

view |

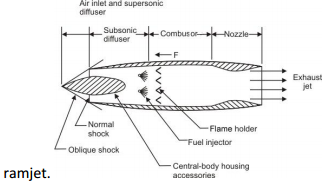

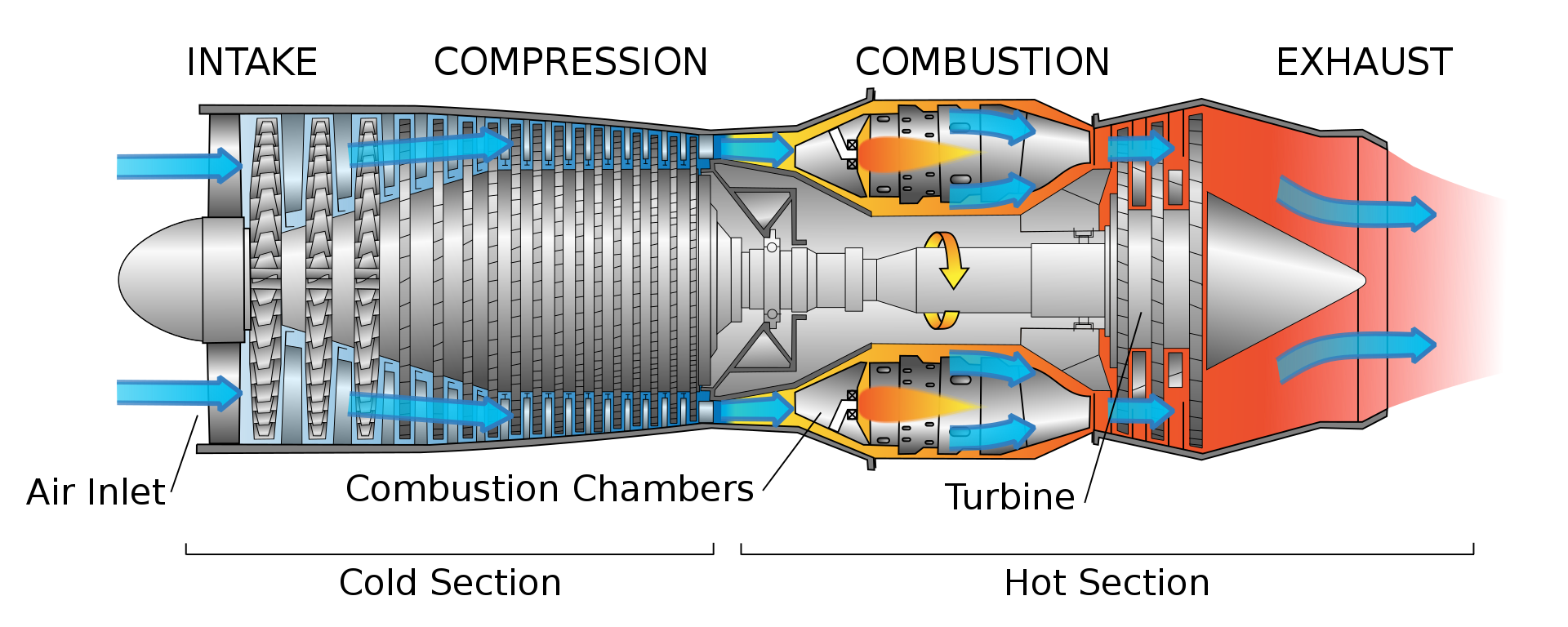

| Q 3 d ) |

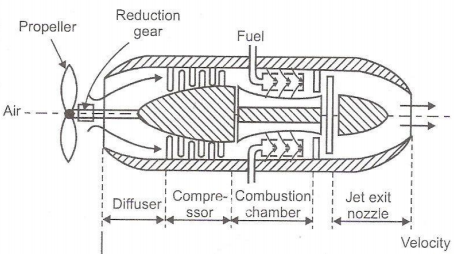

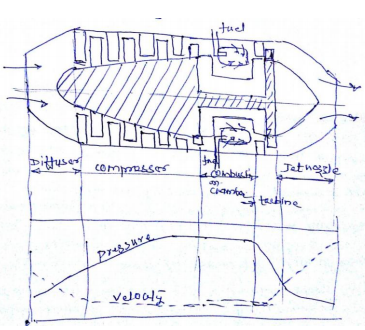

Question:

Explain the working principle of turbojet with neat sketch. Answer:

|

4 |

view |

| Q 3 d ) |

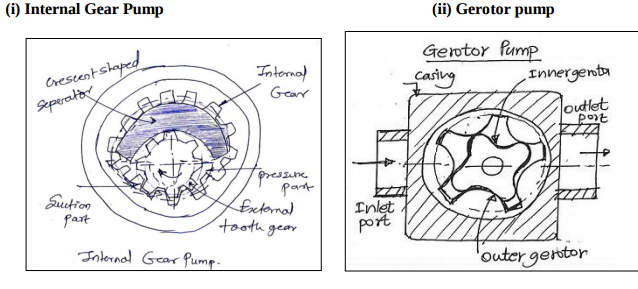

Question:

Draw neat labelled sketch of (i) Internal gear pump (ii) Gerotor pump Answer:

|

4 |

view |

| Q 3 e ) |

Question:

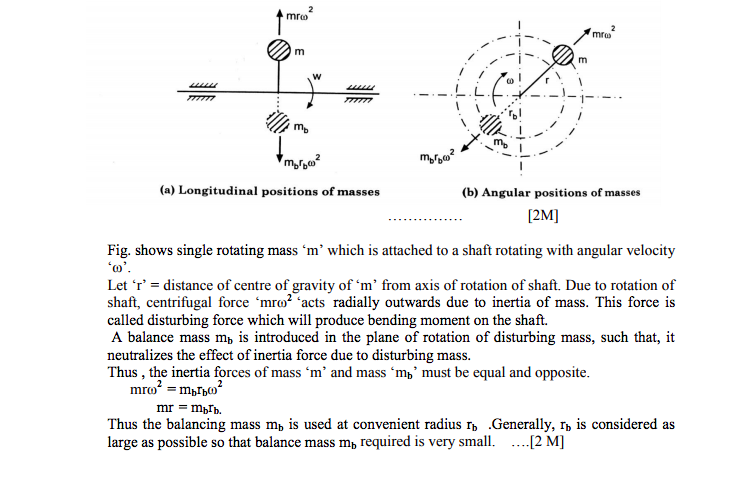

Write the procedure for balancing of a single rotating mass by single masses rotating in the same plane. Answer:

|

4 |

view |

| Q 3 e ) |

Question:

State the advantages of closed cycle gas turbine over open cycle gas turbine (any four). Answer:

|

4 |

view |

| Q 3 e ) |

Question:

What is FRL ? State the function of each component of FRL. Answer:

|

4 |

view |

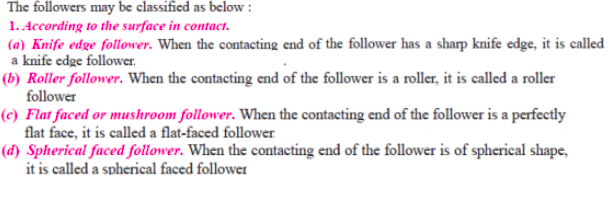

| Q 3 f ) |

Question:

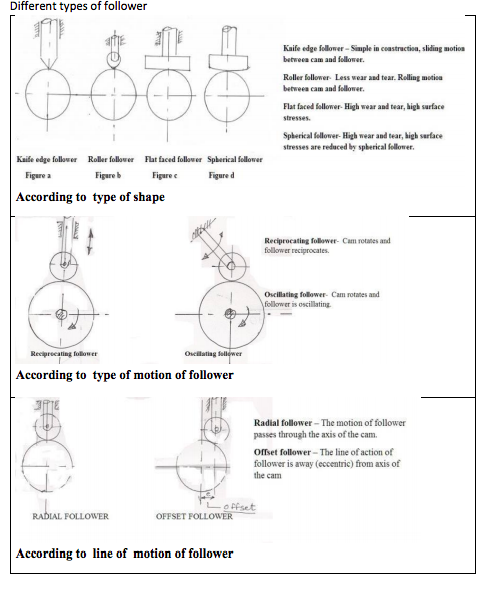

Give detailed classification of followers. Answer:

|

4 |

view |

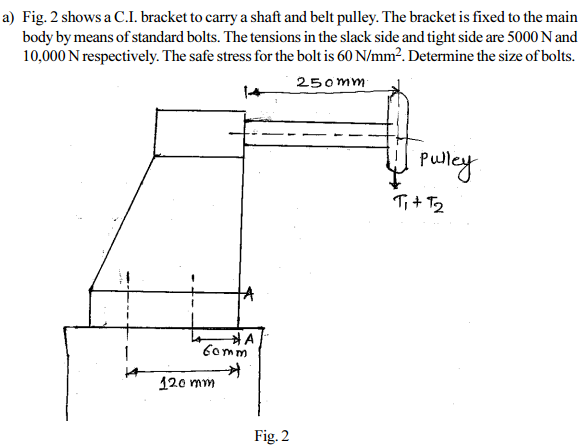

| Q 4 a ) |

Question:

Fig 2 show a C.I. bracket to carryof a shaft

Answer:

|

8 |

view |

| Q 4 a ) |

Question:

State advantages and disadvantages of chain drive over belt drive Answer:

|

4 |

view |

| Q 4a)(a) |

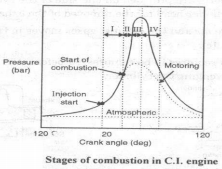

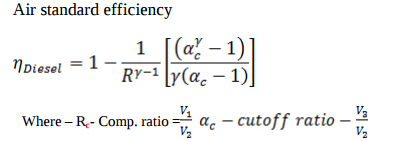

Question:

Define the following w.r.to. I.C. engine. Answer:

|

4 |

view |

| Q 4a)(a) |

Question:

State the four merits and demerits of using a rubber hose in pneumatic circuit. Answer:

|

4 |

view |

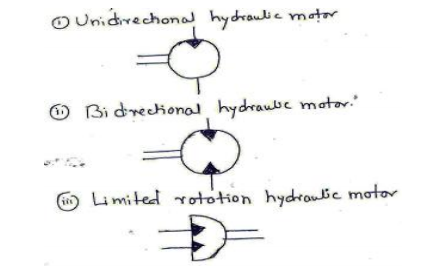

| Q 4a)(b) |

Question:

List any four applications of pneumatic rotary actuator. Draw the symbol for variable speed bidirectional air motor. Answer:

|

4 |

view |

| Q 4a)(b) |

Question:

Explain the term swept volume (V s ) w.r.to. Answer:

|

4 |

view |

| Q 4a)(c) |

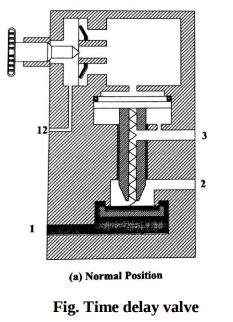

Question:

What is the Function of Time Delay valve? Answer:

|

4 |

view |

| Q 4a)(c) |

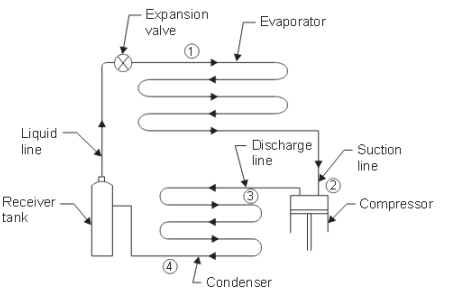

Question:

Draw a neat block diagram of vapour compression cycle. Show the direction of flow ofrefrigerant. Answer:

|

4 |

view |

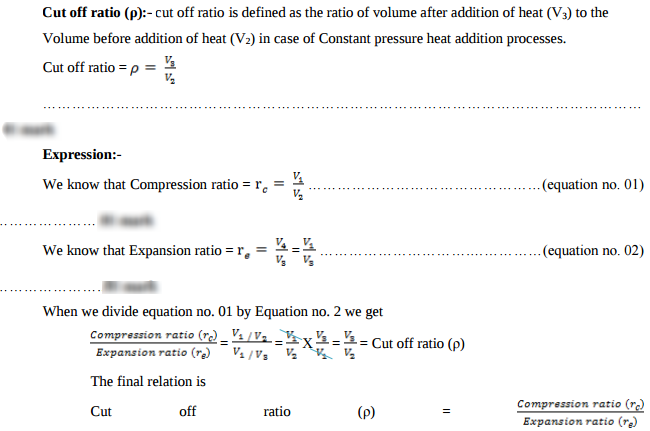

| Q 4a)(d) |

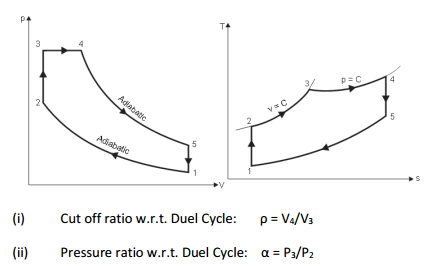

Question:

Explain w.r.to. dual cycle i) cutoff ratio ii) pressure ratio. Answer:

|

4 |

view |

| Q 4a)(d) |

Question:

Draw speed control pneumatic circuit for bi-directional air motor. Answer:

|

4 |

view |

| Q 4 b ) |

Question:

A helical compeersion imperssion speraing

Answer:

|

8 |

view |

| Q 4 b ) |

Question:

Justify that slider crank mechanism is a modification of the basic four bar mechanism with neat sketch. Answer:

|

4 |

view |

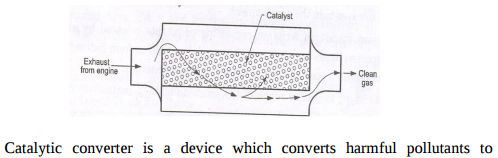

| Q 4b)(a) |

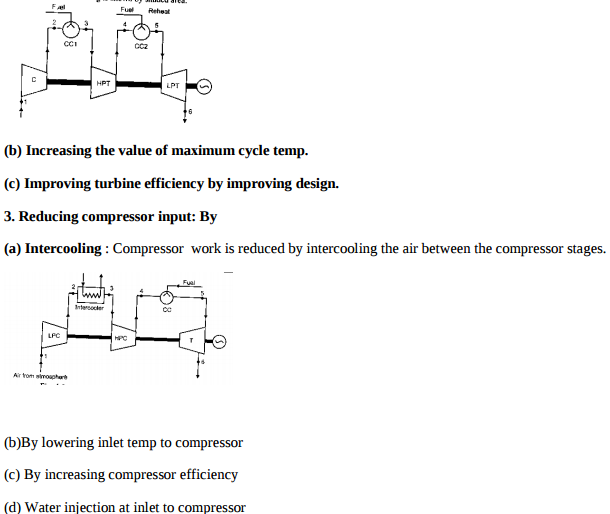

Question:

What is meant by catalytic converter ? Briefly explain with the help of neat sketch. Answer:

|

6 |

view |

| Q 4b)(a) |

Question:

Explain variable displacement axial piston pump with neat sketch. Answer:

|

6 |

view |

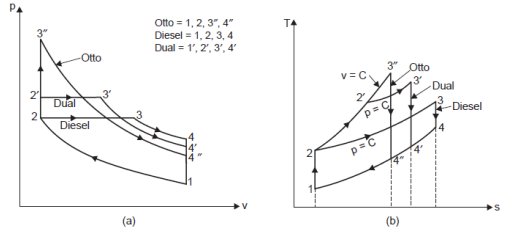

| Q 4b)(b) |

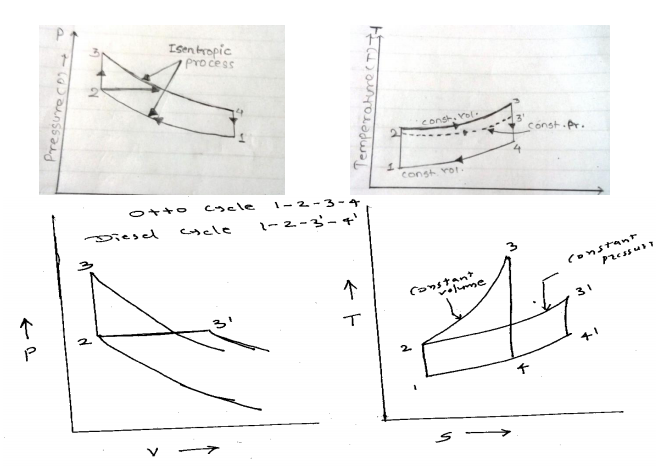

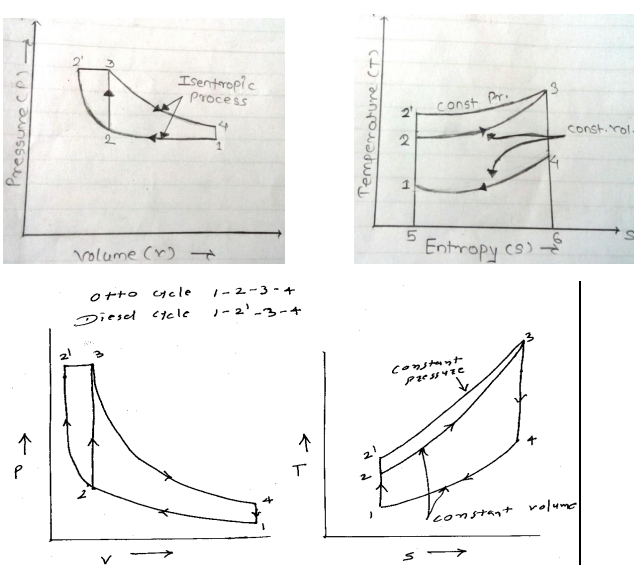

Question:

Draw superimposed p-v diagram of Otto cycle, Diesel cycle and Dual cycle to compare Answer:

|

6 |

view |

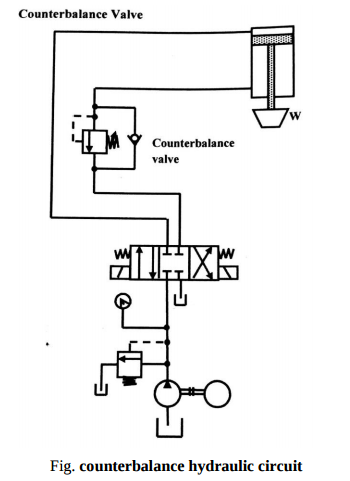

| Q 4b)(b) |

Question:

Explain working of counterbalance hydraulic circuit with neat diagram. Answer:

|

6 |

view |

| Q 4 c ) |

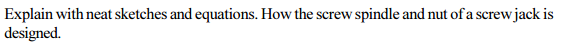

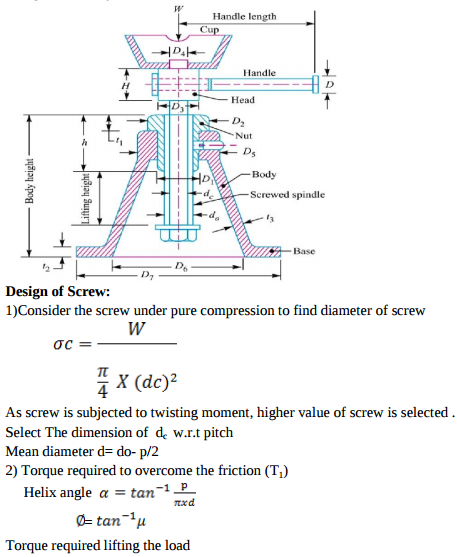

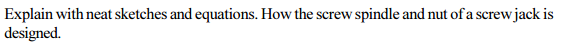

Question:

Design of screw jack

Answer:

|

8 |

view |

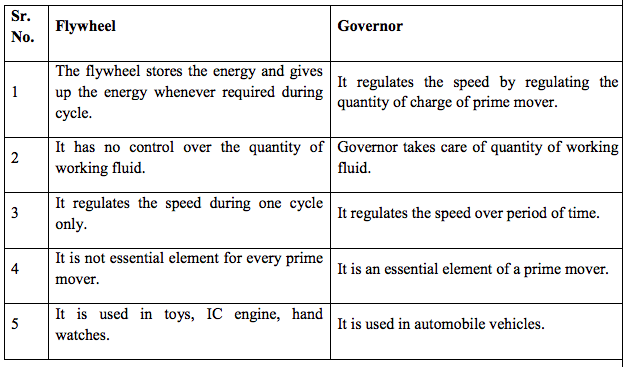

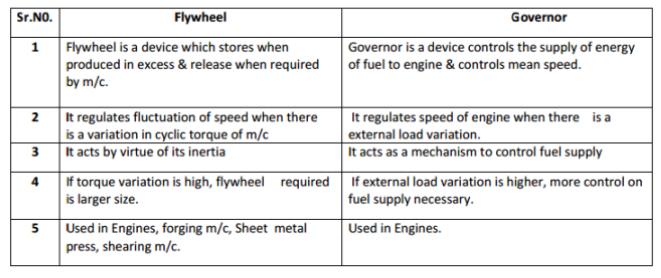

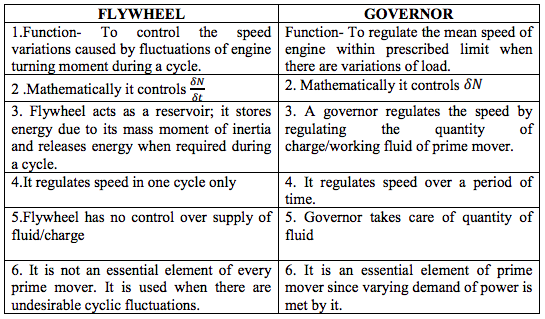

| Q 4 c ) |

Question:

Compare flywheel and governor. Answer:

|

4 |

view |

| Q 4 d ) |

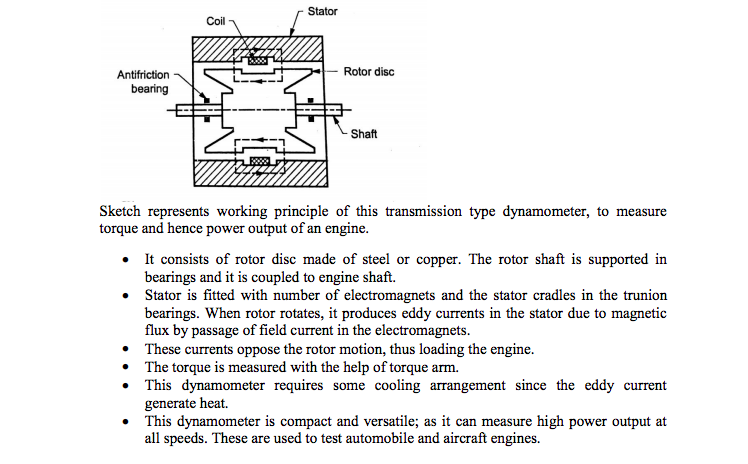

Question:

Explain with neat sketch construction and working of eddy current dynamometer. Answer:

|

4 |

view |

| Q 4 e ) |

Question:

A flat foot step bearing 225 mm in diameter supports a load of 7500 N. If the co-efficient of friction is 0.09 and the shaft rotates at 600 rpm, calculate the power lost in friction. Answer:

|

4 |

view |

| Q 4 f ) |

Question:

Four masses attached to a shaft and their respective radii of rotation are given as : Answer:

|

4 |

view |

| Q 5 a ) |

Question:

Parallel and transverse Weld

Answer:

|

8 |

view |

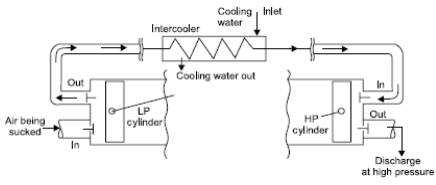

| Q 5 a ) |

Question:

State the methods to improve efficiency of air compressor. Explain two stage air compressor with perfect intercooling with neat sketch. Answer:

|

8 |

view |

| Q 5 a ) |

Question:

The crank of a slider crank mechanism rotates clockwise at a constant speed Answer:

|

8 |

view |

| Q 5 a ) |

Question:

List different types of pressure regulator valves ? Explain any one with neat sketch. Answer:

|

8 |

view |

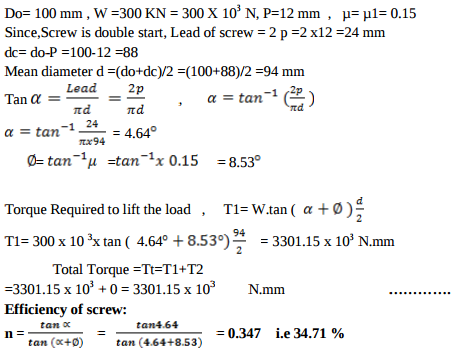

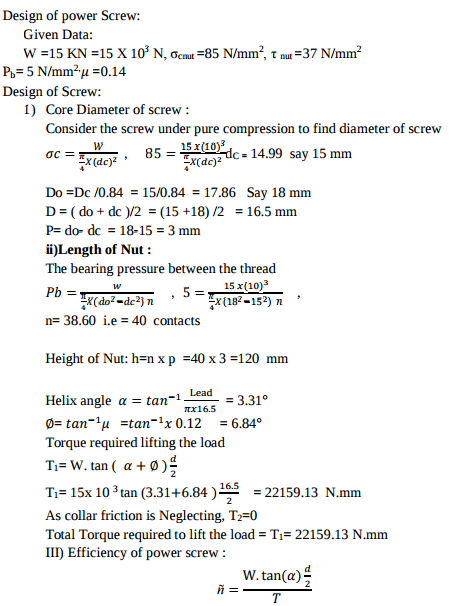

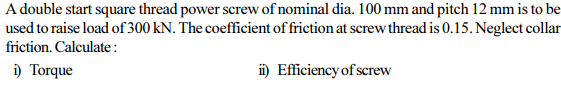

| Q 5 b ) |

Question:

Power Screw: Given Data

Answer:

|

8 |

view |

| Q 5 b ) |

Question:

State the applications of reciprocating compressor and rotary compressor (4 each). Answer:

|

8 |

view |

| Q 5 b ) |

Question:

Draw the profile of a cam to raise a valve with S.H.M. through 40 mm in Answer:

|

8 |

view |

| Q 5 b ) |

Question:

Develop a pneumatic circuit for operation of two DA cylinders such that one operates after other using travel dependant sequencing. Answer:

|

8 |

view |

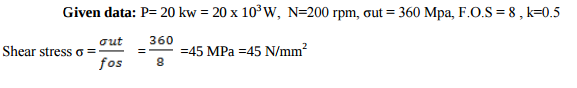

| Q 5 c ) |

Question:

Hollow shaft:

Answer:

|

8 |

view |

| Q 5 c ) |

Question:

List out different pollutants in exhaust gases of petrol and diesel engine ? Briefly explain theireffects on human beings and environments (atleast four). Answer:

|

8 |

view |

| Q 5 c ) |

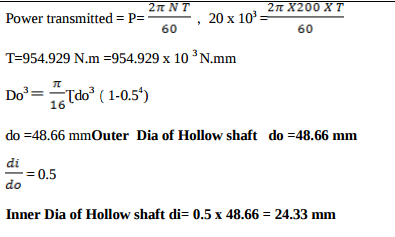

Question:

Two pulley, one 450 mm diameter and the other 200 mm diameter are on Answer:

|

8 |

view |

| Q 5 c ) |

Question:

Explain pneumatic impulse circuit with neat sketch. Answer:

|

8 |

view |

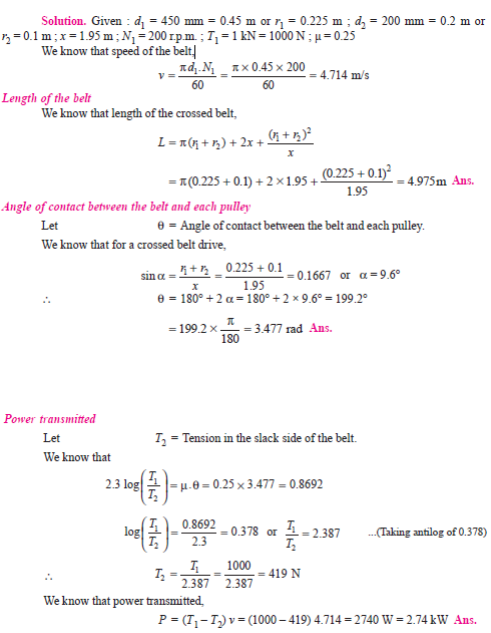

| Q 6 a ) |

Question:

Effect of Keyway on strength of shaft

Answer:

|

8 |

view |

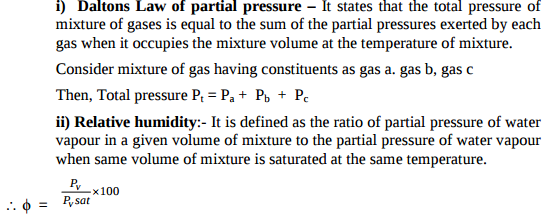

| Q 6 a ) |

Question:

Explain the following terms :- i) Daltons law of partial pressures ii) Relative humidity Answer:

|

4 |

view |

| Q 6 a ) |

Question:

State at least four advantages and disadvantages of pneumatic systems. Answer:

|

4 |

view |

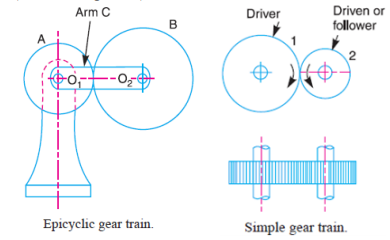

| Q 6a)(i) |

Question:

State types of gear train and explain any one. Answer:

|

8 |

view |

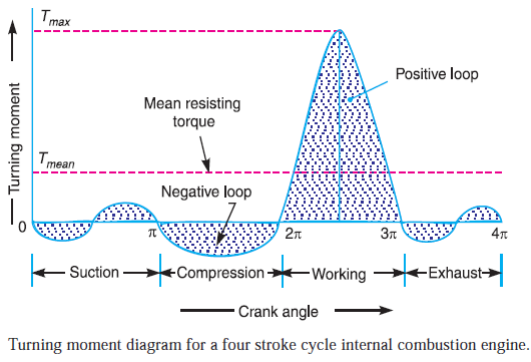

| Q 6a)(ii) |

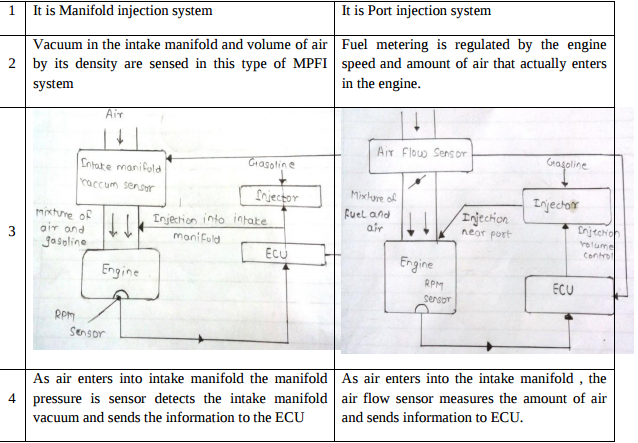

Question:

Draw turning moment diagram for single cylinder four stroke I.C. Answer:

|

8 |

view |

| Q 6 b ) |

Question:

Sketch a psychrometric chart and show the following properties of air on it. i) DBT lines ii) WBT lines iii) Specific volume lines iv) Relative humidity lines Answer:

|

4 |

view |

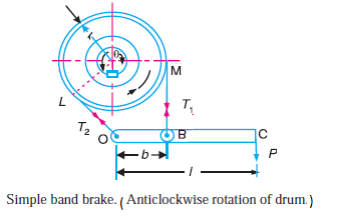

| Q 6 b ) |

Question:

A simple band brake is operated by lever 40 cm long. The brake drum Answer:

|

8 |

view |

| Q 6 b ) |

Question:

Draw symbol of unloading valve and sequence valve. Answer:

|

4 |

view |

| Q 6b)(i) |

Question:

Identyfiy the metrial and its compotion A) X10Cr 18 Ni9 Mo 4 Si 2 B) XT72W18Cr4V1:

Answer:

|

8 |

view |

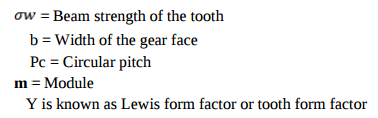

| Q 6b)(ii) |

Question:

Design consideration while designing the spur Gear Answer:

|

8 |

view |

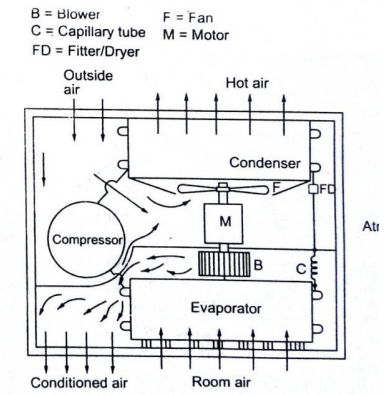

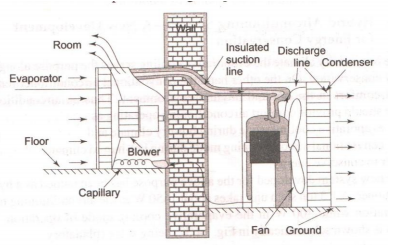

| Q 6 c ) |

Question:

Draw only a neat labelled sketch of window air-conditioner. Answer:

|

4 |

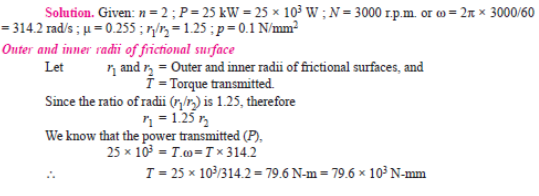

view |

| Q 6 c ) |

Question:

A single plate clutch, effective on both sides, is required to transmit 25 kW at Answer:

|

8 |

view |

| Q 6 c ) |

Question:

Enlist the hydraulic oil manufacturer’s in India. Answer:

|

4 |

view |

| Q 6c)(i) |

Question:

State any four area of Application of spring: Answer:

|

4 |

view |

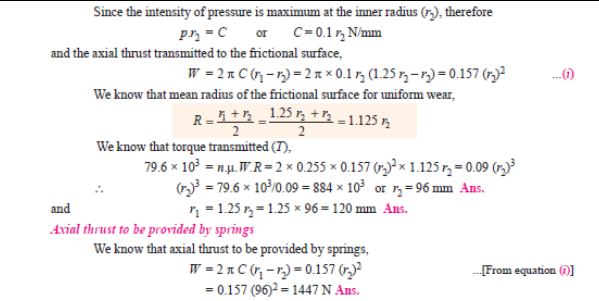

| Q 6c)(ii) |

Question:

State of the Classification of shaft coupling : Answer:

|

8 |

view |

| Q 6 d ) |

Question:

Enlist different uses of compressed air. Answer:

|

4 |

view |

| Q 6 d ) |

Question:

Enlist applications of hydraulic system. Answer:

|

4 |

view |

| Q 6 e ) |

Question:

State the applications of gas turbine (any four). Answer:

|

4 |

view |

| Q 6 e ) |

Question:

Explain pneumatic circuit for speed control of single acting cylinder with neat sketch. Answer:

|

4 |

view |

| Que.No | Question/Problem | marks | Link | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

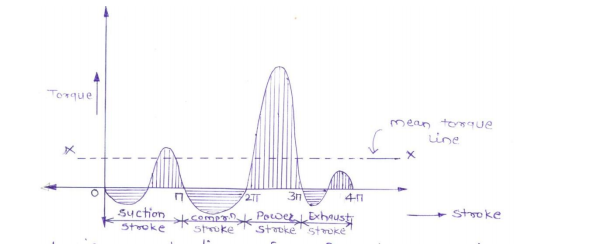

| Q a)(ii) |

Question:

Explain single cylinder 4-stroke I.C. engine using turning moment diagram. Answer:

|

4 |

view | |||||||||||||||

| Q 1a)(a) |

Question:

Represent ‘Brayton Cycle’ on P-V and T-S diagram. Answer:

|

4 |

view | |||||||||||||||

| Q 1a)(b) |

Question:

Define following terms w.r.t. air compressor. i) FAD ii) Compression ratio. Answer:

|

4 |

view | |||||||||||||||

| Q 1a)(c) |

Question:

Enlist different uses of compressed air. Answer:

|

4 |

view | |||||||||||||||

| Q 1a)(d) |

Question:

Draw ‘Valve timing diagram for 4-stroke cycle diesel engine. Answer:

|

4 |

view | |||||||||||||||

| Q 1a)(i) |

Question:

Enlist the types of constrained motion. Draw a label sketch of any one Answer:

(i)Completely constrained motion. (ii)Incompletely constrained motion. (iii)Successfully constrained motion. |

2 |

view | |||||||||||||||

| Q 1a)(ii) |

Question:

Define (i) Pressure angle (ii) Pitch point related to cam. Answer:

(ii) Pitch point: It is point on pitch curve having the maximum pressure angle. |

2 |

view | |||||||||||||||

| Q 1a)(iii) |

Question:

How are drives classified? Answer:

(i) Belt drives. (ii) Chain drives. (iii) Rope. (iv) Gear drives. |

2 |

view | |||||||||||||||

| Q 1a)(iv) |

Question:

Define: Answer:

Mathematically, C s = (N 1 – N 2 ) /N Where, N 1 = maximum speed in rpm; Mathematically, Ce = Maximum fluctuation of energy/ Work done per cycle. |

2 |

view | |||||||||||||||

| Q 1a)(v) |

Question:

Write any two disadvantages of chain drive. Answer:

1. Manufacturing cost of chains is relatively high. 2. The chain drive needs accurate mounting and careful maintenance. 3. High velocity fluctuations especially when unduly stretched. 4. Chain operations are noisy as compared to belts. |

2 |

view | |||||||||||||||

| Q 1a)(vi) |

Question:

Draw line diagram of porter governor Answer:

|

2 |

view | |||||||||||||||

| Q 1a)(vii) |

Question:

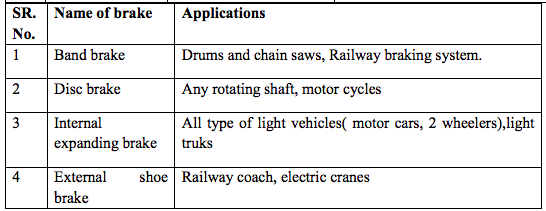

State the application of (i) Disc brake (ii) Internal expanding brake Answer:

(ii) Internal expanding brake: Used in motor cars, light trucks, two wheelers etc. |

2 |

view | |||||||||||||||

| Q 1a)(viii) |

Question:

Why is balancing of rotating parts necessary for high speed engines? Answer:

is, therefore, very essential that all the rotating and reciprocating parts should be completely balanced as far as possible. If these parts are not properly balanced, the dynamic forces are set up. These forces not only increase the loads on bearings and stresses in the various members, but also produce unpleasant and even dangerous vibrations. The balancing of unbalanced forces is caused by rotating masses, in order to minimize pressure on the main bearings when an engine is running. |

2 |

view | |||||||||||||||

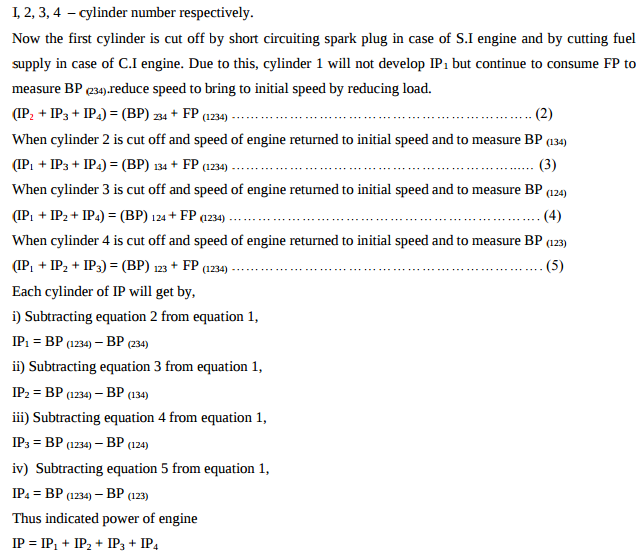

| Q 1b)(a) |

Question:

Explain in brief, how ‘Morse test’ is carried out ? Answer:

|

6 |

view | |||||||||||||||

| Q 1b)(b) |

Question:

Explain with neat sketch the constructional features of ‘Three Way Catalytic Converter’. Answer:

|

6 |

view | |||||||||||||||

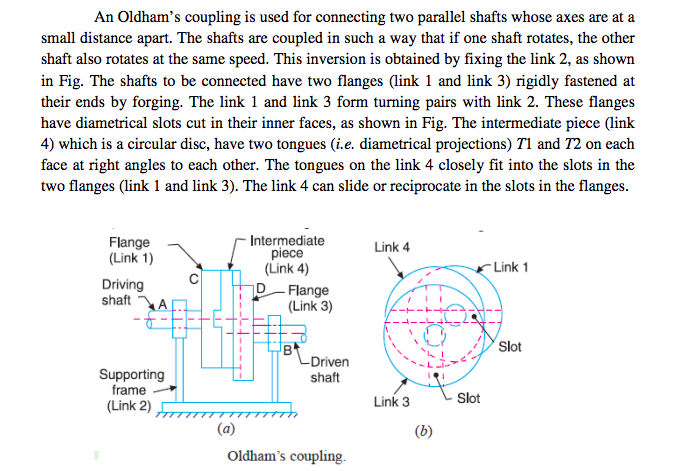

| Q 1b)(i) |

Question:

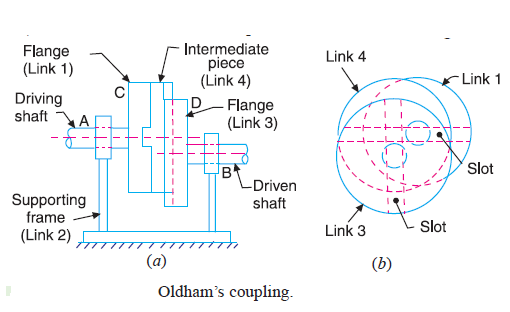

State inversions of double slider crank chain. Explain Oldham's coupling with neat sketch Answer:

i.Scotch Yoke mechanism. ii.Oldham’s coupling. iii. Elliptical trammel. An Oldham’s coupling is used for connecting two parallel shafts whose axes are at a small distance apart. The shafts are coupled in such a way that if one shaft rotates, the other shaft also rotates at the same speed. This inversion is obtained by fixing the link 2, as shown in Fig. The shafts to be connected have two flanges (link 1 and link 3) rigidly fastened at their ends by forging. The link 1 and link 3 form turning pairs with link 2. These flanges have diametrical slots cut in their inner faces, as shown in Fig. The intermediate piece (link 4) which is a circular disc, have two tongues (i.e. diametrical projections) T1 and T2 on each face at right angles to each other. The tongues on the link 4 closely fit into the slots in the two flanges (link 1 and link 3). The link 4 can slide or reciprocate in the slots in the flanges. (link 4) to rotate at the same angle through\ which the flange has rotated, and it further rotates the flange D (link 3) at the same angle and thus the shaft B rotates. Hence links 1, 3 and 4 have the same angular velocity at every instant. A little consideration will show that there is a sliding motion between the link 4 and each of the other links 1 and 3. |

4 |

view | |||||||||||||||

| Q 1b)(ii) |

Question:

Explain: (i) Uniform pressure theory. (ii) Uniform wear theory in clutches and bearing. Answer:

When the mating component in clutch, bearing are new, then the contact between surfaces may be good over the whole surface. It means that the pressure over the rubbing surfaces is uniform distributed. This condition is not valid for old clutches, bearings because mating surfaces may have uneven friction. The condition assumes that intensity of pressure is same. P = W/A =Constant; where, W= load, A= area (ii) Uniform wear theory in clutches and bearings: parts of the rubbing surfaces will not move with the same velocity. The velocity of rubbing surface increases with the distance from the axis of the rotating element. It means that wear may be different at different radii and rate of wear depends upon the intensity of pressure (P) and the velocity of rubbing surfaces (V). It is assumed that the rate of wear is proportional to the product of intensity of pressure and velocity of rubbing surfaces. This condition assumes that rate of wear is uniform; P*r = Constant; where, P = intensity of pressure, r = radius of rotation. |

4 |

view | |||||||||||||||

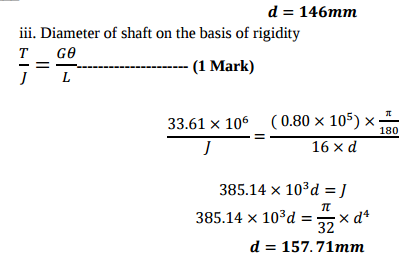

| Q 1b)(ii) |

Question:

The shaft running at 125 r.p.m. transmits 440 kW. Find the diameter of shaft (d) if allowable shear stress in shaft material is 55 N/mm2 and the angle of twist must not be more than 1 on a length of 16(d). The modulus of rigidity G = 0.80 105 N/mm Answer:

|

6 |

view | |||||||||||||||

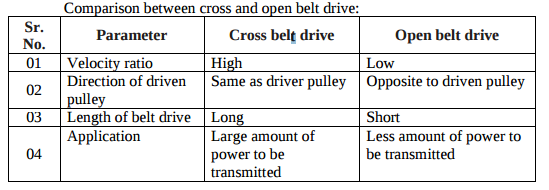

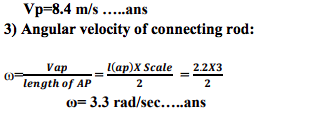

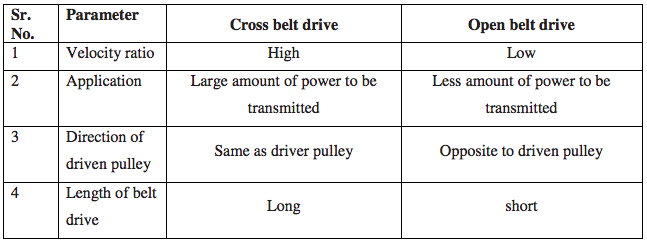

| Q 1b)(iii) |

Question:

Compare cross belt drive and open belt drive on the basis of: (i) Velocity ratio. (ii) Direction of driven pulley. (iii) Length of belt drives (iv) Application. Answer:

|

4 |

view | |||||||||||||||

| Q 1b)(l) |

Question:

What is stress concentration ? State the remedial measures to control the effect of stress concentration with neat sketches Answer:

|

6 |

view | |||||||||||||||

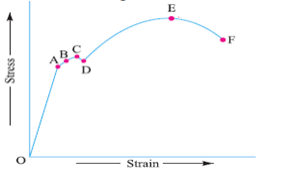

| Q 1 i ) |

Question:

Draw stress-strain diagram for ductile material stating salient points Answer:

|

4 |

view | |||||||||||||||

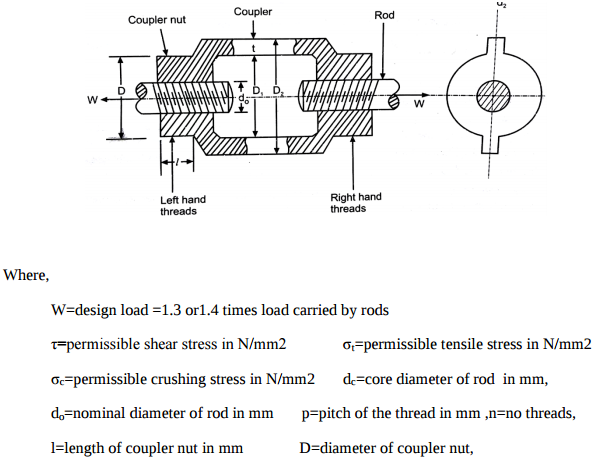

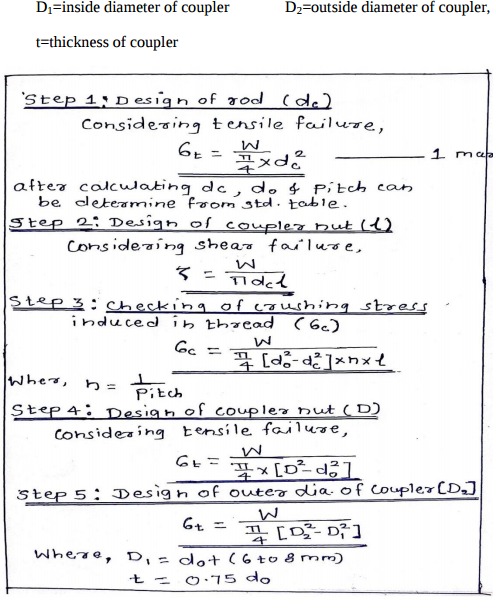

| Q 1 ii ) |

Question:

Write the design procedure for turn buckle. (Any four steps) Answer:

|

4 |

view | |||||||||||||||

| Q 1 iii ) |

Question:

State any four factors to be considered while selecting the coupling. Answer:

|

4 |

view | |||||||||||||||

| Q 1 iv ) |

Question:

Why square threads are preferred over V-thread for power transmission ? Answer:

|

4 |

view | |||||||||||||||

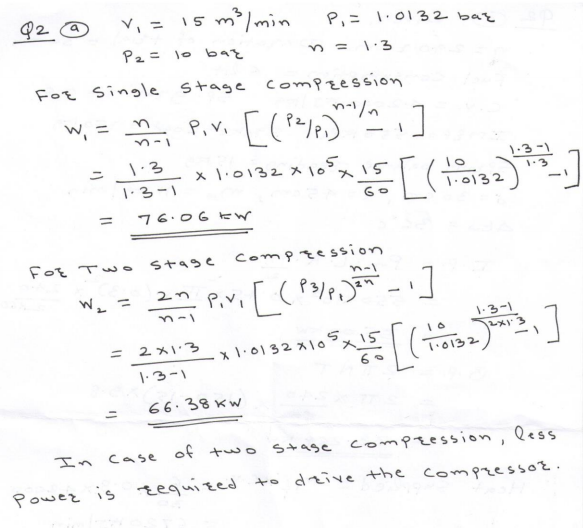

| Q 2 a ) |

Question:

It is desired to compress 15 m3 of air per minute from 1.0132 bar to 10 bar. Calculate minimum power required to drive the compressor having two stages and compared it the power required for single stage compression. Assume value of index for compression process to be 1.3 for both cases also assume the condition for maximum efficiency Answer:

|

8 |

view | |||||||||||||||

| Q 2 a ) |

Question:

Draw a labeled sketch of quick return mechanism of shaper and explain its working? Answer:

|

4 |

view | |||||||||||||||

| Q 2a)(i) |

Question:

State any four factors that govern ‘factor of safety’. Answer:

|

8 |

view | |||||||||||||||

| Q 2a)(ii) |

Question:

Why taper is provided on cotter ? State recommended values of taper. Answer:

|

8 |

view | |||||||||||||||

| Q 2 b ) |

Question:

Draw neat sketch showing the details of cotter joint. State strength equations for each component with suitable failure cross-sectional area. Answer:

|

8 |

view | |||||||||||||||

| Q 2 b ) |

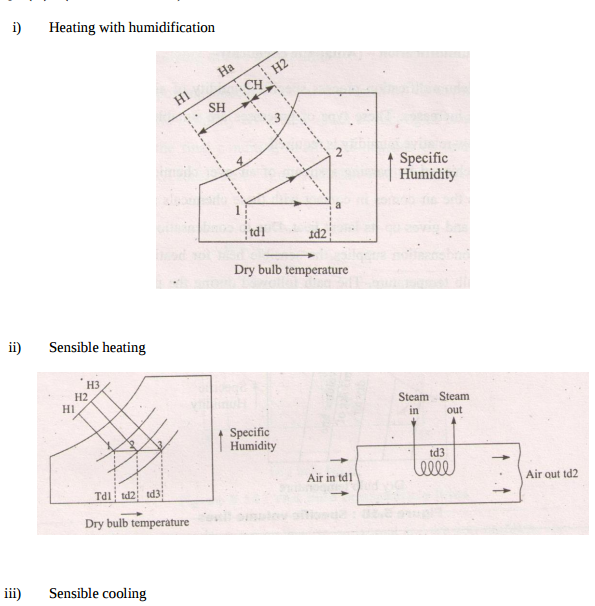

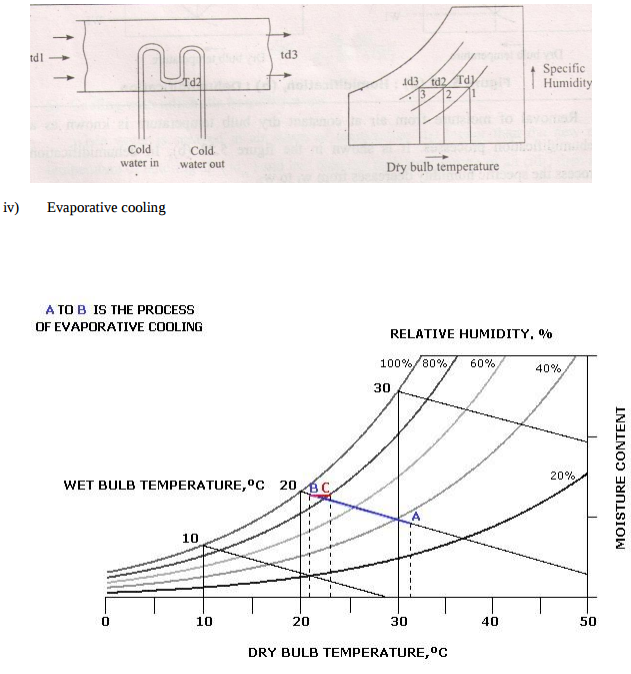

Question:

Represent following processes on Psychrometric chart. i) Heating with humidification ii) Sensible heating. iii) Sensible cooling iv) Evaporative cooling. Answer:

|

8 |

view | |||||||||||||||

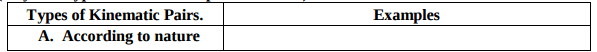

| Q 2 b ) |

Question:

What are the types of kinematic pair ? Give its examples. Answer:

|

4 |

view | |||||||||||||||

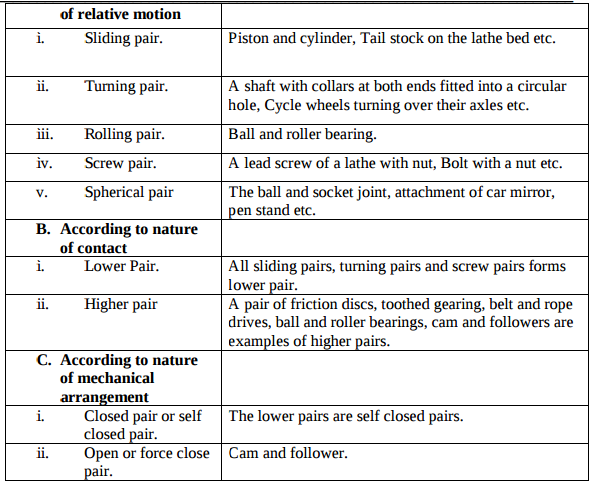

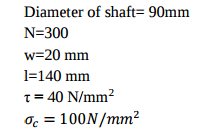

| Q 2 c ) |

Question:

A belt pulley is fastened to a 90 mm diameter shaft running at 300 r.p.m. by means of a key 20 mm wide and 140 mm long. Allowable stress for the shaft and key material are 40 N/mm2 in shear and 100 N/mm2 in crushing. Find the power transmitted and the depth of the key required. Answer:

|

8 |

view | |||||||||||||||

| Q 2 c ) |

Question:

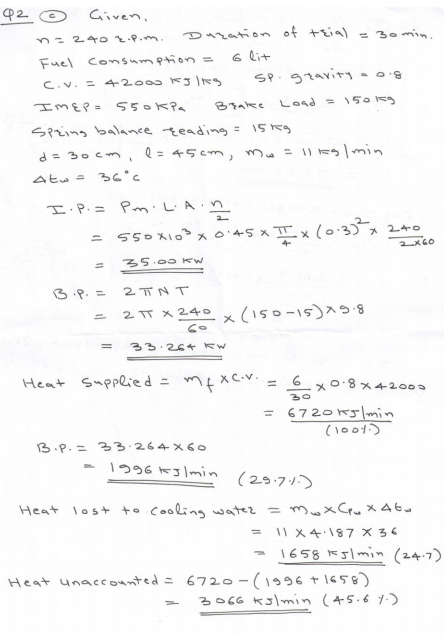

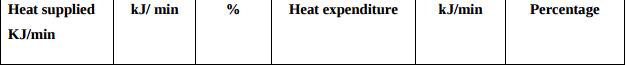

Following observations were made during a trial on 4-stroke, single cylinder engine running at 240 rpm having brake wheel diameter 1.5 meter. Duration of trial 30 min. Fuel consumption 6 liter C.V. of fuel 42000 kJ/kg Sp. gravity 0.8 IMEP 550 kPa Brake load 150 kg Spring balance reading 15 kg Cylinder diameter 30 cm Stroke length 45 cm Jacket cooling water 11 kg/min Temp. rise in jacket water 36°C Determine : i) I.P. and B.P. ii) Heat balance sheet on percentage basis. Answer:

|

8 |

view | |||||||||||||||

| Q 2 c ) |

Question:

Define linear velocity, angular velocity, absolute velocity and state the relation between linear velocity and angular velocity. Answer:

|

4 |

view | |||||||||||||||

| Q 2 d ) |

Question:

Explain the Klein's construction to determine velocity and acceleration of single slider crank mechanism. Answer:

|

4 |

view | |||||||||||||||

| Q 2 e ) |

Question:

Draw neat sketch of radial cam with follower and show on it (i) Base circle. (ii) Pitch point. (iii) Prime Circle. (iv) Cam profile Answer:

|

4 |

view | |||||||||||||||

| Q 2 f ) |

Question:

A shaft runs at 80 rpm & drives another shaft at 150 rpm through belt drive. The diameter of the driving pulley is 600 mm. Determine the diameter of the driven pulley in the following cases: (i) Taking belt thickness as 5 mm. (ii) Assuming for belt thickness 5 mm and total slip of 4%. Answer:

|

4 |

view | |||||||||||||||

| Q 3 a ) |

Question:

State any four advantages of standardization. Answer:

|

4 |

view | |||||||||||||||

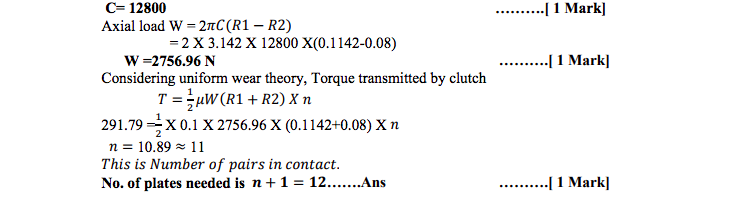

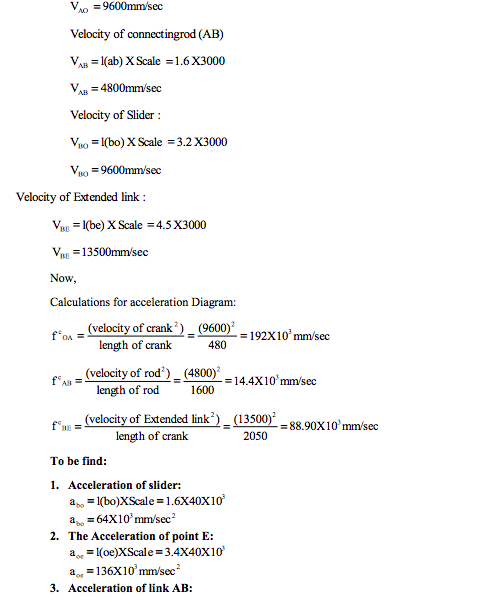

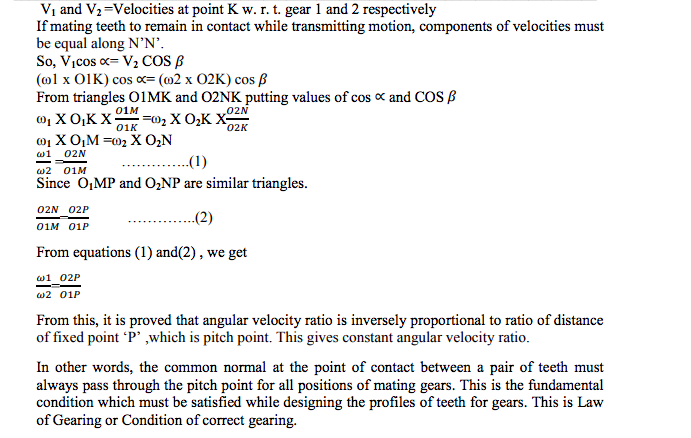

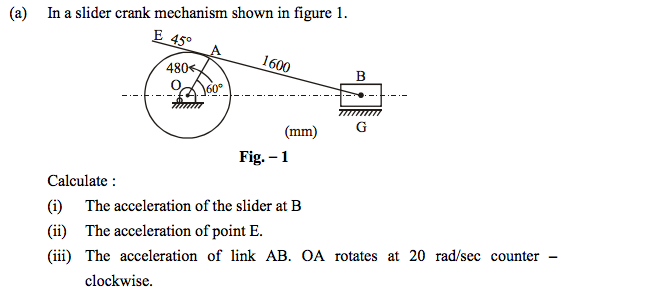

| Q 3 a ) |

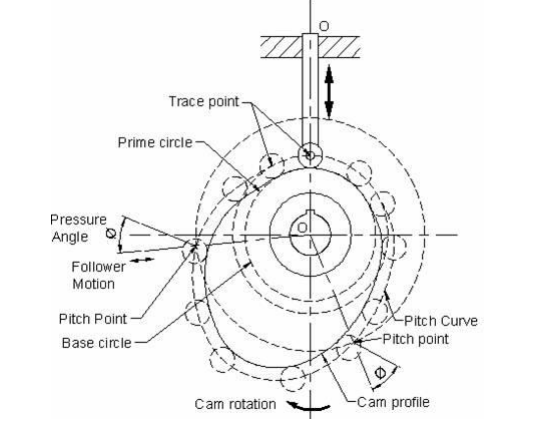

Question:

In a slider-crank mechanism, the crank is 480 mm long and rotates at 20 rad/sec in the counter-clockwise direction. The length of the connecting rod is 1600 mm. when the crank turns 60 from the inner-dead centre. Determine the velocity of the slider by relative velocity method. Answer:

|

4 |

view | |||||||||||||||

| Q 3 b ) |

Question:

Draw a neat sketch of bell crank lever. Enlist steps in designing the bell crank lever Answer:

|

4 |

view | |||||||||||||||

| Q 3 b ) |

Question:

Classify gas turbine on the basis of i) working cycle ii) application iii) cycle of operation iv) fuel used Answer:

|

4 |

view | |||||||||||||||

| Q 3 b ) |

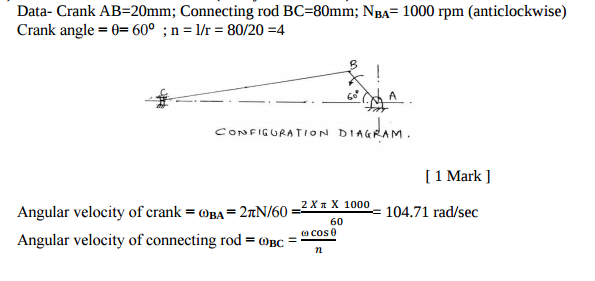

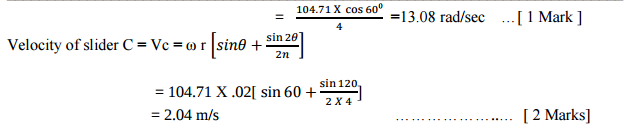

Question:

In a slider crank mechanism, crank AB = 20 mm & connecting rod BC = 80 mm. Crank AB rotates with uniform speed of 1000 rpm in anticlockwise direction. Find (i) Angular velocity of connecting rod BC (ii) Velocity of slider C. When crank AB makes an angle of 60 degrees with the horizontal. Draw the configuration diagram also. Use analytical method. Answer:

|

4 |

view | |||||||||||||||

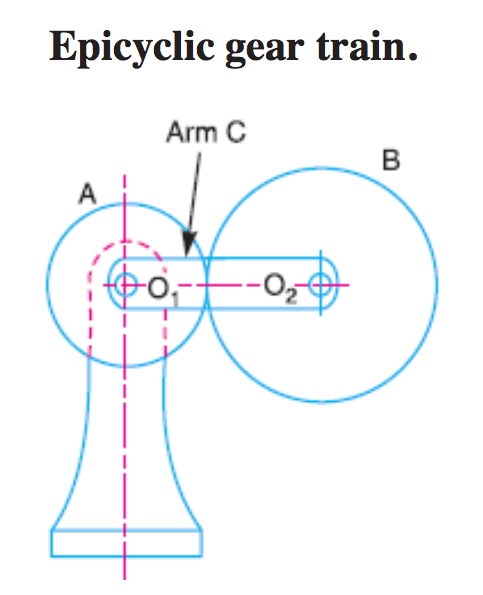

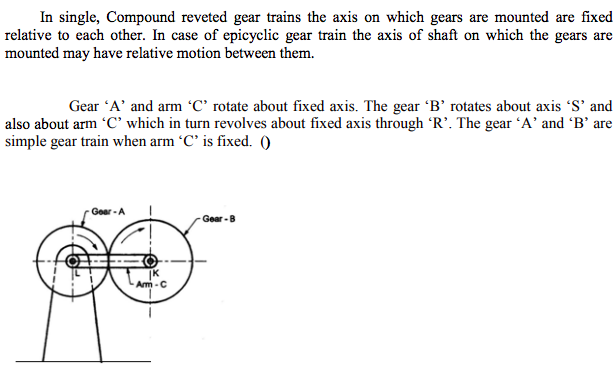

| Q 3 c ) |

Question:

Explain epicyclic gear train with neat sketch. Answer:

|

4 |

view | |||||||||||||||

| Q 3 c ) |

Question:

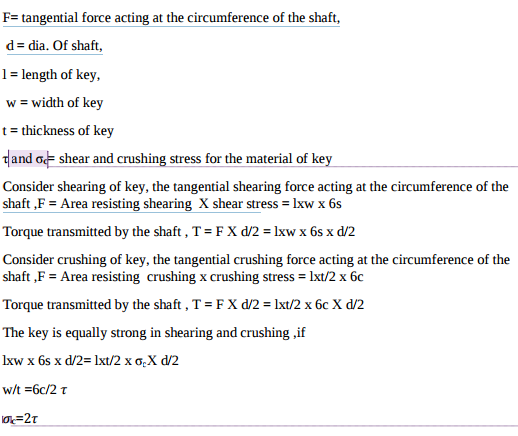

Prove that, for a square key, the permissible crushing stress is twice the permissible shear stress. Answer:

|

4 |

view | |||||||||||||||

| Q 3 c ) |

Question:

Enlist the four effects of subcooling on the performance of V.C.C. refrigeration cycle. Answer:

|

4 |

view | |||||||||||||||

| Q 3 d ) |

Question:

Draw a labelled sketch of multiplate clutch and state its applications. Answer:

|

4 |

view | |||||||||||||||

| Q 3 d ) |

Question:

Why a coupling should be placed as close to a bearing as possible Answer:

|

4 |

view | |||||||||||||||

| Q 3 d ) |

Question:

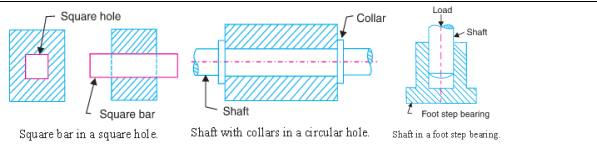

What is ‘Scavenging’ ? List any two types of ‘scavenging’. Answer:

|

4 |

view | |||||||||||||||

| Q 3 e ) |

Question:

Write the procedure of balancing single rotating mass when it balance mass is rotating in the same plane as that of disturbing mass. Answer:

|

4 |

view | |||||||||||||||

| Q 3 e ) |

Question:

Describe ‘bolt of uniform strength’ with neat sketch Answer:

|

4 |

view | |||||||||||||||

| Q 3 e ) |

Question:

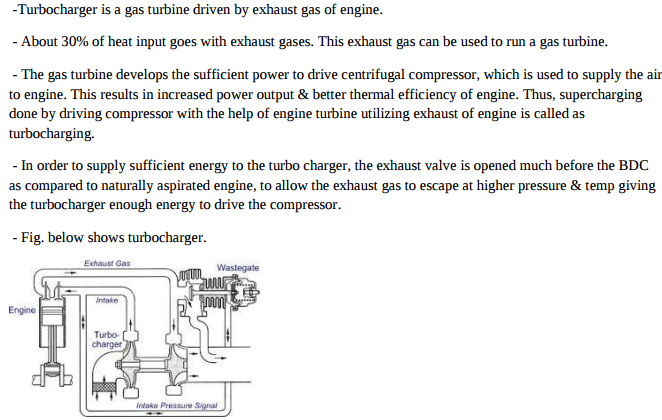

Explain in brief the importance of ‘Super Charging’. Answer:

|

4 |

view | |||||||||||||||

| Q 3 f ) |

Question:

What are the different types of follower motion ? Also draw displacement diagram for uniform velocity. Answer:

|

4 |

view | |||||||||||||||

| Q 4a)(a) |

Question:

Explain in brief the constructional features of MPFI engine Answer:

|

4 |

view | |||||||||||||||

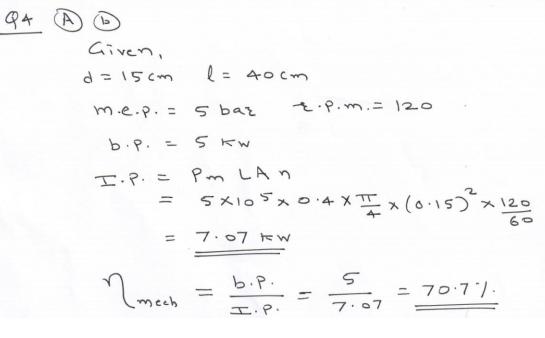

| Q 4a)(b) |

Question:

An engine has piston diameter 15 cm, length of stroke 40 cm and mean effective pressure 5 bar. Engine makes 120 power strokes per minute. Find mechanical efficiency if brake power is 5 kW. Answer:

|

4 |

view | |||||||||||||||

| Q 4a)(c) |

Question:

State any four effect of detonation Answer:

|

4 |

view | |||||||||||||||

| Q 4a)(d) |

Question:

Explain the term w.r.t. I.C. engine. i) Mean Effective Pressure (MEP) ii) Cut off ratio. Answer:

|

4 |

view | |||||||||||||||

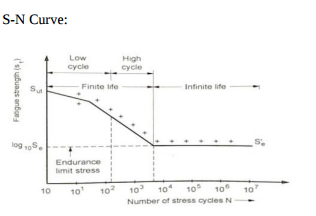

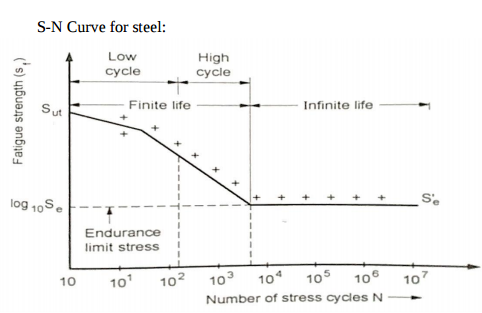

| Q 4a)(i) |

Question:

Define Endurance limit and draw typical S-N curve for steel. Answer:

|

4 |

view | |||||||||||||||

| Q 4a)(ii) |

Question:

State the effect of key-way on the strength of shaft with suitable diagram Answer:

+ + |

4 |

view | |||||||||||||||

| Q 4a)(iii) |

Question:

State any four applications of spring. Answer:

|

4 |

view | |||||||||||||||

| Q 4a)(iii) |

Question:

State any four advantages and disadvantages of welded joints over riveted joints. Answer:

|

4 |

view | |||||||||||||||

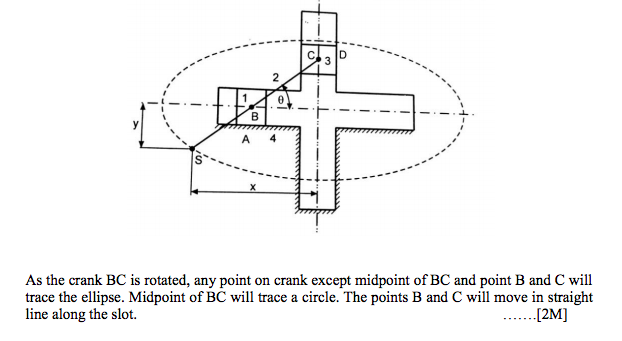

| Q 4 b ) |

Question:

Justify with neat sketch elliptical trammel as an inversion of double slider crank chain. Answer:

|

4 |

view | |||||||||||||||

| Q 4b)(a) |

Question:

Name any four additives used in lubricants ? State their advantages Answer:

|

6 |

view | |||||||||||||||

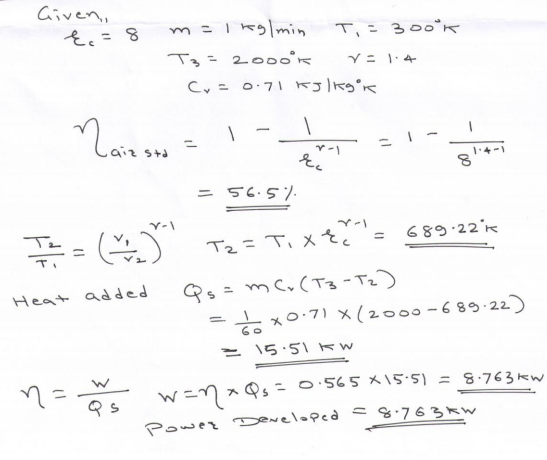

| Q 4b)(b) |

Question:

A petrol engine working on constant volume cycle has compression ratio of 8 and consume 1 kg of air per minute, if minimum and maximum temp. during cycle is 300 °K and 2000 °K respectively. Find power developed by engine. Assume γ = 1.4 and Cv = 0.71 kJ/kg °K. Answer:

|

6 |

view | |||||||||||||||

| Q 4b)(i) |

Question:

Describe the importance of aesthetic considerations in design related to shape, colour and surface finish. Answer:

|

6 |

view | |||||||||||||||

| Q 4b)(ii) |

Question:

State any six design considerations while designing the spur gear Answer:

|

6 |

view | |||||||||||||||

| Q 4 c ) |

Question:

Differentiate between flywheel and governor. Answer:

|

4 |

view | |||||||||||||||

| Q 4 d ) |

Question:

Explain construction and working of eddy current dynamometer. Answer:

|

4 |

view | |||||||||||||||

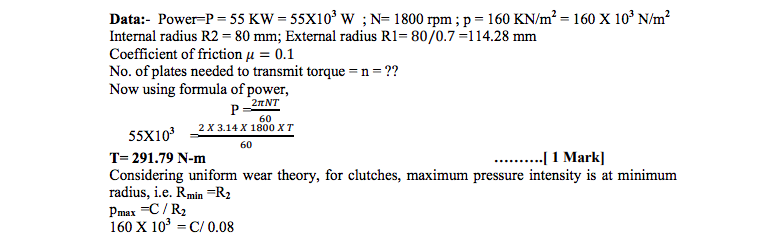

| Q 4 e ) |

Question:

A multiplate disc clutch transmits 55 kW of power at 1800 rpm. Coefficient of friction for the friction surfaces is 0.1. Axial intensity of pressure is not to exceed 160 kN/m2 . The internal radius is 80 mm and is 0.7 times the external radius. Find the number of plates needed to transmit the required torque. Answer:

|

4 |

view | |||||||||||||||

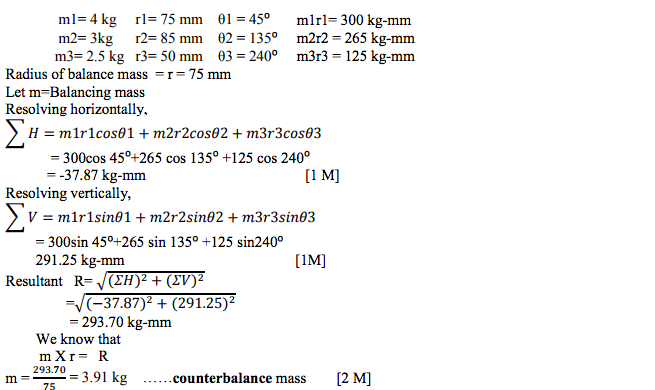

| Q 4 f ) |

Question:

A rotor having the following properties : m1 = 4 kg r1 = 75 mm θ1 = 45o m2 = 3 kg r2 = 85 mm θ2 = 135o m3 = 2.5 kg r3 = 50 mm θ3 = 240o Determine the amount of the countermass at a radial distance of 75 mm required for the static balance. Answer:

|

4 |

view | |||||||||||||||

| Q 5 a ) |

Question:

State and explain Law of Gearing. Answer:

|

4 |

view | |||||||||||||||

| Q 5 a ) |

Question:

Answer:

|

8 |

view | |||||||||||||||

| Q 5 a ) |

Question:

Explain with neat block diagram the working of ‘Vapour Absorbtion Cycle’. Answer:

|

8 |

view | |||||||||||||||

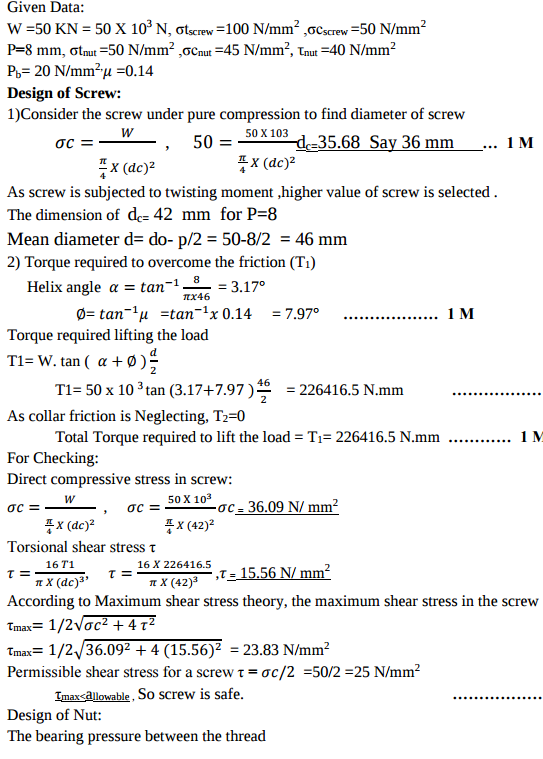

| Q 5 a ) |

Question:

A screw jack is used to lift a load of 50 kN through a maximum lift of 200 mm. The material used for a screw is steel of allowable stresses in tension and compression as 100 N/mm2 and 50 N/mm2 respectively. The pitch of screw is 8 mm. The nut is made of phosphor bronze with allowable stresses as 50 N/mm2 and 45 N/mm2 in tension and crushing. The allowable shear stress for nut material is 40 N/mm2 . The allowable bearing pressure between nut and screw is not to exceed 20 N/mm2 . If the coefficient of friction between screw and nut is 0.14, design the screw and nut Answer:

|

8 |

view | |||||||||||||||

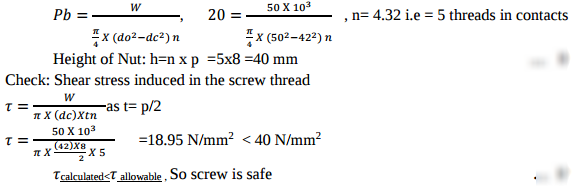

| Q 5 b ) |

Question:

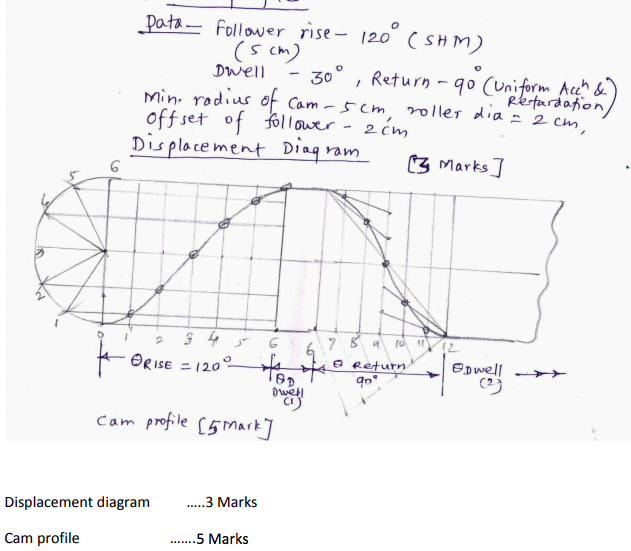

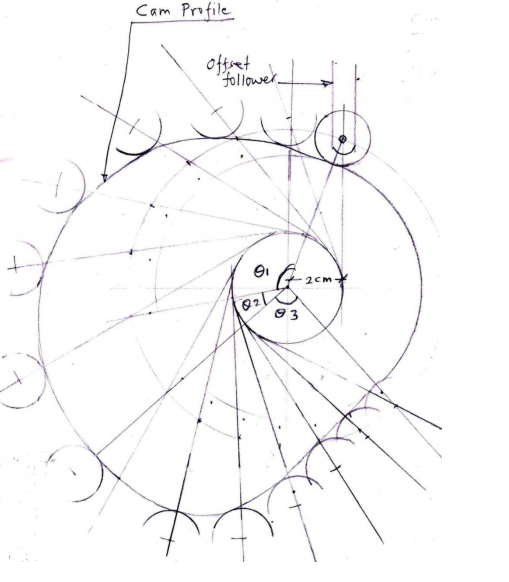

Draw the profile of cam operating a roller reciprocating follower with the following data : Minimum radius of cam = 25 mm lift = 30 mm Roller diameter = 15 mm The cam lifts the follower for 120owith SHM followed by a dwell period of 30o. Then the follower lowers down during 150o of the cam rotation with uniform acceleration and deceleration followed by a dwell period. Answer:

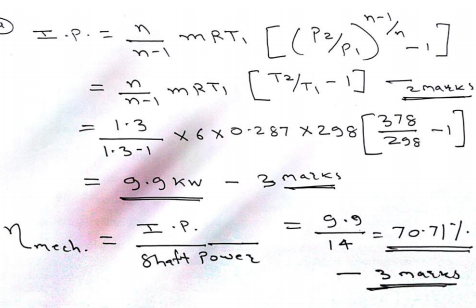

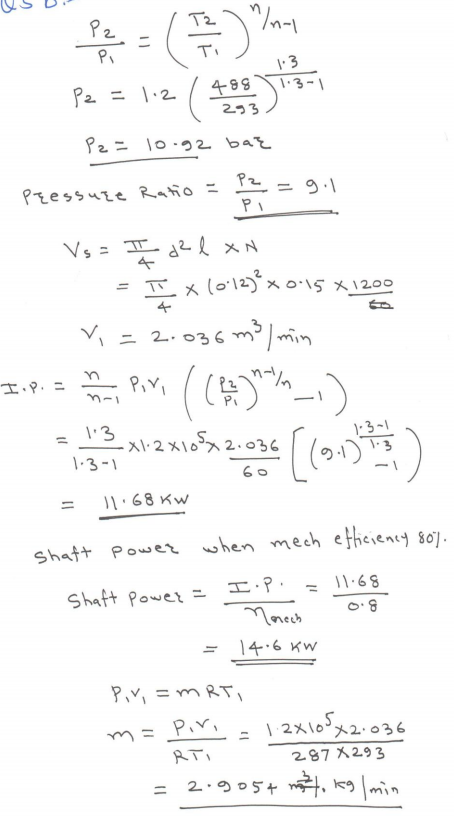

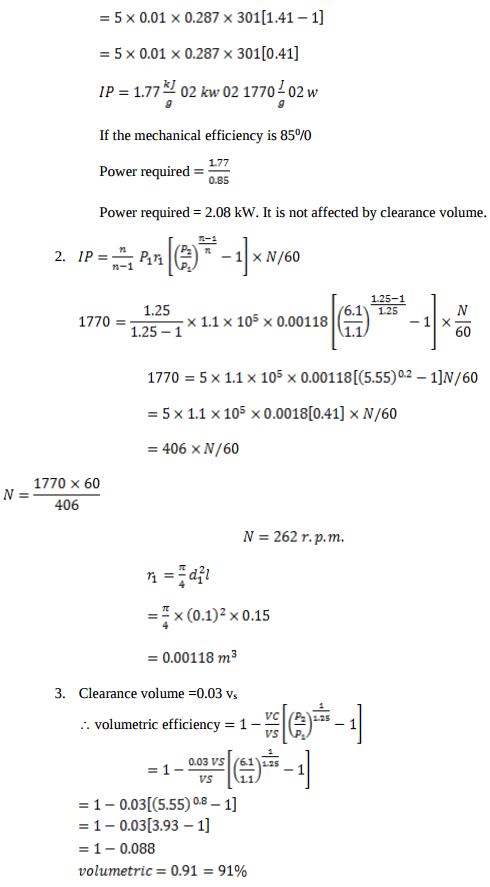

|

8 |

view | |||||||||||||||

| Q 5 b ) |

Question:

What do you mean by ‘Perfect Intercolling’ ? Explain with the help of P.V. diagram. Answer:

|

8 |

view | |||||||||||||||

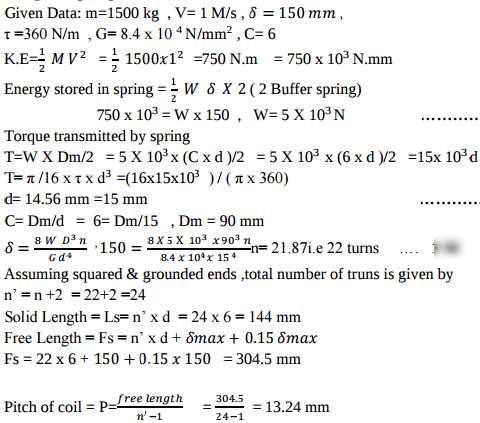

| Q 5 b ) |

Question:

A railway wagon having 1500 kg mass and moving at 1 m/s velocity dashes against a bumper consisting of two helical springs of spring index 6. The springs, which get compressed by 150 mm while resisting a dash made of spring steel having allowable shear stress of 360 N/mm2 and modulus of rigidity 8.4 104 N/mm2 . Design the helical coil spring with circular crosssection of spring wire. Answer:

|

8 |

view | |||||||||||||||

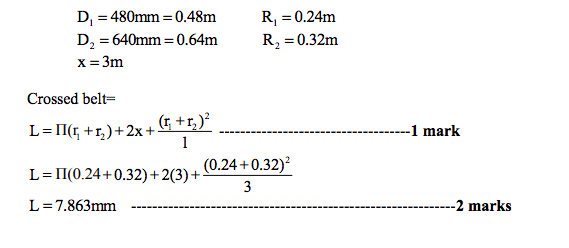

| Q 5 c ) |

Question:

Two parallel shafts, connected by a crossed belt, are provided with pulleys 480 mm and 640 mm in diameters. The distance between the centre lines of the shafts is 3 m. Find by how much the length of the belt should be changed if it is desired to alter the direction of rotation of the driven shaft. Answer:

|

8 |

view | |||||||||||||||

| Q 5 c ) |

Question:

Explain the working of ‘Turbo-Prop’ engine with neat sketch. Answer:

|

8 |

view | |||||||||||||||

| Q 5c)(i) |

Question:

Show that the efficiency of self locking screw is less than 50% Answer:

|

8 |

view | |||||||||||||||

| Q 5c)(ii) |

Question:

State any four advantages of ball bearings over plain journal bearings. Answer:

|

8 |

view | |||||||||||||||

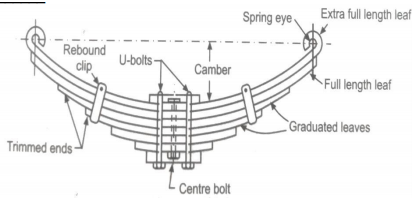

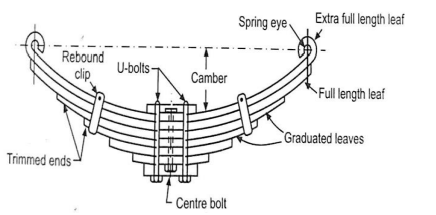

| Q 6 ) |

Question:

Draw a neat sketch of leaf spring of semi-elliptical type and name its parts. Answer:

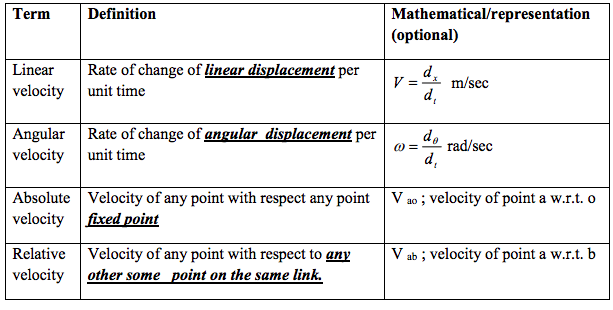

|

4 |

view | |||||||||||||||

| Q 6 a ) |

Question:

State the following term : i) Tonnes of refrigeration ii) COP Answer:

|

4 |

view | |||||||||||||||

| Q 6a)(i) |

Question:

Explain steep and creep phenomenon in belts. Answer:

|

4 |

view | |||||||||||||||

| Q 6a)(ii) |

Question:

Explain single cylinder 4-stroke I.C. engine using turning moment diagram. Answer:

|

4 |

view | |||||||||||||||

| Q 6 b ) |

Question:

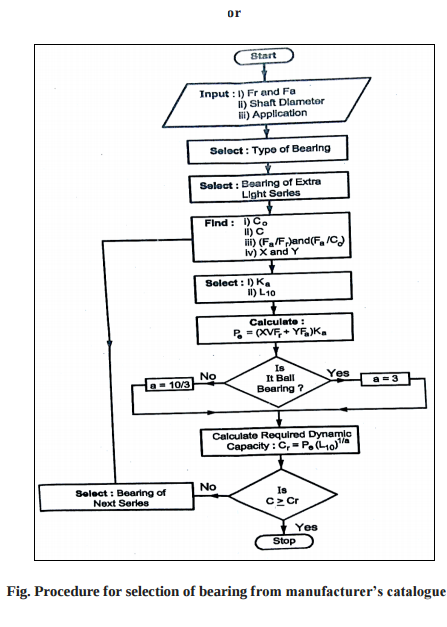

Explain different forms of threads with their relative advantages and applications. Answer:

|

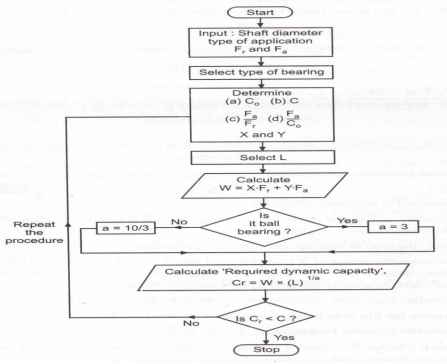

|||||||||||||||||

|

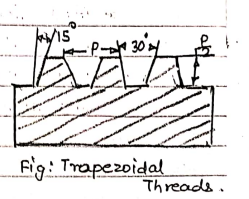

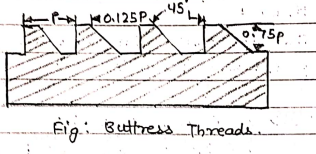

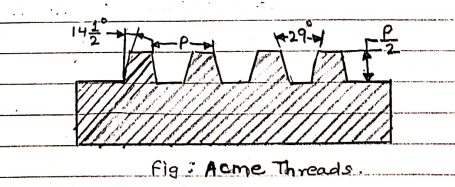

Screw Form |

Characteristic |

Application |

||||||||||||||||

|

Sq. Thread

|

No side thrust Higher efficiency |

Used for general purpose power transmission |

||||||||||||||||

|

Trapezoidal Threads |

Stronger than square threads Easy to manufacture Wear compensation |

Used for higher power transmission |

||||||||||||||||

|

ACME threads |

Stronger than square threads Easy to manufacture Wear compensation |

Used for higher power transmission |

||||||||||||||||

|

Buttress threads |

Can bear very heavy load in one direction |

Used to handle heavy forces in one direction, like in truck jack |

4 |

view | ||||||||||||||

| Q 6 b ) |

Question:

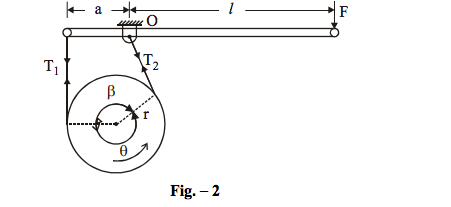

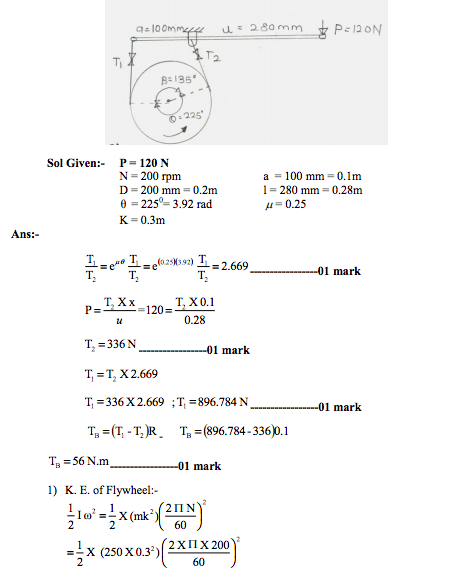

A simple band brake shown in figure 2 is applied to a shaft carrying a flywheel of mass 250 kg and of radius of gyration 300 mm. The shaft speed is 200 rpm. The drum diameter is 200 mm and the coefficient of friction is 0.25. The dimensions a and l are 100 mm and 280 mm respectively and the angle β = 135o. Determine (i) the brake torque when a force of 120 N is applied at the lever end. (ii) the number of turns of the flywheel before it comes to rest. (iii) the time taken by flywheel to come to rest.

Answer:

|

8 |

view | |||||||||||||||

| Q 6 b ) |

Question:

Why majority of air compressors available in the market are multi staged ? Explain Answer:

|

4 |

view | |||||||||||||||

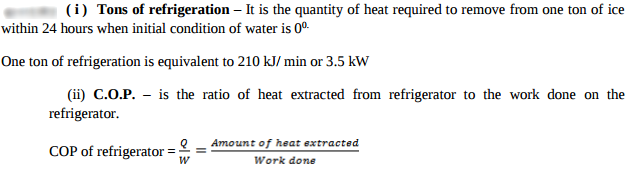

| Q 6 c ) |

Question:

A conical pivot with angle of cone as 100o, supports a load of 18 kN. The external radius is 2.5 times the internal radius. The shaft rotates at 150 rpm. If the intensity of pressure is to be 300 kN/m2 and coefficient of friction as 0.05, what is the power lost in working against the friction ? Answer:

|

8 |

view | |||||||||||||||

| Q 6 c ) |

Question:

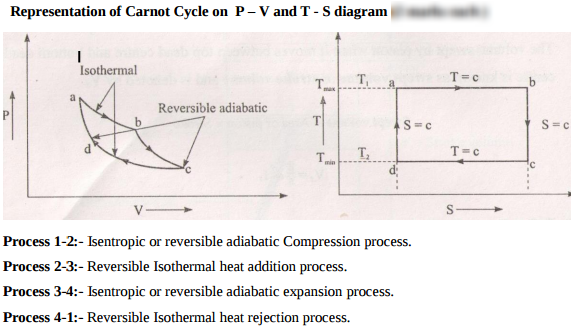

Represent Carnot cycle on P-V and T-S diagram Answer:

|

4 |

view | |||||||||||||||

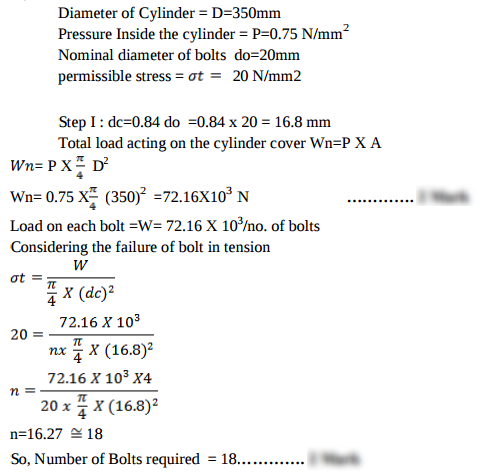

| Q 6 c ) |

Question:

Determine the size of bolt in the cylinder head of a steam engine. The engine cylinder has a bore of 400 mm and the maximum steam pressure to which the cylinder is subjected is 1.5 N/mm2 . Cylinder head is held on the cylinder by 16 number of bolts. The permissible tensile stress for the bolt material is 25 N/mm2 Answer:

|

4 |

view | |||||||||||||||

| Q 6 d ) |

Question:

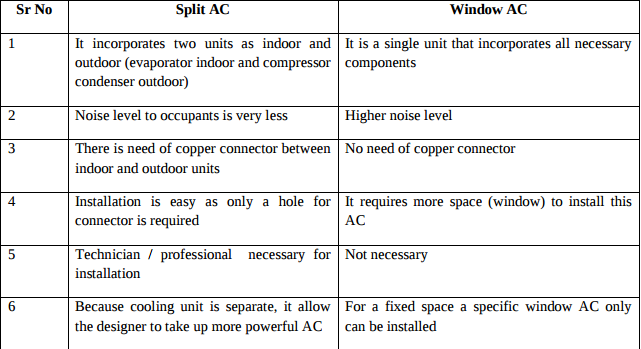

Compare between window air conditioner and split air conditioner (any four) Answer:

|

4 |

view | |||||||||||||||

| Q 6 d ) |

Question:

State any four disadvantages of rolling bearings as compared to journal bearings Answer:

|

4 |

view | |||||||||||||||

| Q 6 e ) |

Question:

Explain any one method to improve thermal efficiency of gas turbine with the help of block diagram. Answer:

+ + |

4 |

view |

| Que.No | Question/Problem | marks | Link |

|---|---|---|---|

| Q ) |

Question:

Explain with neat sketch working of lobe type air compressor. Answer:

|

4 |

view |

| Q 1a)(a) |

Question:

State four assumptions made for air standard cycle. Answer:

|

4 |

view |

| Q 1a)(b) |

Question:

A two stage air compressor with perfect intercooling takes in air at 1 bar pressure and 27 °C. The law of compression in both the stages is Pv1.3 = constant. The compressed air is delivered at 9 bar from the H.P. Cylinder to an air receiver. Calculate per kg. of air i) The minimum work done. ii) The heat rejected to the intercooler. Answer:

|

4 |

view |

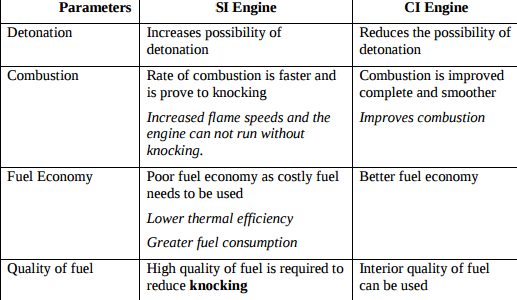

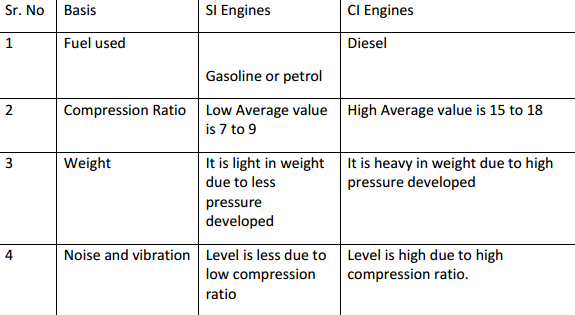

| Q 1a)(c) |

Question:

Compare SI and CI engine on the basis of i) fuel used, ii) Compression ratio, iii) Weight, iv) Noise and vibration Answer:

|

4 |

view |

| Q 1a)(i) |

Question:

What is stress concentration? State its significance in design of machine elements Answer:

|

4 |

view |

| Q 1a)(i) |

Question:

Define Kinematic link with one example. Answer:

|

2 |

view |

| Q 1a)(i) |

Question:

Write any four applications oil hydraulic systems Answer:

|

4 |

view |

| Q 1a)(ii) |

Question:

Name different mechanisms generated from a single slider crank chain. Answer:

|

2 |

view |

| Q 1a)(ii) |

Question:

What are the effects of contaminants in the oil? Answer:

|

4 |

view |

| Q 1a)(ii) |

Question:

Write the design procedure of knuckle joint. Answer:

|

4 |

view |

| Q 1a)(iii) |

Question:

Draw a general layout of pneumatic system and state the function of components Answer:

|

4 |

view |

| Q 1a)(iii) |

Question:

Draw a neat sketch of flexible flange coupling and label its main components. Answer:

|

4 |

view |

| Q 1a)(iii) |

Question:

State the advantages of roller follower over knife edge follower. Answer:

|

2 |

view |

| Q 1a)(iv) |

Question:

Draw the hydraulic circuit showing control of DA cylinder. Using 4 × 2 DC valve. Explain the working in brief. Answer:

|

4 |

view |

| Q 1a)(iv) |

Question:

Draw neat labeled sketches of Acme and square thread profile and state its relative characteristics. Answer:

|

4 |

view |

| Q 1a)(iv) |

Question:

Define slip and creep in case of belt drive. Answer:

|

2 |

view |

| Q 1a)(v) |

Question:

Give four advantages of chain drive over belt drive. Answer:

|

2 |

view |

| Q 1a)(vi) |

Question:

State the effect of centrifugal tension on power transmission. Answer:

|

2 |

view |

| Q 1a)(vii) |

Question:

Define fluctuation of energy and coefficient of fluctuation of energy. Answer:

|

2 |

view |

| Q 1a)(viii) |

Question:

State the adverse effect of imbalance of rotating elements of machine. Answer:

|

2 |

view |

| Q 1b)(a) |

Question:

A four cylinder engine running at 1200 rpm delivers 20 kW. The average torque when one cylinder was cut is 110 N.m. Find the indicated thermal efficiency if the calorific value of the fuel is 43 MJ/Kg and the engine uses 360 gm. of gasoline (fuel) per kW. hr. Answer:

|

6 |

view |

| Q 1b)(b) |

Question:

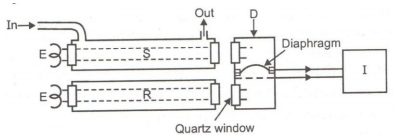

Explain with neat sketch working of non dispersive infra red (NDIR) gas analyser. Answer:

|

6 |

view |

| Q 1b)(i) |

Question:

Draw actual hydraulic system and explain its working. Answer:

|

6 |

view |

| Q 1b)(i) |

Question:

State and explain main considerations in machine design. Answer:

|

6 |

view |

| Q 1b)(i) |

Question:

State any four inversions of single slider crane chain. Describe any one with neat sketch. Answer:

|

4 |

view |

| Q 1b)(ii) |

Question:

Explain with neat sketch the working of rotary spool type DC valve. Answer:

|

6 |

view |

| Q 1b)(ii) |

Question:

A hollow shaft is required to transmit 50 kW power at 600 rpm. Calculate its inside and outside diameters if its ratio is 0.8. Consider yield strength of material as 380N/mm2 and factor of safety as 4. Answer:

|

6 |

view |

| Q 1b)(ii) |

Question:

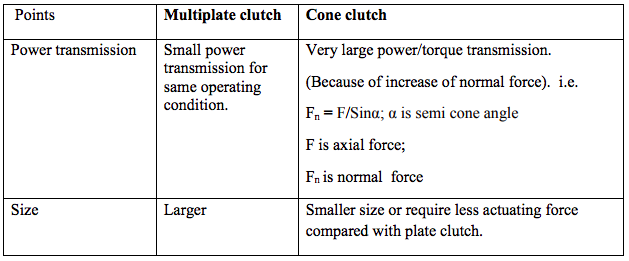

Compare multiplate clutch with cone clutch on the following basis. (1) Power Transmission (2) Size Answer:

|

4 |

view |

| Q 1b)(iii) |

Question:

The central distance two shaft is 4m having two pulleys with diameter having 500mm and 700mm respectively find the length of belt required - (1) for open belt drive (2) for cross belt drive Answer:

|

4 |

view |

| Q 2 a ) |

Question:

Explain a scotch yoke mechanism with a neat sketch. Answer:

|

4 |

view |

| Q 2 a ) |

Question:

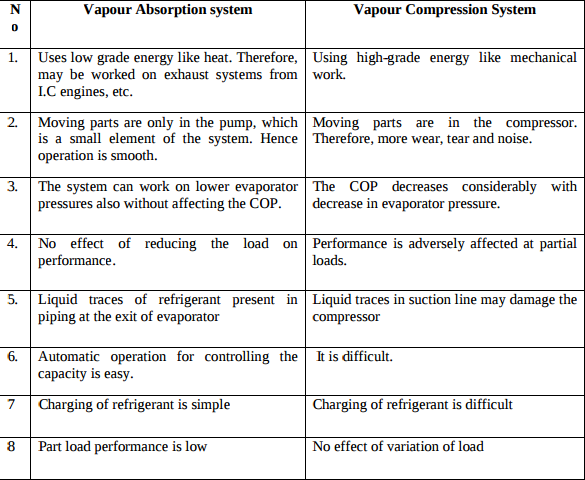

Differentiate vapour compression and vapour absorption refrigeration system. (min. eight points of difference) Answer:

|

8 |

view |

| Q 2 a ) |

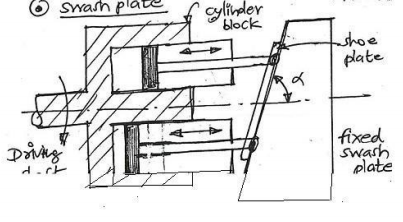

Question:

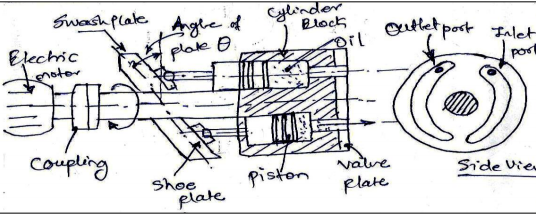

What is swash plate? What is its use? What will happen if we change the angle of swash plate? Explain with sketch Answer:

|

8 |

view |

| Q 2 a ) |

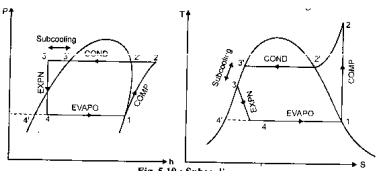

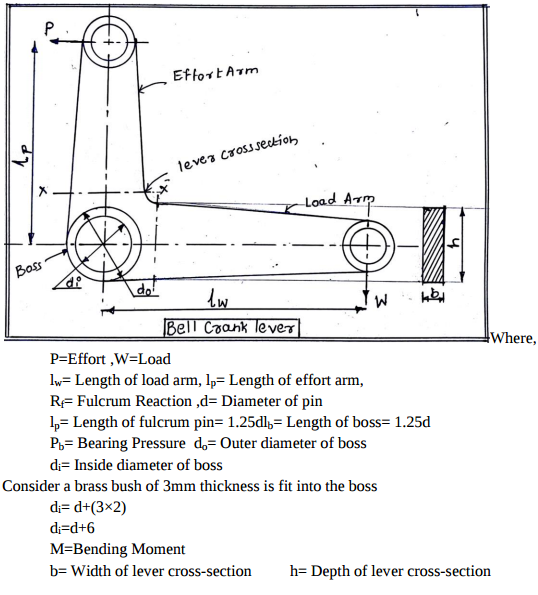

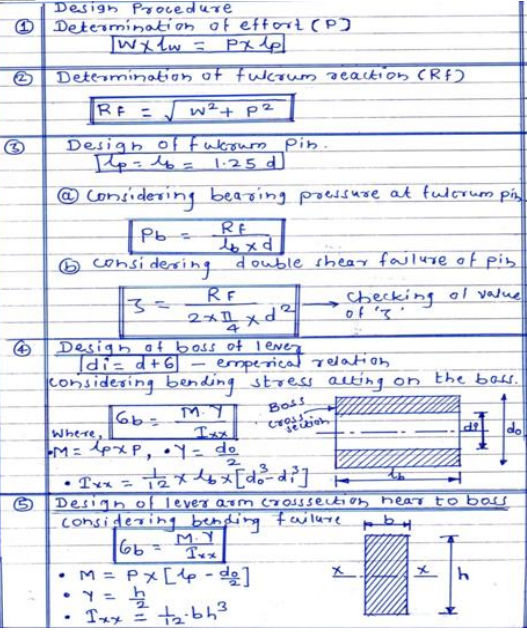

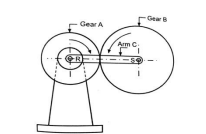

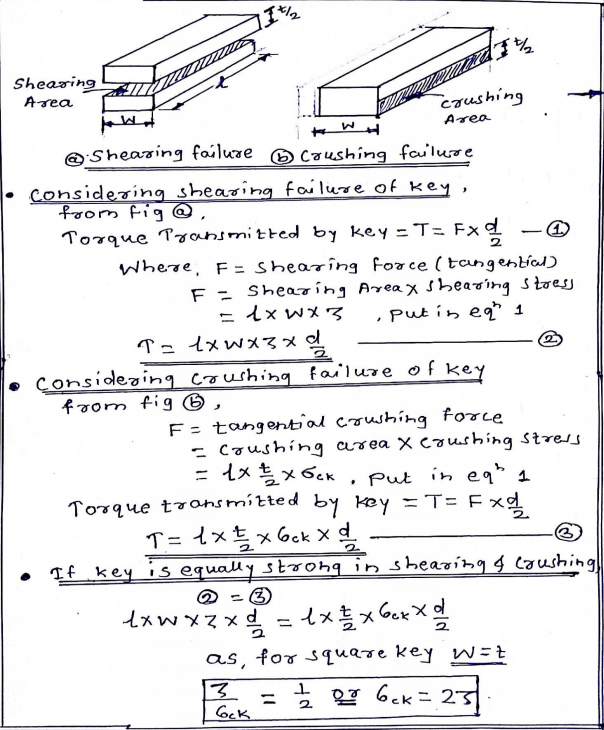

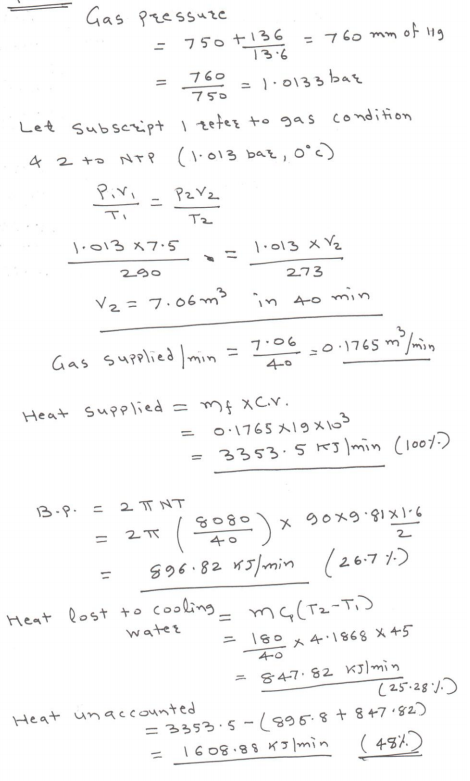

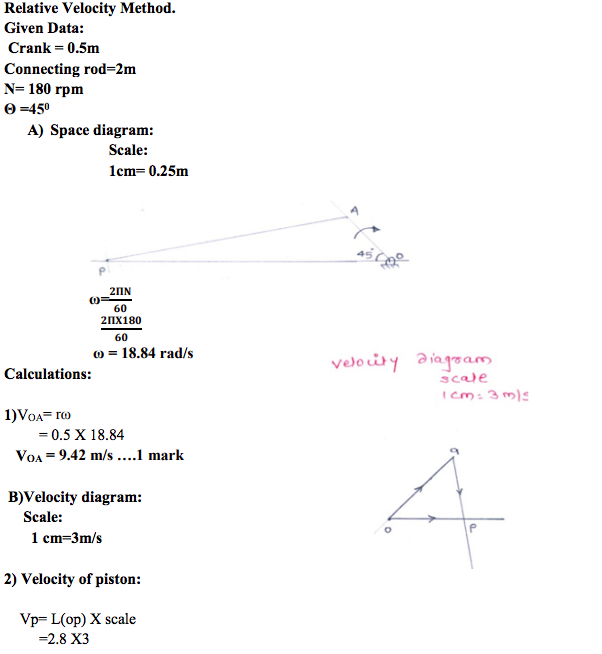

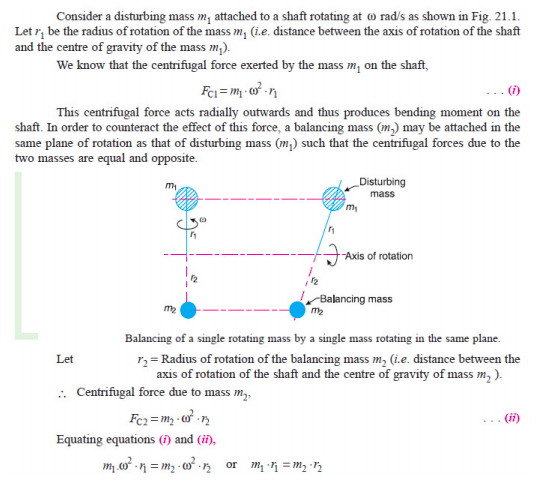

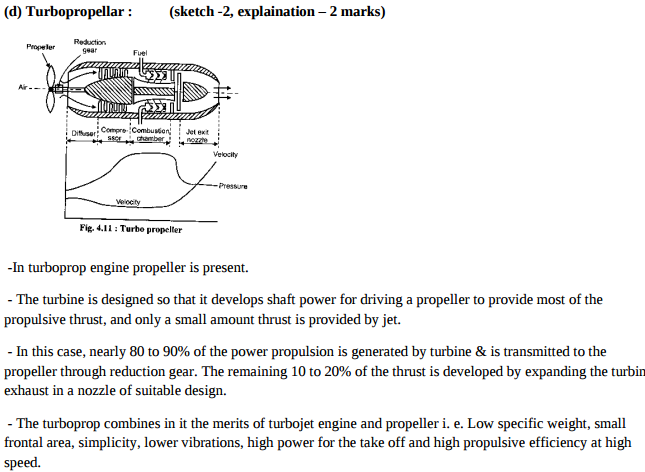

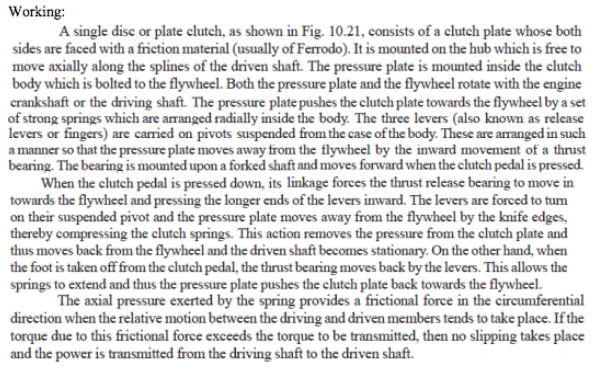

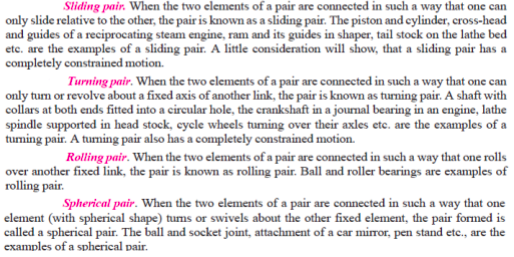

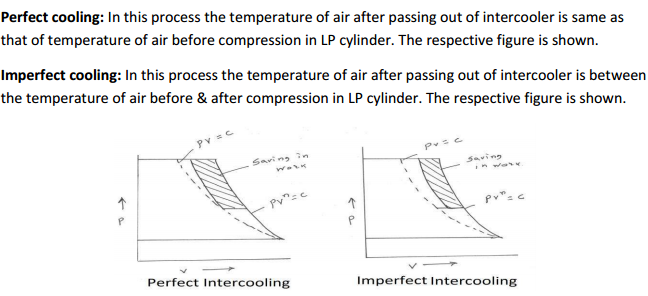

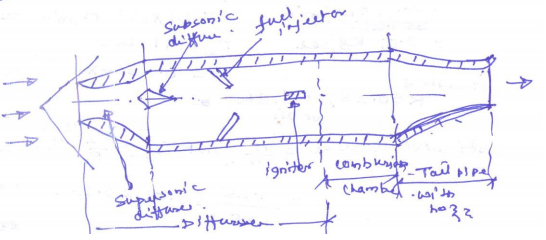

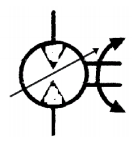

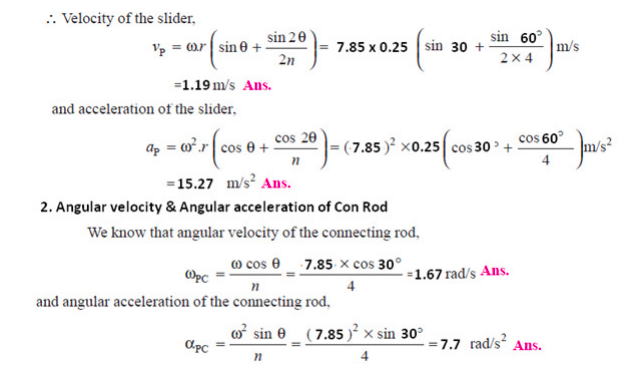

Question: